Plastic package material through hole and filling method thereof

A technology of plastic packaging materials and filling methods, applied in the direction of electrical components, electrical solid devices, circuits, etc., to achieve the effect of avoiding too rough, good electrical interconnection effect, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a method for filling via holes of plastic encapsulants, the filling method comprising:

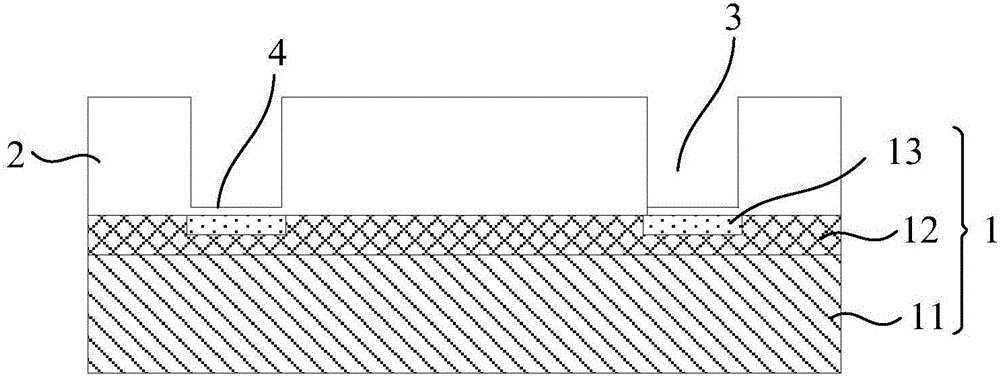

[0062] S1: providing a metal pad structure 1, and forming a plastic encapsulation material layer 2 on the upper surface of the metal pad structure 1;

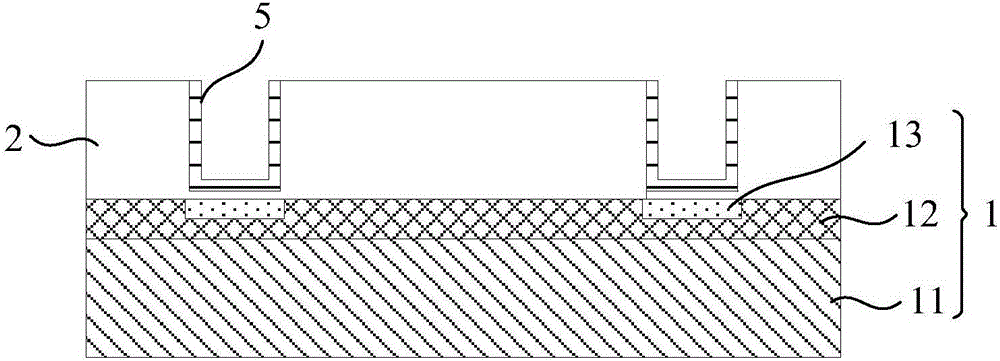

[0063] S2: Form an opening 3 on the molding material layer 2 corresponding to the position of the metal pad 13, and form a barrier layer 5 on the inner surface of the opening 3, wherein a predetermined thickness of the molding material layer remains above the metal pad 13 as protective layer 4;

[0064] S3: removing the barrier layer 5 and the protective layer 4 at the bottom of the opening 3, exposing the metal pad 13;

[0065] S4: Forming a seed layer 6 on the surface of the barrier layer 5 and the upper surface of the metal pad 13, and forming a metal layer 7 and a polymer layer 8 on the surface of the seed layer 6 in sequence.

[0066] see belowFigure 1 to Figure 4 The method for filling the via holes o...

Embodiment 2

[0096] This embodiment provides a method for filling via holes of plastic encapsulants, the filling method comprising:

[0097] S1: providing a metal pad structure 1, and forming a plastic encapsulation material layer 2 on the upper surface of the metal pad structure 1;

[0098] S2: Form an opening 3 on the molding material layer 2 corresponding to the position of the metal pad 13, and form a barrier layer 5 on the inner surface of the opening 3, wherein a predetermined thickness of the molding material layer remains above the metal pad 13 as protective layer 4;

[0099] S3: removing the barrier layer 5 and the protective layer 4 at the bottom of the opening 3, exposing the metal pad 13;

[0100] S4: Forming a seed layer 6 on the surface of the barrier layer 5 and the upper surface of the metal pad 13, and forming a metal layer 7 and a polymer layer 8 on the surface of the seed layer 6 in sequence.

[0101] see below Figure 5 to Figure 9 The method for filling the via hole...

Embodiment 3

[0137] Such as Figure 4 with Figure 9 As shown, this embodiment provides a via hole for molding compound, and the via hole for molding compound includes:

[0138] Metal pad structure 1;

[0139] A plastic encapsulant layer 2 located on the upper surface of the metal pad structure 1 and formed with a via hole at a position corresponding to the metal pad 13;

[0140] The barrier layer 5 located on the inner wall surface of the via hole;

[0141] a seed layer 6 located on the surface of the barrier layer 5 and the upper surface of the metal pad 13;

[0142] a metal layer 7 on the surface of the seed layer 6; and

[0143] A polymer layer 8 located on the surface of the metal layer 7 and filling the via hole.

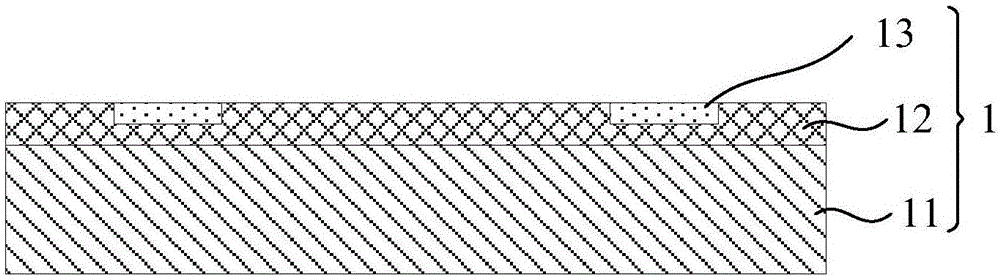

[0144] As an example, the metal pad structure 1 includes:

[0145] carrier plate 11;

[0146] a redistribution layer 12 located on the upper surface of the carrier 11; and

[0147] At least one metal pad 13 located on the redistribution layer 12 .

[0148] Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com