Water-soluble carbon monoxide releasing molecule and preparation method and application thereof

A carbon monoxide, water-soluble technology, applied in chemical instruments and methods, botanical equipment and methods, applications, etc., to achieve excellent water solubility and biocompatibility, excellent controllable slow-release carbon monoxide performance, and broad-spectrum bactericidal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

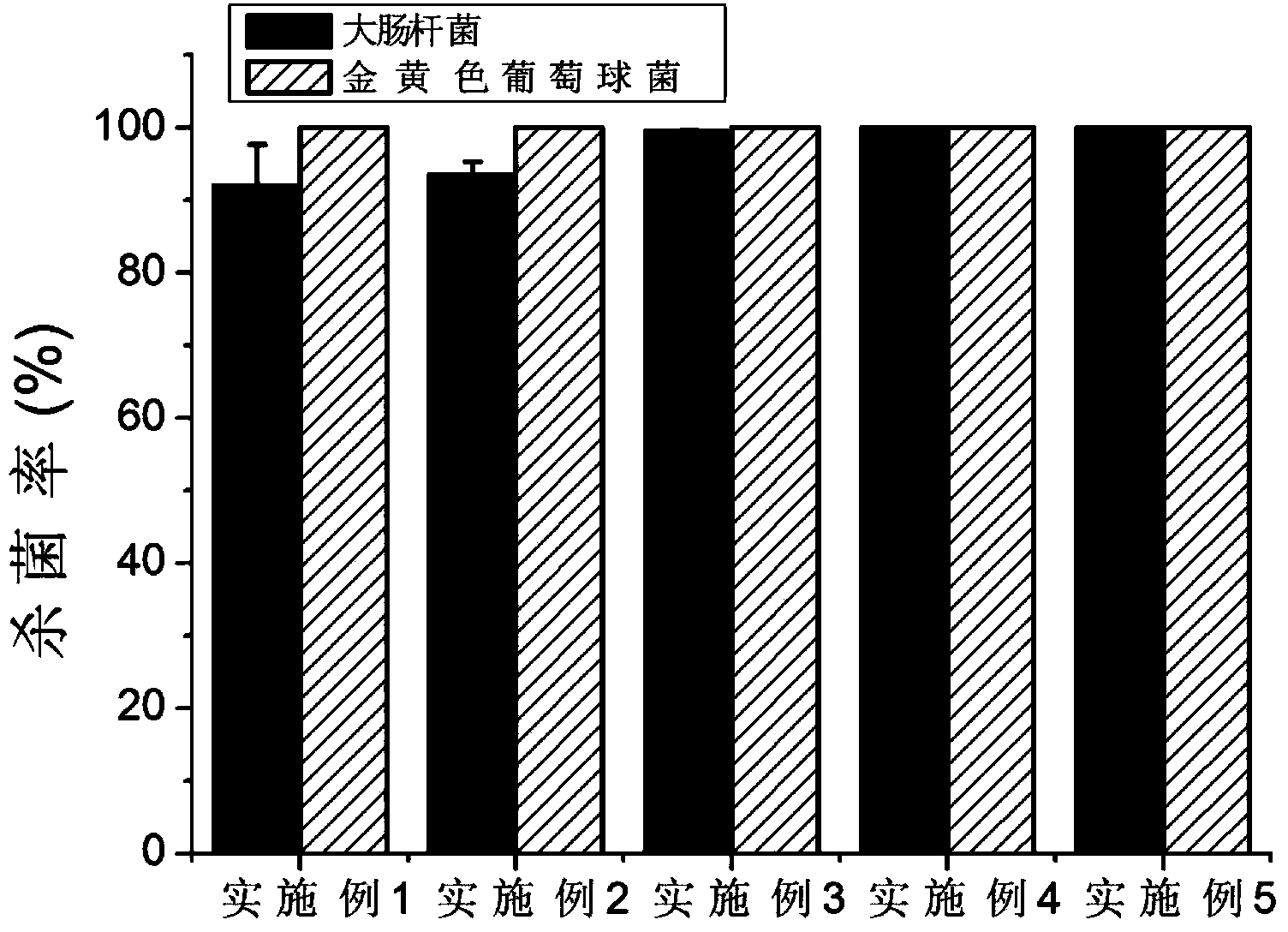

Embodiment 1

[0031] Taking the preparation of the following water-soluble carbon monoxide releasing molecule as an example, the raw materials used and the preparation method are as follows:

[0032]

[0033] 1. Preparation of Formula II Compound

[0034] Under the protection of nitrogen, add 0.532g (2mmol) molybdenum hexacarbonyl and 4mL tetrahydrofuran into the Shrek reaction tube, and then add 1.5mL1.6mol / L methyl lithium ether solution, the molar ratio of molybdenum hexacarbonyl to methyl lithium is 1:1, stirred, and placed in a dry ice-acetone bath at -78°C for 60 minutes to prepare the compound of the following formula.

[0035]

[0036] 2. Preparation of water-soluble carbon monoxide releasing molecules

[0037] Add 0.84g (4mmol) tetraethylammonium bromide to the compound prepared in step 1, stir for 1 minute, distill off tetrahydrofuran under reduced pressure at room temperature, separate the product with a silica gel column at -78°C, and use dichloromethane / petroleum ether ...

Embodiment 2

[0044] Taking the preparation of the following water-soluble carbon monoxide releasing molecule as an example, the raw materials used and the preparation method are as follows:

[0045]

[0046] In the preparation of the water-soluble carbon monoxide release molecule step 2 in Example 1, the tetraethylammonium bromide used is replaced with equimolar tetramethylammonium chloride, and the other steps are the same as in Example 1 to prepare a water-soluble carbon monoxide release molecule, Its yield was 38%.

Embodiment 3

[0048]Taking the preparation of the following water-soluble carbon monoxide releasing molecule as an example, the raw materials used and the preparation method are as follows:

[0049]

[0050] In the step 2 of preparing the water-soluble carbon monoxide release molecule in Example 1, the tetraethylammonium bromide used is replaced with equimolar tetrabutylammonium bromide, and the other steps are the same as in Example 1 to prepare a water-soluble carbon monoxide release molecule. Its yield was 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com