Crystal growth method and application thereof

A crystal growth and nanocrystal technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of low dislocation density, crystal consistency and poor yield, so as to reduce laser power and crystal growth speed Fast and high crystal growth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment relates to a crystal growth method, comprising the following steps:

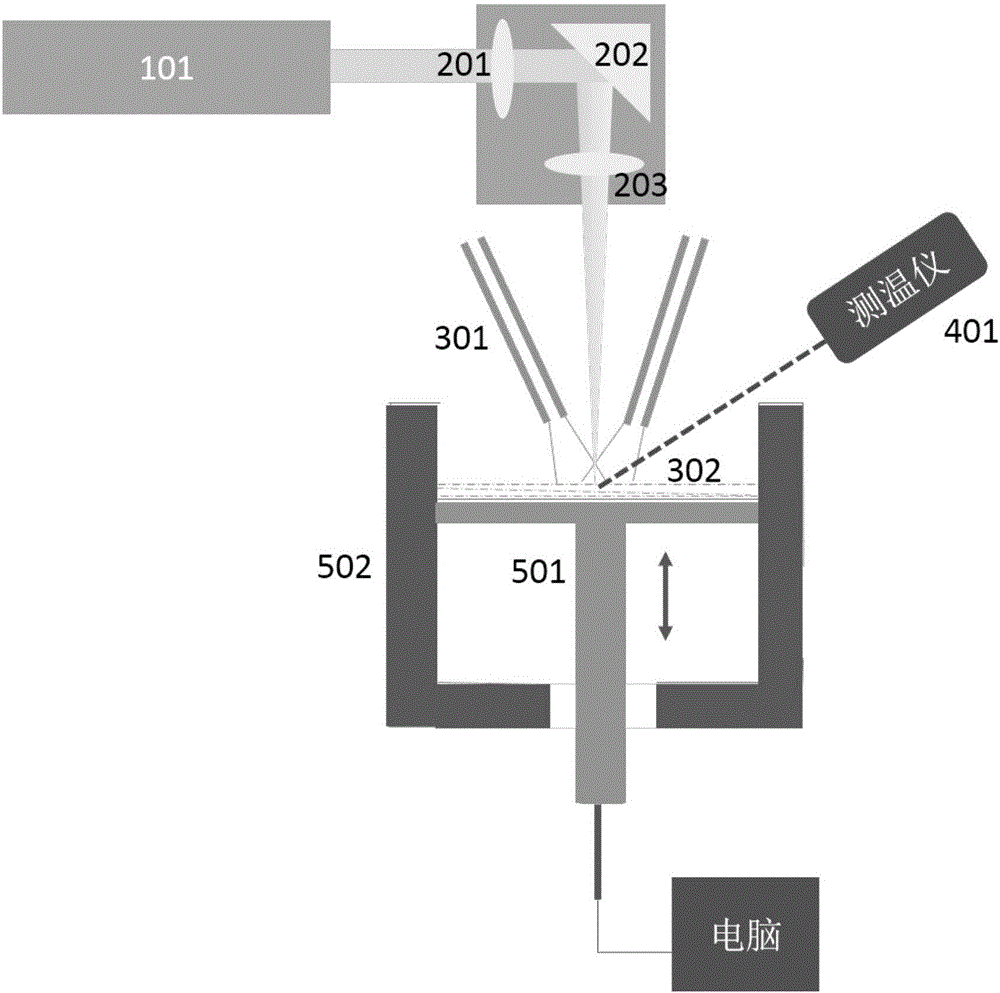

[0040] Calcium fluoride (GaF 2 ) powder and ytterbium oxide (Yb 2 o 3 ) powder weighed 30g according to the molar ratio of 1:0.075, wherein the mass of calcium fluoride powder was 21.8g, and the mass of ytterbium oxide powder was 8.2g. Put the powder into the mortar and stir well, so that the powder can be mixed together as much as possible. The mixed powder is placed in the annular powder feeder 301 , and the powder is uniformly output on the laser sintering platform 302 through the nozzle of the annular powder feeder. The annular powder feeder is controlled by an external program, which can change the powder feeding time and powder feeding rate.

[0041] The entire set of devices is placed in a sealed environment 502 filled with argon (Ar) atmosphere after being evacuated. The laser 101 used in this experiment is a semiconductor laser, the output laser wavelength is 976nm, and t...

Embodiment 2

[0045] A kind of preparation method of pottery that present embodiment relates to, comprises the steps:

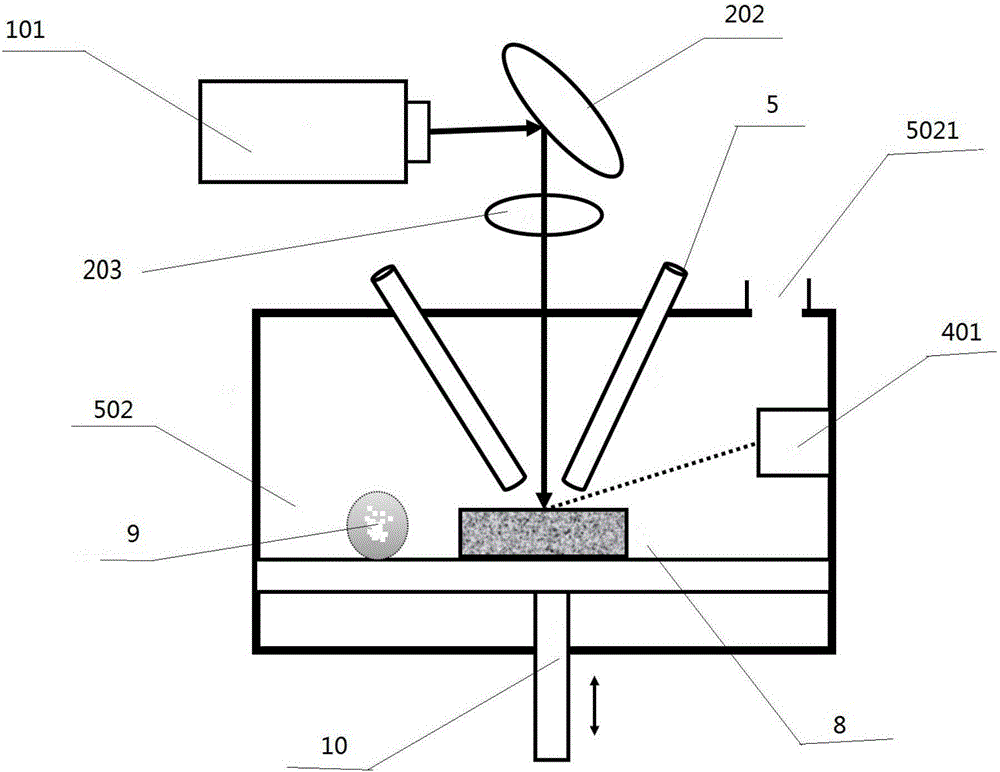

[0046] Alumina (Al 2 o 3 ) powder and ytterbium oxide (Yb 2 o 3 ) powder weighed 50g according to the molar ratio of 1:1, fully ground and stirred evenly. The mixed powder passes through the powder transmission conduit 5 and is evenly output on the movable working platform 10 , and the powder surface is flattened and compacted by the ball mill 9 to form a regular tablet shape 8 .

[0047] The reaction chamber 502 is filled with argon (Ar) gas through the gas inlet 5021, so that the ceramic growth process is in an inert gas atmosphere. Laser 1 is a semiconductor laser, the output laser wavelength is 976nm, and the laser is output through the output end of the coupling fiber. The laser light passes through a reflector 202 to change the laser transmission direction, and then passes through a focusing lens 203 to focus the light spot. The infrared thermometer 401 monitor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com