SCM-9 molecular sieve and preparation method thereof

A technology of SCM-9 and molecular sieves, applied in molecular sieves and base exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems that have not yet been discovered, and achieve thermal stability, good stability, and good hydrothermal stability of the skeleton structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Synthesis of SCM-9 Molecular Sieve

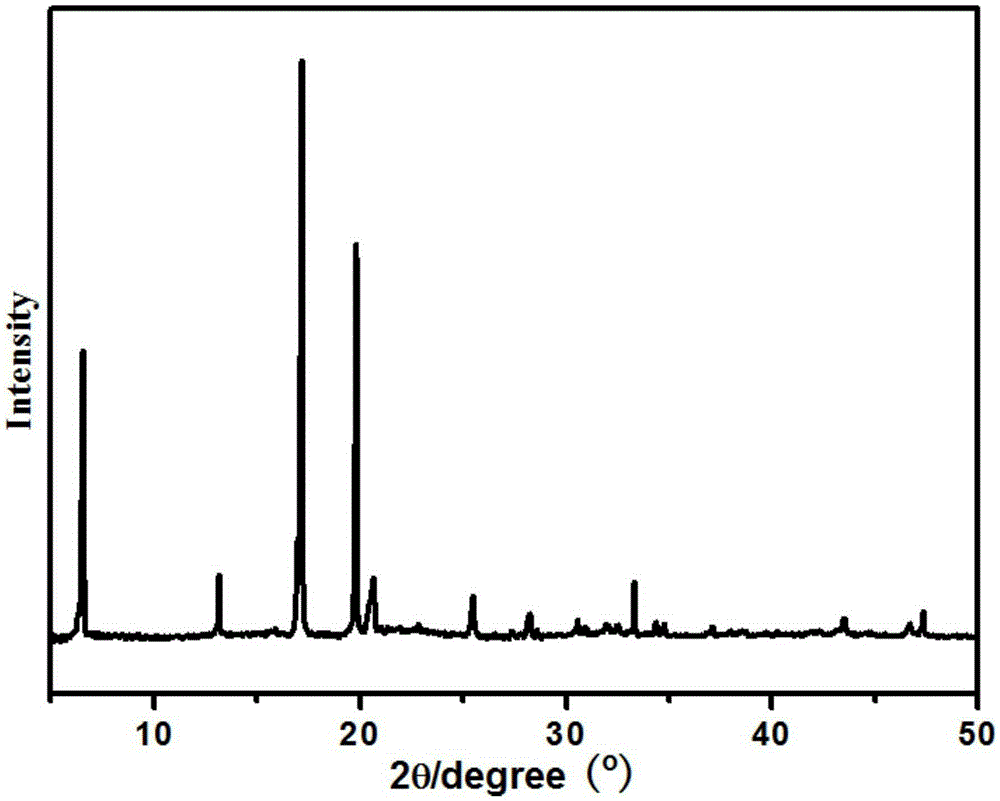

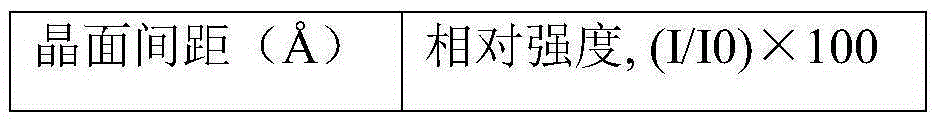

[0033] 205.63g of aluminum nitrate [Al(NO 3 ) 3 9H 2 O] was dissolved in 410.36mL of water, mixed to make solution S, and then 1547.47g of acidic silica sol (SiO 2 ,40wt.%), 91.61g sodium hydroxide (NaOH), 1.7% NaCl, 257.1g tetraethylammonium hydroxide (TEAOH, 25wt%) and 136.06g amantadine (TMAdaOH, purity ≥ 98wt.%) into S, stirred for 0.5h, and precipitated for 3 hours to obtain solution S'; put solution S' at 80°C for hydrothermal treatment for 15h, and added mineralizer hydrofluoric acid (HF, 40wt %, the feeding amount is 0.3% of the total weight of the material) and stirred for 12 hours; put the above-mentioned stirred mixture at 150°C for 15 days to crystallize, and the product was filtered and washed, then dried at 110°C for 5 hours, then heated to 400°C, and roasted at a constant temperature for 12 hours The specific material ratio of the obtained product and the reactant is listed in Table 1, and its X-ray diffraction lin...

Embodiment 2

[0037] Synthesis of SCM-9 Molecular Sieve

[0038] 321.88g of aluminum sulfate [Al 2 (SO 4 ) 3 18H 2 O, purity ≥ 98wt.%] was dissolved in 189.48mL of water, mixed to make solution S, 492.55g acidic silica sol (40wt.%), 21.25g sodium hydroxide (NaOH), accounting for 4.1% of the total weight of the reaction mass KCl And 239.57g of amantadine (TMAdaOH, purity ≥ 98wt.%) was put into S, stirred for 20h to obtain solution S'; solution S' was placed in 90°C for hydrothermal treatment for 10h, and mineralizer hydrofluoric acid (hydrofluoric acid) was added at 110°C HF, 40wt.%, the feeding amount is 1.8% of the total weight of the material) and stirred for 24 hours; the above-mentioned stirred mixture was placed at 200°C for 10 hours of crystallization, and the product was filtered and washed, then dried at 80°C for 8 hours, and then heated to 550°C. The obtained product was roasted at constant temperature for 9 hours. The specific material ratio of the reactants is listed in Table...

Embodiment 3

[0042] Synthesis of SCM-9 Molecular Sieve

[0043] 1189.16g of aluminum nitrate [Al(NO 3 ) 3 9H 2 O] be dissolved in 2549.3mL water, mix and make solution S, then 100.13g acidic silica sol (40wt.%), 224.91g sodium hydroxide (NaOH), account for the NaCl and MgCl of 3.5% of reaction mass gross weight 2 2H 2 O, 553.74g amantadine (TMAdaOH, purity ≥ 98wt.%) and 272.55g triethylamine (TEA) were put into S, stirred for 15h to obtain solution S', and the solution S' was hydrothermally treated at 120°C for 0.5h, and Add mineralizer amine fluoride (NH 4 F, the feeding amount is 3.1% of the total weight of the material) and stirred for 12 hours; put the above stirred mixture at 155°C for crystallization for 9 days, the product was filtered and washed, dried at 80°C for 9 hours, then heated to 650°C, and roasted at a constant temperature for 9 hours. The specific material ratio of the product reactants is listed in Table 1, and its X-ray diffraction lines are shown in Table 4.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com