A low-temperature fast-curing organic resin carrier for printed electronics and its preparation method and application

An organic resin and rapid curing technology, which is applied in the field of information electronic material preparation, can solve problems such as dependence, and achieve the effects of improving compatibility, good reproducibility, and prolonging the rate of change in resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The method for preparing a low-temperature fast-curing organic resin carrier for printed electronics in an embodiment of the present invention includes the following steps:

[0029] (1) First add the solvent into the barrel in proportion, then add the organic resin into the barrel in proportion under low-speed stirring, increase the stirring speed of the disperser, and keep the system temperature within 80°C. After the organic resin is completely dissolved, cool the resin liquid to At room temperature, then add the curing agent and fast curing accelerator in proportion and stir evenly, and the low-temperature fast-curing organic resin carrier for printed electronics can be used;

[0030] (2) For the electronic slurry system that needs to be ground for a long time, the fast curing accelerator is added after the plan is adopted. The filler powder and the organic resin carrier in step (1) are pre-ground to fineness by three rolls, and then the fast curing accelerator is add...

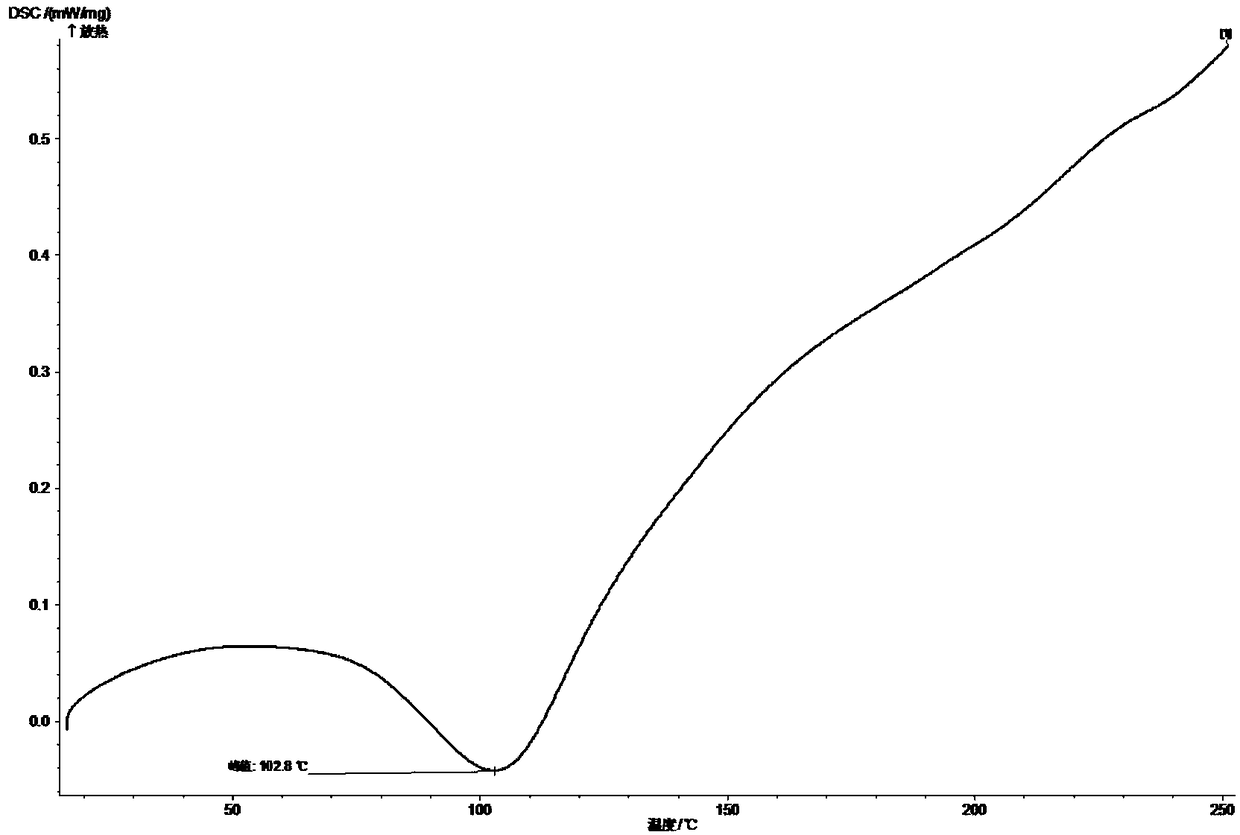

Embodiment 1

[0033] (1-1) The mass percentage of the organic resin carrier is as follows: 35% of the modified polyester resin with a molecular weight of 17000, 49% of the mixed solvent: diethyl adipate / DBE (V:V=1:2), 12 % blocked isocyanate curing agent: NCO content 6.4wt%, unblocking temperature 95°C, 4% fast curing accelerator: titanate chelate / DBU (Wt:Wt=4.5:0.5). First add the solvent into the barrel in proportion, then add the organic resin into the barrel in proportion under low-speed stirring, increase the stirring speed of the disperser, keep the system temperature within 80°C, wait until the organic resin is completely dissolved, cool the resin solution to room temperature, and then Add the curing agent in proportion and stir evenly for use; the rapid curing accelerator is separately in proportion for use.

[0034] (1-2) Weigh raw materials according to the following mass percentage: 70% average particle size 1.0 μm, bulk density 2.4g / cm 3 , The tap density is 4.0g / cm 3 , Dmax≤2...

Embodiment 2

[0036] (2-1) The mass percentage of the organic resin carrier is as follows: 40% of the molecular weight 15000 modified polyester resin, 45% of the mixed solvent: DBE / isophorone (V:V=8:1), 10% of the Blocked isocyanate curing agent: NCO content 12.5wt%, unblocking temperature 120°C, 5% fast curing accelerator: titanate chelate / DMAP (Wt:Wt=4.7:0.3). First add the solvent into the barrel in proportion, then add the organic resin into the barrel in proportion under low-speed stirring, increase the stirring speed of the disperser, keep the system temperature within 80°C, wait until the organic resin is completely dissolved, cool the resin solution to room temperature, and then Add curing agent and fast curing accelerator in proportion and stir evenly for use.

[0037] (2-2) Weigh raw materials according to the following mass percentage: 67% average particle size 8.0 μm, bulk density 0.8g / cm 3 , The tap density is 1.7g / cm 3 , Silver-coated copper powder with a silver content of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com