Continuous production process for alkaline synthesis of potassium isopropoxide

A production process and a technology for potassium isopropoxide, which are applied in the field of continuous production technology for synthesizing potassium isopropoxide by alkali method, can solve the problem that the continuous production process of potassium isopropoxide synthesis by alkali method is not mentioned, and the free alkali content and product cannot be obtained. Quality fluctuation and other problems, to achieve the effect of being conducive to intelligent operation, stable product quality assurance, and low comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

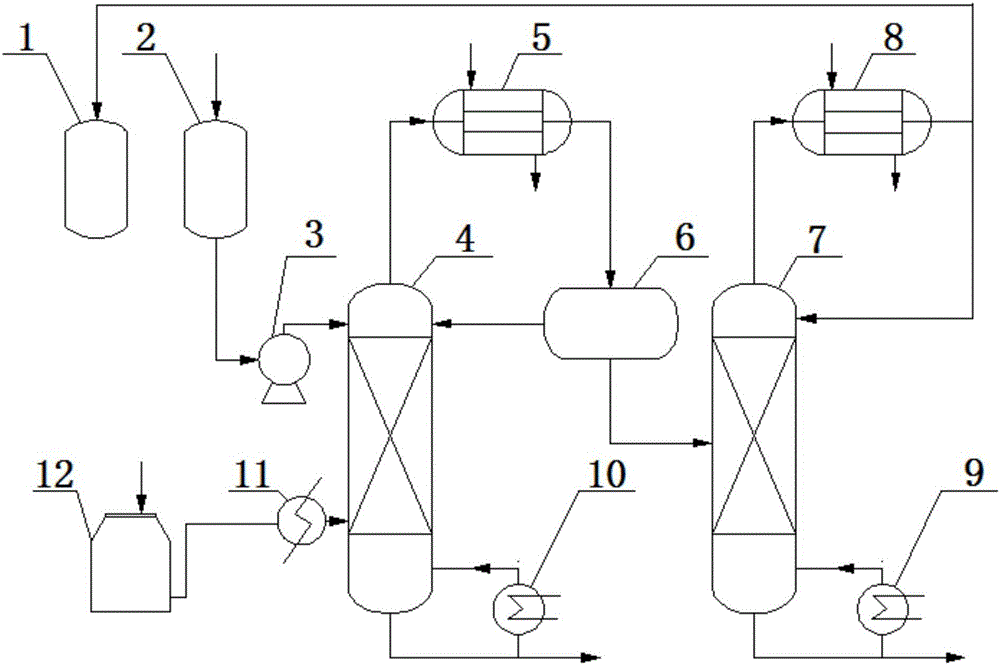

[0026] The specific process of the present invention will now be described through the following embodiments in conjunction with the accompanying drawings.

[0027] A kind of continuous production technique of alkali method synthesis potassium isopropoxide of the present invention, its main technical feature is to adopt azeotropic rectification method dehydration, take cyclohexane as water-carrying agent, take flake potassium hydroxide and isopropanol as Raw materials are used to produce potassium isopropoxide, and the ratio of raw materials isopropanol:cyclohexane:potassium hydroxide=6:3:1.

[0028] A continuous production process for the synthesis of potassium isopropoxide by alkali method, comprising an alcohol alkane solution storage tank 1, an alkali solution storage tank 2, a metering pump 3, a reactive distillation tower 4, a rectification tower condenser 5, and a liquid-liquid phase separator 6. Alkanes recovery tower 7, recovery tower condenser 8, recovery tower reboi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com