Two-freedom-degree concentric-rotating hole-lapping device of ultrahigh back-pressure glass ball

A technology of glass balls and degrees of freedom, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of no ultra-high back pressure glass balls, difficult to guarantee accuracy, low work efficiency, etc., to ensure the precision of grinding holes and The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

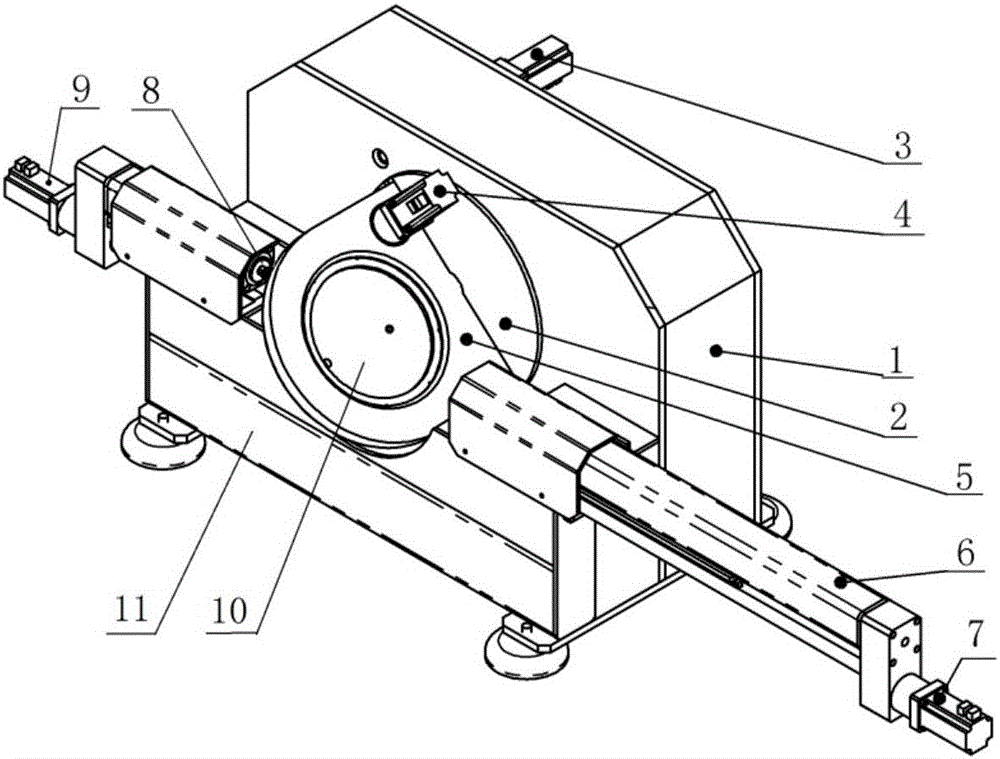

[0025] Embodiment 1: as attached figure 1 As shown, the Z-axis rotary table 2 is vertically installed on the frame 1, the X-axis rotary seat 5 is vertically installed on the outer surface y of the Z-axis rotary table 2, and the hemispherical mounting plate 10 is installed in the X-axis rotary seat 5. Axial and oppositely install inner drilling mechanism 6 and outer drilling mechanism 8, drill bits are installed on inner drilling mechanism 6 and outer drilling mechanism 8, and X-axis rotary seat 5 is in inner drilling mechanism 6 and outer drilling mechanism 8 Between, at the same time, the midline plane of the X-axis rotary seat 5 vertically passes through the diameter extension line of the Z-axis rotary disk 2, and the central axis of the inner drilling mechanism 6 and the outer drilling mechanism 8 passes through the center of the hemispherical mounting plate 10.

[0026] In the above, the Z-axis rotary servo motor 3 is installed on the frame 1, and the reduction transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com