Porous hydroxyapatite bone repairing material and preparation method thereof

A hydroxyapatite bone and repair material technology, applied in medical science, prosthesis, etc., can solve the problems of collagen being easily digested by protease and poor material toughness, achieve good water solubility and biocompatibility, and improve toughness performance , the effect of enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

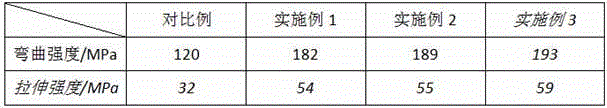

Examples

Embodiment 1

[0026] A porous hydroxyapatite bone repair material, the composition of the bone repair material includes by weight: 10 parts of hydroxyapatite, 2.5 parts of collagen, 16 parts of chitosan, 0.5 parts of polyvinyl alcohol, polyethylene glycol 2 parts of diol, the collagen is type I active collagen.

[0027] A method for preparing a porous hydroxyapatite bone repair material, comprising the following specific steps:

[0028] (1) Dissolve chitosan and collagen in an acetic acid solution with a volume fraction of 1%, and dissolve polyvinyl alcohol and polyethylene glycol in a malonic acid solution with a volume fraction of 0.3%;

[0029] (2) Slowly add the acetic acid solution of chitosan and the acetic acid solution of collagen to the malonic acid solution of polyvinyl alcohol / polyethylene glycol, stir for 2 hours, and mix them well to obtain collagen / chitosan / polyvinyl alcohol / polyethylene glycol solution;

[0030] (3) Under vigorous stirring, add 2 mol / L calcium nitrate solu...

Embodiment 2

[0037] A porous hydroxyapatite bone repair material, the composition of the bone repair material includes by weight: 15 parts of hydroxyapatite, 4 parts of collagen, 18 parts of chitosan, 1 part of polyvinyl alcohol, polyethylene 4 parts of diol, the collagen is type I active collagen.

[0038] A method for preparing a porous hydroxyapatite bone repair material, comprising the following specific steps:

[0039] (1) Dissolve chitosan and collagen in an acetic acid solution with a volume fraction of 1.5%, and dissolve polyvinyl alcohol and polyethylene glycol in a malonic acid solution with a volume fraction of 0.4%;

[0040] (2) Slowly add the acetic acid solution of chitosan and the acetic acid solution of collagen to the malonic acid solution of polyvinyl alcohol / polyethylene glycol, stir for 2.5 hours, and mix them well to obtain collagen / chitosan Sugar / polyvinyl alcohol / polyethylene glycol solution;

[0041] (3) Under vigorous stirring, add 2.5 mol / L calcium nitrate solutio...

Embodiment 3

[0048] A porous hydroxyapatite bone repair material, the composition of the bone repair material includes by weight: 20 parts of hydroxyapatite, 5 parts of collagen, 20 parts of chitosan, 1.5 parts of polyvinyl alcohol, polyethylene 6 parts of diol, the collagen is type I active collagen.

[0049] A method for preparing a porous hydroxyapatite bone repair material, comprising the following specific steps:

[0050] (1) Dissolve chitosan and collagen in an acetic acid solution with a volume fraction of 2%, and dissolve polyvinyl alcohol and polyethylene glycol in a malonic acid solution with a volume fraction of 0.5%;

[0051] (2) Slowly add the acetic acid solution of chitosan and the acetic acid solution of collagen to the malonic acid solution of polyvinyl alcohol / polyethylene glycol, stir for 3 hours, and mix them well to obtain collagen / chitosan / polyvinyl alcohol / polyethylene glycol solution;

[0052] (3) Under vigorous stirring, add 3 mol / L calcium nitrate solution and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com