Composition for forming coating layer having self-healing property, coating layer, and film

A composition and performance technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve permanent damage to coatings, mechanical properties of coatings such as hardness, wear resistance or insufficient coating strength, loss of self-healing properties, etc. problem, to achieve the effect of excellent mechanical properties and excellent self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

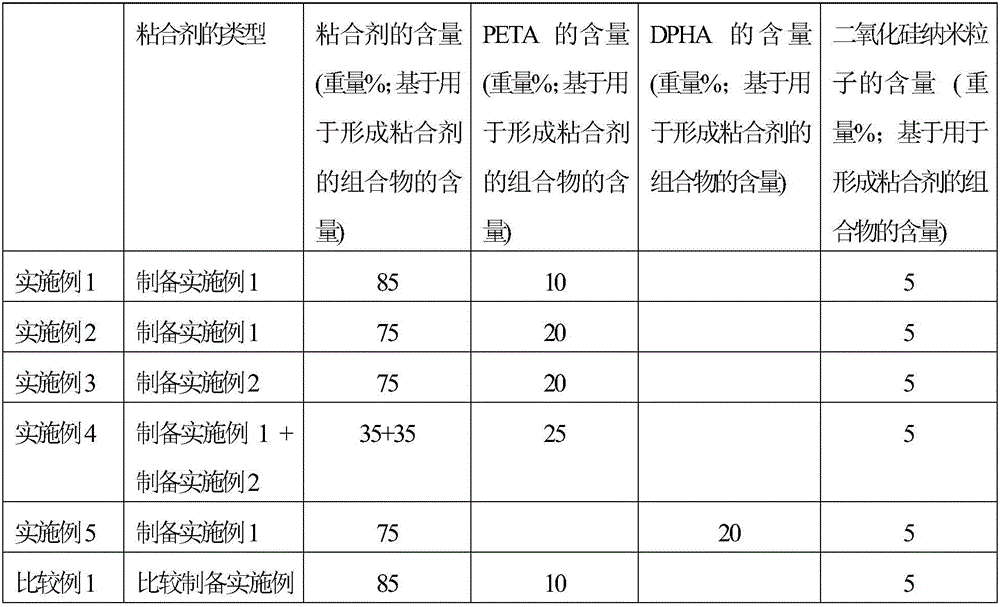

[0071] Preparation Example 1: Preparation of Polyethylene Glycol Modified Multifunctional Urethane (Meth) Acrylic Adhesive

[0072] HDI-based trimer DN980S produced by Aekyung Chemical was used as a trifunctional or higher polyvalent isocyanate-based compound, and polyethylene glycols having different number-average molecular weights by including polyethylene glycol repeating units with different repeating numbers were used respectively Monoacrylate (Mn=300) and polyethylene glycol monoacrylate (Mn=500) were used as polyethylene glycol-modified (meth)acrylate compounds.

[0073] 40g of polyvalent isocyanate compounds, 30g of polyethylene glycol monoacrylate (Mn=300) and 30g of polyethylene glycol monoacrylate (Mn=500) and 0.1g of DBTDL (dibutyltin dilaurate) It was mixed with 200 g of methyl ethyl ketone, and the mixture was stirred at 60° C. for about 5 hours to perform a urethanization reaction.

[0074] By completing the urethanization reaction, the polyethylene glycol-mod...

preparation Embodiment 2

[0075] Preparation Example 2: Preparation of Polypropylene Glycol Modified Multifunctional Urethane (Meth) Acrylic Adhesive

[0076] HDI-based trimer DN980S produced by Aekyung Chemical was used as a polyvalent isocyanate-based compound with more than three functions, and polypropylene glycol monoacrylates having different number-average molecular weights ( Mn=400) and polypropylene glycol monoacrylate (Mn=600) as polypropylene glycol-modified (meth)acrylate compounds.

[0077] 40g of polyvalent isocyanate compound, 40g of polypropylene glycol monoacrylate (Mn=400) and 40g of polypropylene glycol monoacrylate (Mn=600) with 0.15g of DBTDL (dibutyltin dilaurate) and 300g of methyl Ethyl ketone was mixed, and the mixture was stirred at 60° C. for about 5 hours to perform urethanization reaction.

[0078] By completing the urethanization reaction, the polypropylene glycol-modified polyfunctional urethane (meth)acrylate adhesive of Preparation Example 2 was prepared. Same as in P...

comparative preparation Embodiment 1

[0079] Comparative Preparation Example 1: Preparation of Polyethylene Glycol Modified Multifunctional Urethane (Meth) Acrylic Adhesive

[0080] In addition to using only 60 g of polyethylene glycol monoacrylate (Mn=500) instead of polyethylene glycol monoacrylate (Mn=300) in Preparation Example 1, the same method as in Preparation Example 1 was used. Method to prepare polyethylene glycol modified polyfunctional urethane (meth)acrylate adhesive. The progress of the urethanization reaction and the formation of the binder was confirmed by FT-IR.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| cross-linking density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com