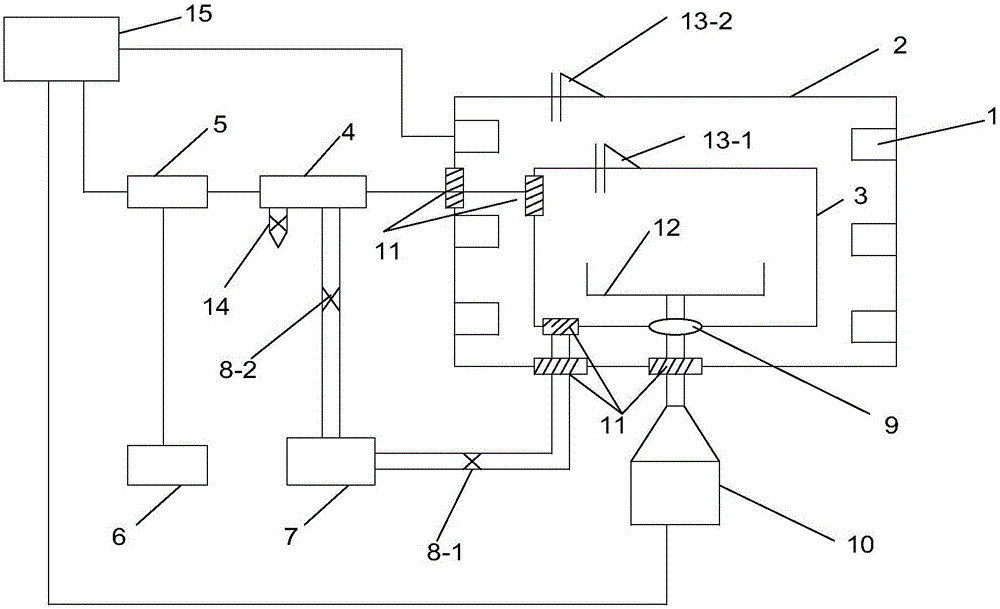

Microwave vacuum freeze drying equipment and material drying method

A technology of microwave vacuum and drying equipment, which is applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc. Field uniformity, avoids glow discharge, overcomes time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

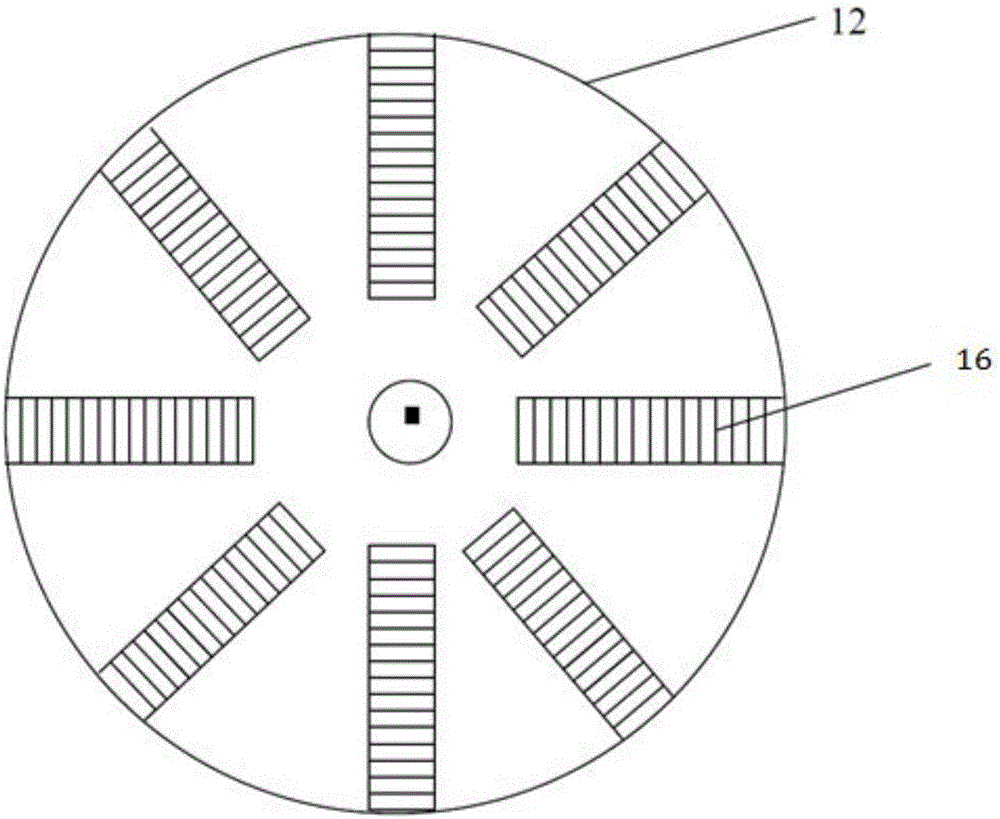

[0059] In this example, use figure 1 The equipment shown freeze-dries banana chunks and operates as follows:

[0060] Open the microwave chamber door 13-2 and the freeze-drying chamber door 13-1, and place some banana pieces to be freeze-dried on the miniature conveyer belt 16 on the turntable 12 respectively. Close the freeze-drying bin door 13-1 and the microwave bin door 13-2 in sequence. The banana pieces are pre-cut into 1cm×1cm×1cm cubic pieces with a distance of about 0.5cm between them, and are evenly arranged on the miniature transmission belt 16 .

[0061] Open the refrigeration system 7 and valves 8-1 and 8-2, freeze the banana pieces on the turntable 12, and make the temperature of the vacuum water catch system drop to -20°C rapidly.

[0062] Program the microcomputer central control system so that it can automatically adjust the change mode of microwave power, the change mode and range of pressure, the matching mode of relative change between pressure and microw...

Embodiment 2

[0072] This embodiment is used as a preferred embodiment of the present invention, and the specific design method is the same as that of Embodiment 1, which is used to freeze-dry the cellulose SiO2 composite airgel material. The specific operation process is as follows:

[0073]Open the microwave chamber door 13-2 and the freeze-drying chamber door 13-1, and place a number of cellulose-SiO2 composite wet gels to be freeze-dried on the micro conveyor belt 16 on the turntable 12 respectively. Close the freeze-drying bin door 13-1 and the microwave bin door 13-2 in sequence. The wet gels are cubic blocks or plates with a distance of about 2 cm between them, and are evenly arranged on the miniature transmission belt 16 .

[0074] Turn on the refrigeration system 7 and the valves 8-1 and 8-2, freeze the wet gel on the turntable 12, and rapidly reduce the temperature of the vacuum water trapping system to -45°C.

[0075] Program the microcomputer central control system so that it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com