A Continuous Casting Process of High Straightening Strain C-Class Angle Steel

A continuous casting process and angle steel technology, which is applied in the field of large straightening strain C grade angle steel continuous casting process, can solve problems such as corner cracking, achieve the effects of reducing the generation of transverse cracks, preventing bonding, and promoting heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

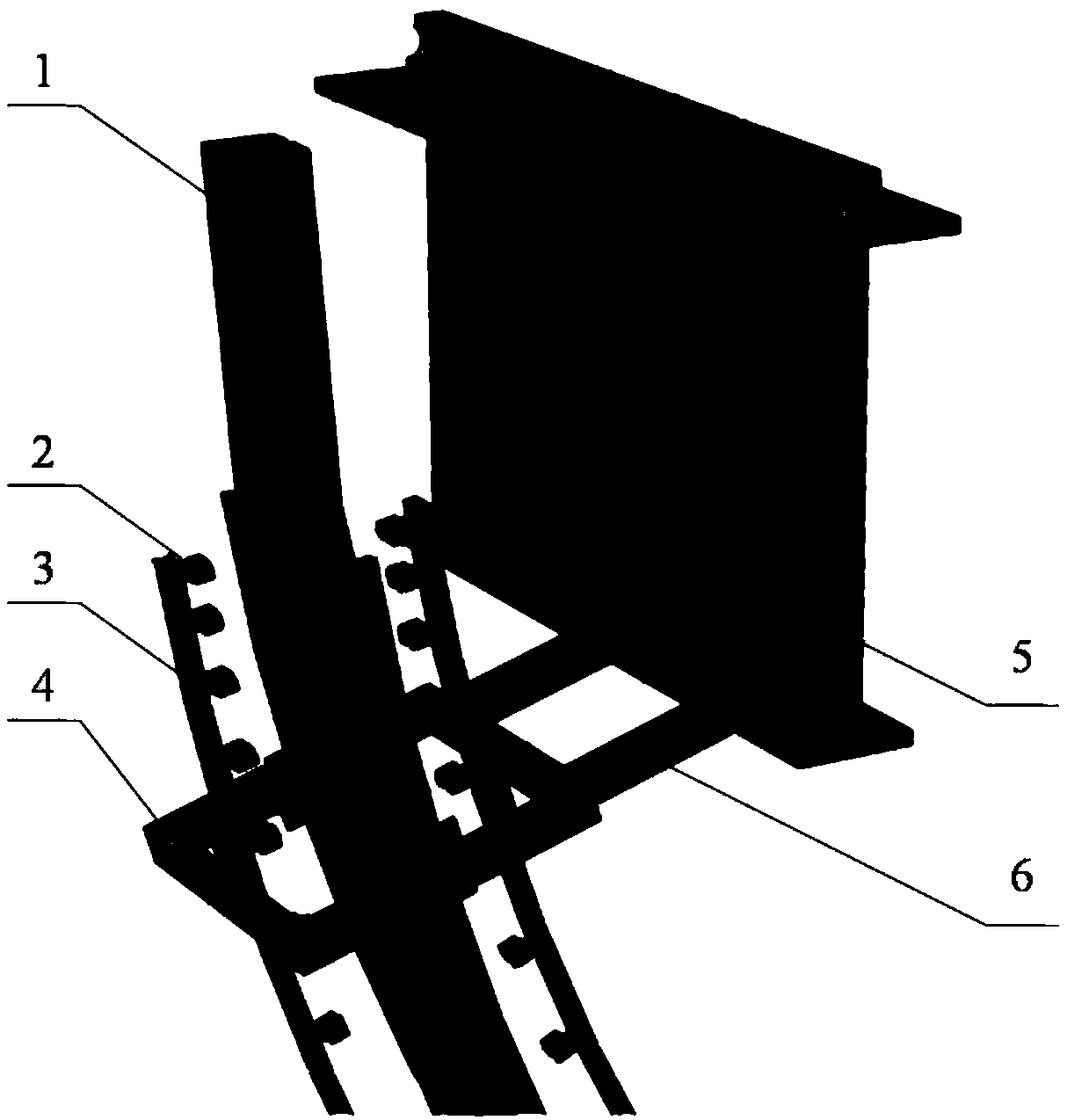

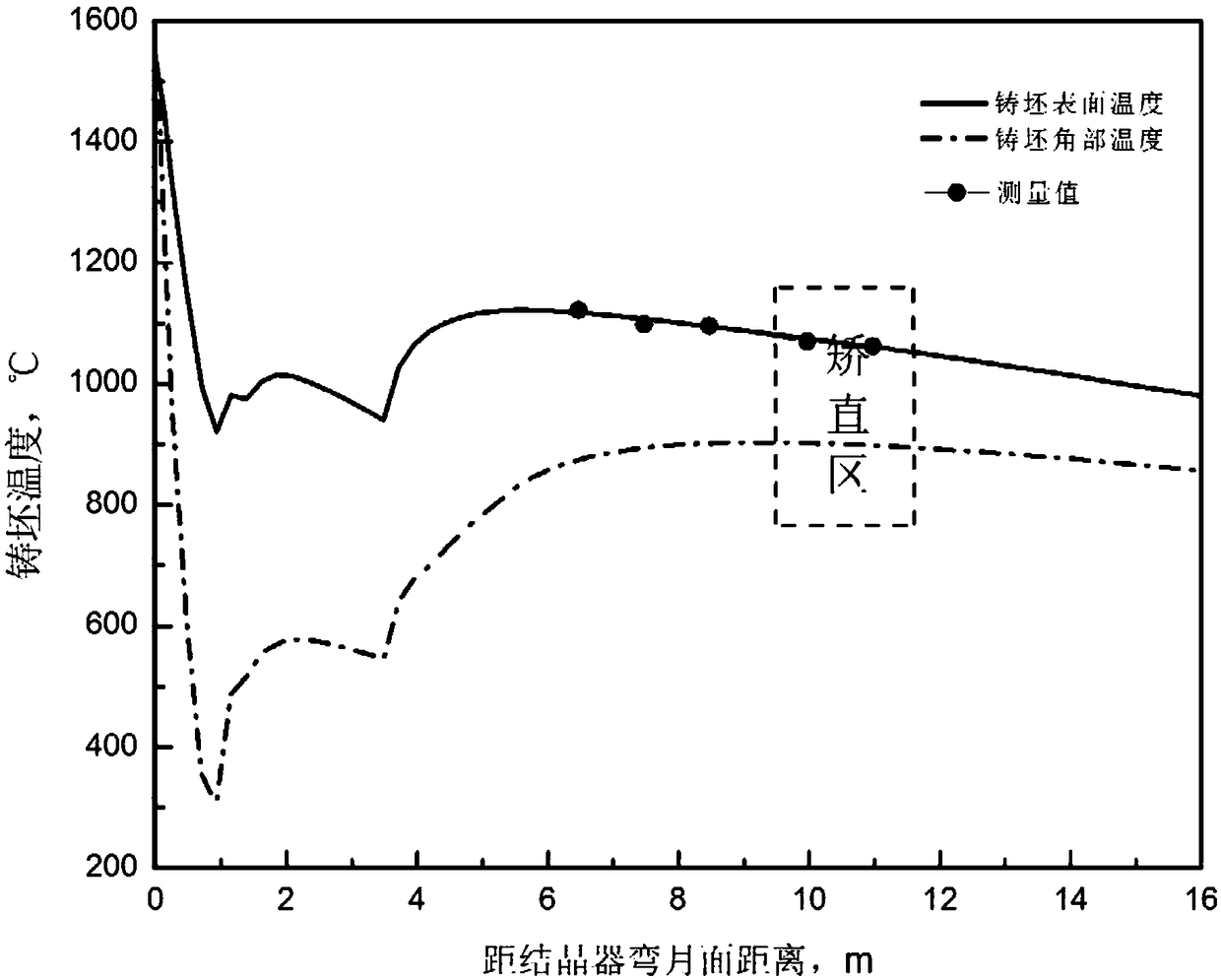

[0058] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

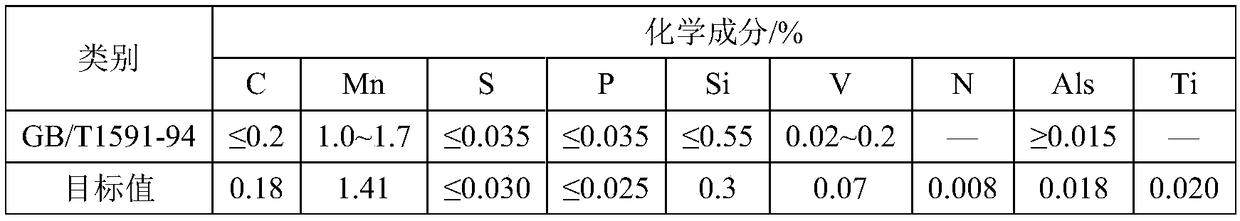

[0059] A large straightening strain C grade angle steel continuous casting process, the composition and mass percentages of molten steel used in the large straightening strain C grade angle steel continuous casting process are: C: 0.16-0.19%, Mn: 1.38-1.45%, Si: 0.25~0.35%, S, P≤0.030%, V: 0.06~0.09%, N: 0.006~0.010%, Al: 0.017~0.022%, Ti: 0.02~0.04%;

[0060] The continuous casting process of large straightening strain C grade angle steel includes the following steps:

[0061] S1, converter smelting process;

[0062] S2, ladle refining furnace refining process;

[0063] S3, continuous casting process;

[0064] S4, heating and rolling process;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com