Easily cleaned automobile coating and preparation method thereof

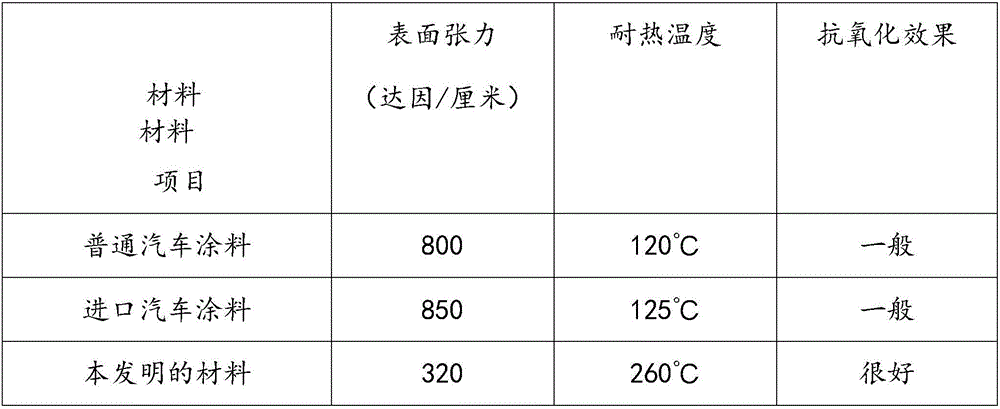

A clean and automotive technology, applied in fire-retardant coatings, coatings, etc., can solve the problems of high surface tension, poor anti-oxidation effect, and poor high-temperature resistance effect of automotive coatings, and achieves hard fading, easy cleaning, and low surface tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An easy-to-clean automotive paint, made of the following materials in parts by weight, including 75 parts of polytetrafluoroethylene, 32 parts of polyperfluoroethylene propylene, 14 parts of ethylene glycol ether, 7 parts of triethanolamine, ethyl 6 parts of glycol monomethyl ether, 12 parts of epoxy resin, 13 parts of polyamide, 5 parts of silicon dioxide, 22 parts of vinyl acetate, 15 parts of isocyanate, 7 parts of zinc chromate, 4 parts of sodium lauryl sulfate, toluene 12 parts of diisocyanate, 6 parts of methyl cellulose, 3 parts of tantalum nitride, 1 part of ammonium polyphosphate, 11 parts of zinc borate, 13 parts of methyl amyl alcohol and 13 parts of nano activated carbon.

[0019] A preparation method for an easy-to-clean automotive coating, comprising the following steps:

[0020] 1) 75 parts of polytetrafluoroethylene, 32 parts of polyperfluoroethylene propylene, 14 parts of ethylene glycol ether, 7 parts of triethanolamine, 6 parts of ethylene glycol mono...

Embodiment 2

[0026] An easy-to-clean automotive coating is made of the following materials in parts by weight, including 77.5 parts of polytetrafluoroethylene, 35 parts of polyperfluoroethylene propylene, 15 parts of ethylene glycol ether, 9 parts of triethanolamine, ethyl 7 parts of glycol monomethyl ether, 14 parts of epoxy resin, 15.5 parts of polyamide, 7.5 parts of silicon dioxide, 23 parts of vinyl acetate, 17.5 parts of isocyanate, 9.5 parts of zinc chromate, 6 parts of sodium lauryl sulfate, toluene 13 parts of diisocyanate, 6.5 parts of methyl cellulose, 4 parts of tantalum nitride, 2.5 parts of ammonium polyphosphate, 13 parts of zinc borate, 16 parts of methyl amyl alcohol and 14.5 parts of nano activated carbon.

[0027] A preparation method for an easy-to-clean automotive coating, comprising the following steps:

[0028] 1) 77.5 parts of polytetrafluoroethylene, 35 parts of polyperfluoroethylene propylene, 15 parts of ethylene glycol ether, 9 parts of triethanolamine, 7 parts ...

Embodiment 3

[0034] An easy-to-clean automotive coating is made of the following materials in parts by weight, including 80 parts of polytetrafluoroethylene, 38 parts of polyperfluoroethylene propylene, 16 parts of ethylene glycol ether, 11 parts of triethanolamine, ethyl 8 parts of glycol monomethyl ether, 16 parts of epoxy resin, 18 parts of polyamide, 10 parts of silicon dioxide, 24 parts of vinyl acetate, 20 parts of isocyanate, 12 parts of zinc chromate, 8 parts of sodium lauryl sulfate, toluene 14 parts of diisocyanate, 7 parts of methyl cellulose, 5 parts of tantalum nitride, 4 parts of ammonium polyphosphate, 15 parts of zinc borate, 19 parts of methyl amyl alcohol and 16 parts of nano activated carbon.

[0035] A preparation method for an easy-to-clean automotive coating, comprising the following steps:

[0036] 1) 80 parts of polytetrafluoroethylene, 38 parts of polyperfluoroethylene propylene, 16 parts of ethylene glycol ether, 11 parts of triethanolamine, 8 parts of ethylene gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com