Wood-plastic coextruded fabric

A kind of fabric and wood-plastic technology, applied in the field of chemical production, can solve the problems of low hardness, low bonding force of wood-plastic core layer, easy separation of cladding material and wood-plastic core layer, etc., to achieve improved weather resistance and high Shore hardness , the effect of strong combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

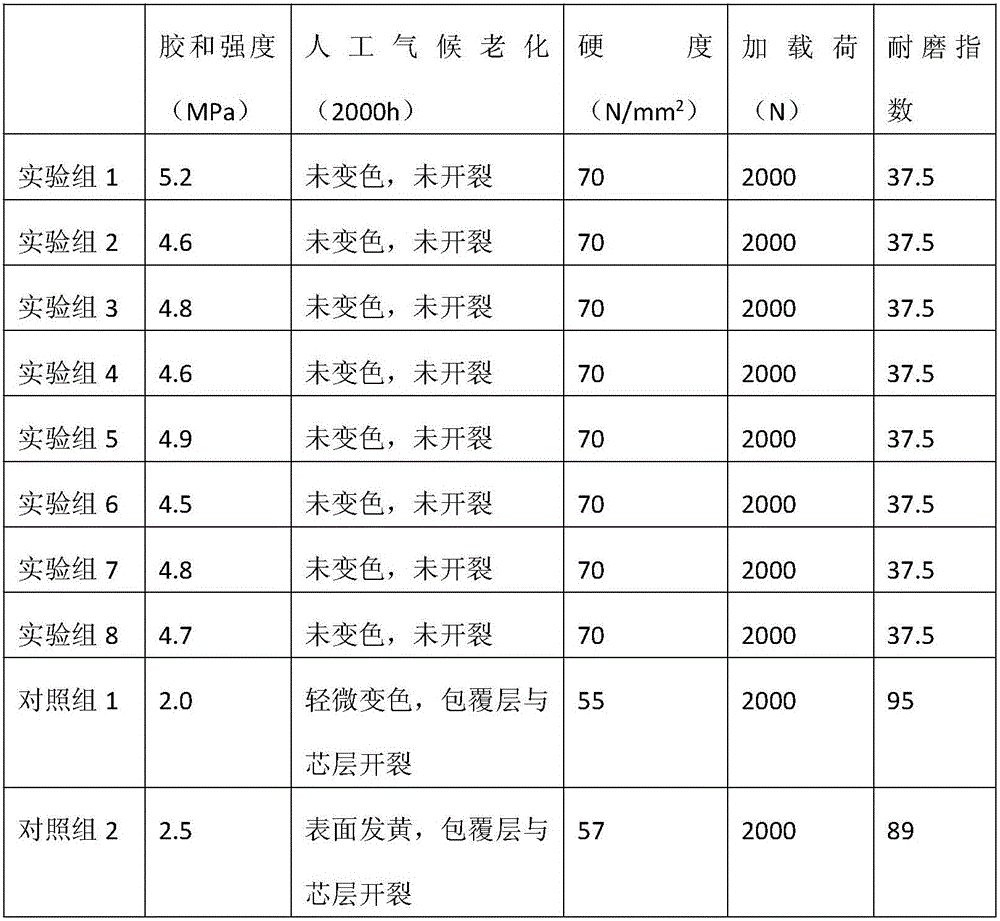

Examples

Embodiment 1

[0010] A wood-plastic co-extrusion fabric, including the following raw materials in weight fractions: linear low-density polyethylene 50%; polypropylene graft 15%; acrylonitrile-butadiene-styrene copolymer 25%; antioxidant 1010 2 %, UV absorber UV326 3%, lubricant EBS 2%, calcium zinc stabilizer 3%.

[0011] In the present embodiment, the polypropylene graft is prepared by the following method: with 2.0wt% maleic anhydride as the graft monomer, 0.5wt% dicumyl peroxide as the initiator, the graft monomer and The initiator is added into 97.5wt% propylene copolymer for reaction and extruded.

[0012] The preparation method steps of wood-plastic co-extrusion fabric are as follows:

[0013] (1) Measure each raw material separately according to the formula;

[0014] (2) Put each raw material into a high-speed mixer, set the rotating speed at 240 rpm, and mix for 3-10 minutes, so that the components are evenly mixed;

[0015] (3) Put the mixed material in step (2) into the silo of...

Embodiment 2

[0017] A wood-plastic co-extruded fabric, comprising the following raw materials by weight: low-density polyethylene 30%; polypropylene graft 20%; polypropylene, nylon 40%; antioxidant 1076 3%, ultraviolet absorber UV326 1% , polyethylene wax 2%, barium sulfate 4%.

[0018] In the present embodiment, the polypropylene graft is prepared by the following method: with 1.0wt% maleic anhydride as the graft monomer, 2.0wt% dicumyl peroxide as the initiator, the graft monomer and The initiator is added to 97wt% homopolypropylene for reaction and extruded.

[0019] The preparation method of the wood-plastic co-extruded fabric is the same as in Example 1.

Embodiment 3

[0021] A wood-plastic co-extruded fabric, comprising the following raw materials by weight: 60% high-density polyethylene; 5% polypropylene graft; 30% nylon; 1% antioxidant 1010, 1% UV absorber UV328, stearin Zinc acid 1%, silicon dioxide 2%.

[0022] In the present embodiment, the polypropylene graft is prepared by the following method: with 3.0wt% maleic anhydride as the graft monomer, 2.0wt% dicumyl peroxide as the initiator, the graft monomer and The initiator is added into 95wt% copolymerized polypropylene for reaction and extruded.

[0023] The preparation method of the wood-plastic co-extruded fabric is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com