Process for producing nickel iron particles by carrying out reducing calcination on laterite-nickel ore through rotary kiln one-step method

A technology of laterite nickel ore and rotary kiln, which is applied in the field of metallurgical technology, can solve the problems of fine nickel-iron alloy particles, high nickel content in tailings, and ring formation, and achieve the effects of preventing secondary oxidation, simple process technology, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of rotary kiln one-step reduction roasting laterite nickel ore produces the technology of ferronickel particle, it comprises the following steps:

[0019] 1) Batching and pelletizing: After mixing the dried and crushed laterite nickel ore with carbonaceous reducing agent, magnesium supplement and vulcanizing agent, the balls are pressed on a briquetting machine to form mixed pellets; wherein, the laterite nickel The amount of ore accounts for 75% of the total weight of the mixture, and the amount of the carbonaceous reducing agent accounts for 20% of the total weight of the mixture; the amount of the magnesium supplement accounts for 0% of the total weight of the mixture; the vulcanizing agent The dosage accounts for 5% of the total weight of the mixture;

[0020] 2) Reduction roasting: send the mixed pellets into the rotary kiln for roasting, the temperature in the rotary kiln is gradually raised from 300°C to 1250°C, the reaction temperature of the reduction se...

Embodiment 2-6

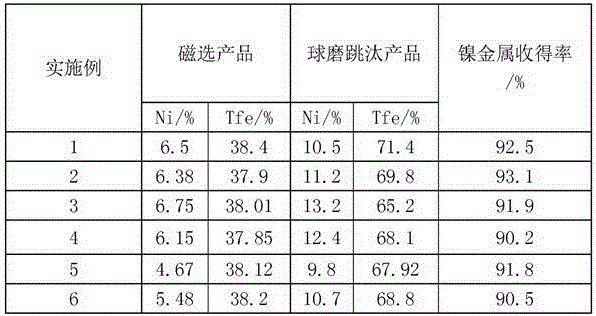

[0025] Examples 2-6 take the same steps as in Example 1, the difference lies in the proportion of raw materials used in step 1) in the mixed pellets, and the temperature of the reduction and roasting section in the rotary kiln is different. The specific data are shown in Table 1:

[0026] Table 1

[0027]

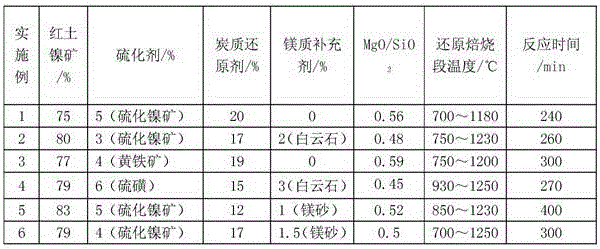

[0028] The recovery rates of nickel-iron metal in the products obtained in Examples 1-6 of the present invention are shown in Table 2.

[0029] Table 2

[0030]

[0031] As can be seen from Table 2, adopt the rotary kiln one-step method of the present invention to reduce and roast laterite nickel ore to produce the technique of ferronickel particle its ferronickel average recovery rate reaches more than 90%,

[0032] The present invention adds vulcanizing agent ore in the batching and pelletizing stage to enrich the sulfur ions decomposed in the vulcanizing agent on the surface of the metal particles under high temperature conditions to reduce the melting point and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com