Preparation and application methods of transition-metal-supported tungsten-base catalyst

A transition metal and catalyst technology, which is applied in the field of new tungsten-based supported catalysts to degrade cellulose, can solve the problems of complex catalyst preparation process, unsuitable for scale-up production, cumbersome process, etc., to alleviate economic crisis, facilitate large-scale production, and source raw materials wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] WO 3 Catalyst preparation: first dilute 7ml of concentrated nitric acid with a concentration of 65% into 40mL of dilute nitric acid with a concentration of 10%; then dissolve 2g of sodium tungstate dihydrate in 20mL of distilled water and add it to the dilute nitric acid solution, stir magnetically for 30min, and then load In a polytetrafluoroethylene hydrothermal kettle, react at 180°C for 3h; finally cool to room temperature, wash with ethanol and distilled water several times, and vacuum dry at 80°C for 6h. The catalyst obtained is tungsten trioxide nanosheet, expressed as WO 3 .

Embodiment 2

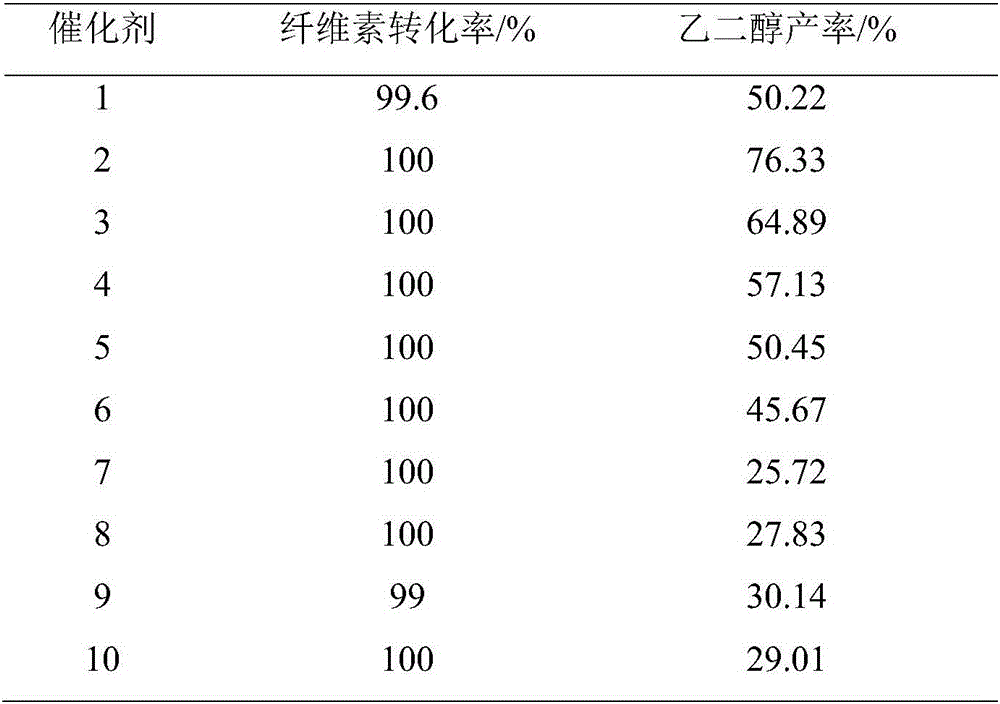

[0025] Ru / WO 3 Catalyst preparation: first, 1g WO 3 Dissolve in 25mL of distilled water, sonicate for 10min; then add 5mL of ruthenium trichloride standard solution (0.41g / 100mL) under the condition of magnetic stirring; finally wash with ethanol and distilled water several times, and vacuum dry at 80°C for 12h, the obtained catalyst contains ruthenium 1wt.%, expressed as 1%Ru / WO 3 .

[0026] Other conditions remain the same, only changing the amount of ruthenium trichloride standard solution, can get tungsten trioxide catalysts containing ruthenium with different components, respectively 0.5%Ru / WO 3 , 1%Ru / WO 3 , 2%Ru / WO 3 , 3%Ru / WO 3 , 10%Ru / WO 3 , 30%Ru / WO 3 .

Embodiment 3

[0028] Ir / WO 3 , Rh / WO 3 , Pt / WO 3 , Pd / WO 3 Preparation of the catalyst: the preparation process is similar to that of Example 2, the difference being that the ruthenium trichloride was replaced with iridium trichloride, sodium chlororhodate, sodium hexachloroplatinate, and sodium chloropalladate before the preparation. The mass content of Ir, Rh, Pt, and Pd in the catalyst is 1wt.%, which is respectively recorded as 1%Ir / WO 3 , 1%Rh / WO 3 , 1%Pt / WO 3 , 1%Pd / WO 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com