Data sampling method for improving finish rolling setting calculation

A technology of data sampling and finishing rolling, applied in calculation, design optimization/simulation, computer-aided design, etc., can solve problems affecting rolling stability and yield, rolling force deviation, large speed deviation, etc., to avoid precision The effect of low precision of rolling setting, ensuring model parameters and control stability, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

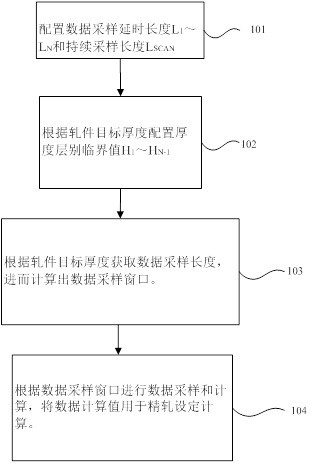

Method used

Image

Examples

Embodiment 1

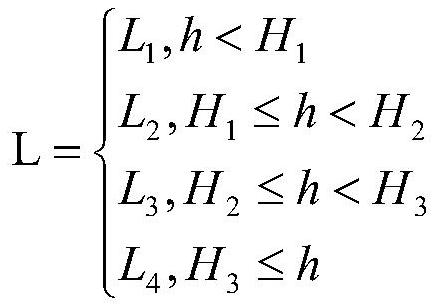

[0032] Configure the data sampling delay length L in a hot rolling production line 1 1.0m, L 2 1.5m, L 3 2.0m, L 4 Bit 2.2m, data sampling length L scan1.0m; thickness critical value H 1 4.0mm, H 2 8.0mm, H 3 12.0mm. When the target thickness is 2.0mm, and the steel grade is SPHC, the temperature data of the head of the intermediate billet needs to be sampled when the finish rolling setting is calculated.

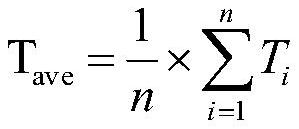

[0033] The target thickness of the product is 2.0mm, which is less than the thickness critical value H1. Calculate the data sampling delay length L=L1, that is, 1.0m. The start position of the data sampling window is 1.0m at the head, and the end position is L+L scan = 2.0m, that is, the data sampling window is the area between 1.0m and 2.0m at the head of the intermediate billet of the rolled piece. The data sampling period is sampling once every 0.1 meters, and a total of 11 sampling values are obtained in the data sampling window, that is, n=11, and the samplin...

Embodiment 2

[0040] Configure the data sampling delay length L in a hot rolling production line 1 1.0m, L 2 1.2m, L 3 1.5m, L 4 1.8m, L 5 2.0m, data sampling length L scan 1.1m; thickness critical value H 1 3.0mm, H 2 6.0mm, H 3 9.0mm, H 4 12.0mm. When the target thickness is 4.5mm, and the steel grade is SDC01, the temperature data sampling of the head of the intermediate billet needs to be sampled when the finish rolling setting calculation is performed.

[0041] The target thickness of the product is 4.5mm, which is greater than the thickness threshold H 1 , and less than the thickness critical value H 2 , calculate the data sampling delay length L=L 2 , that is, 1.2m, the start position of the data sampling window is 1.2m at the head, and the end position is L+L scan = 2.3m, that is, the data sampling window is the area between 1.2m and 2.3m at the head of the middle billet of the rolled piece. The data sampling period is sampling once every 0.1 meters, and a total of 12 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com