Laser annealing apparatus, preparation method of polycrystalline silicon thin film and preparation method of thin film transistor

A technology of polysilicon thin film and laser annealing, which is applied in laser welding equipment, transistors, lasers, etc., can solve the problems of not being suitable for large-area glass substrates, and achieve the effect of solving large leakage current, reducing non-uniformity, and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

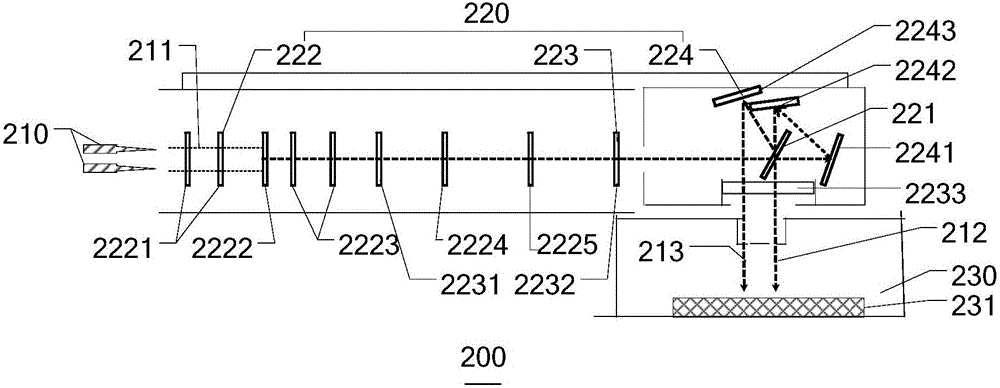

[0046] This embodiment provides a kind of laser annealing equipment, for example, image 3 A structural schematic diagram of a laser annealing device provided for an embodiment of the present invention, the laser annealing device 200 includes: a laser generator 210, an optical path element 220 and an annealing chamber 230, the laser generator 210 is configured to emit a laser beam 211, and the laser beam 211 is guided to the annealing chamber 230 through the optical path element 220; the optical path element 220 includes a beam splitter 221, and the beam splitter 221 decomposes the laser beam 211 into a first beam 212 and a second beam 213 and makes the energy density of the first beam 212 greater than The energy density of the second beam 213, the first beam 212 and the second beam 213 are directed into the annealing chamber 230 for laser annealing.

[0047] The first light beam 212 irradiates the amorphous silicon film at first so that it is annealed into a polysilicon film....

Embodiment 2

[0082] This embodiment provides a method for preparing a polysilicon film, for example, Figure 6 A flow chart of a method for preparing a polysilicon thin film provided in this embodiment, Figure 7a-7b A process diagram of a method for preparing a polysilicon thin film provided in this embodiment. The preparation of polysilicon film comprises the following steps:

[0083] S101: Provide a base substrate.

[0084] For example, after the base substrate is provided, the provided base substrate is first pre-cleaned, and then the base substrate is positioned on the carrying platform at the bottom of the annealing chamber. For example, the base substrate includes a glass substrate, a quartz substrate, or a substrate made of other suitable materials.

[0085] S102: Depositing an amorphous silicon thin film on the base substrate.

[0086] For example, before depositing the amorphous silicon thin film on the base substrate, a buffer layer thin film may also be deposited on the bas...

Embodiment 3

[0106] This embodiment provides a method for preparing a thin film transistor, including: using any one of the preparation methods in Embodiment 2 to prepare a polysilicon film; patterning the polysilicon film to form a polysilicon pattern as an active layer of the thin film transistor.

[0107] For example, Figure 9 A flow chart of a method for preparing a thin film transistor provided in this embodiment, the preparation of a thin film transistor includes the following steps:

[0108] S201: preparing a polysilicon thin film.

[0109] For example, the polysilicon film is prepared by any preparation method in Embodiment 2, for example, the height of the protrusions on the surface of the polysilicon film is less than 25% of the thickness of the polysilicon film.

[0110] S202: Patterning the polysilicon film to form a polysilicon pattern as an active layer of a thin film transistor.

[0111] For example, the patterning process includes coating photoresist on the formed polysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com