Casting mold three-dimensional printing formation method

A three-dimensional, spray printing technology, applied in the direction of casting mold composition, casting mold, casting molding equipment, etc., can solve the problems of increasing and easily clogging the mold gas volume of the nozzle, so as to reduce the cost of use, improve the stability of the process, improve the The effect of curing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

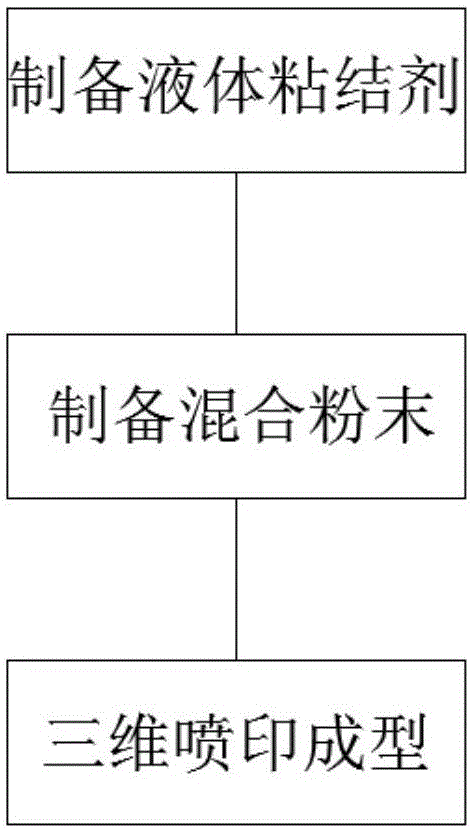

[0024] A method for forming a three-dimensional jet printing mold, comprising the following steps:

[0025] (1) In terms of parts by mass, 99.5 parts of deionized water are used as a binder, and 0.5 parts of polyols are added to the deionized water to form a mixed solution, which is used as a liquid binder material for three-dimensional jet printing;

[0026] (2) In terms of parts by mass, use 1 part of instant sodium silicate as solid binder powder and 99 parts of raw sand (the raw sand can be quartz sand, pearl sand, mullite sand or zircon sand) for mechanical mixing , the above mixed powder is used as a printing material for three-dimensional jet printing;

[0027] (3) Put the liquid binder prepared in step (1) into the inkjet print head of the rapid prototyping device, put the mixed powder prepared in step (2) into the powder tank, and turn on the rapid prototyping device for three-dimensional jet printing. During the printing process or after the part is printed, the ins...

Embodiment 2

[0030] A method for forming a three-dimensional jet printing mold, comprising the following steps:

[0031] (1) In terms of parts by mass, 70 parts of deionized water are used as a binder, and 22 parts of absolute ethanol, 3 parts of polyols and 5 parts of cetyltrimethylammonium bromide are added to the deionized water to form a mixture Solution, the above mixed solution is used as a liquid binder material for three-dimensional jet printing;

[0032] (2) In terms of parts by mass, adopt 5 parts of instant sodium silicate as solid binder powder, add 0.5 part of polyvinyl alcohol to instant sodium silicate, and then mix with 94.5 parts of raw sand (the raw sand can be quartz sand) , orb sand, mullite sand or zircon sand) are mechanically mixed, and the above-mentioned mixed powder is used as a printing material for three-dimensional jet printing;

[0033] (3) Put the liquid binder prepared in step (1) into the inkjet print head of the rapid prototyping device, put the mixed pow...

Embodiment 3

[0036] A method for forming a three-dimensional jet printing mold, comprising the following steps:

[0037] (1) In terms of parts by mass, 50 parts of deionized water is used as a binder, and 49 parts of acetone, 0.5 part of organic ester and 0.5 part of glycerin are added to deionized water to form a mixed solution. liquid binder material;

[0038] (2) In terms of parts by mass, adopt 7 parts of instant sodium silicate as solid binder powder, add 0.8 part of polyvinyl alcohol to instant sodium silicate, and then mix with 92.2 parts of raw sand (the raw sand can be quartz sand) , orb sand, mullite sand or zircon sand) are mechanically mixed, and the above-mentioned mixed powder is used as a printing material for three-dimensional jet printing;

[0039] (3) Put the liquid binder prepared in step (1) into the inkjet print head of the rapid prototyping device, put the mixed powder prepared in step (2) into the powder tank, and turn on the rapid prototyping device for three-dimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Gas output | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com