Optical processing systems and methods

A technology of optical processing and optical path direction, applied in optics, opto-mechanical equipment, microlithography exposure equipment, etc., can solve the problems of difficulty in obtaining stripe outline, influence of pattern outline, unbearable, etc., to achieve clear pattern outline and better equipment performance. Excellent, fast response and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

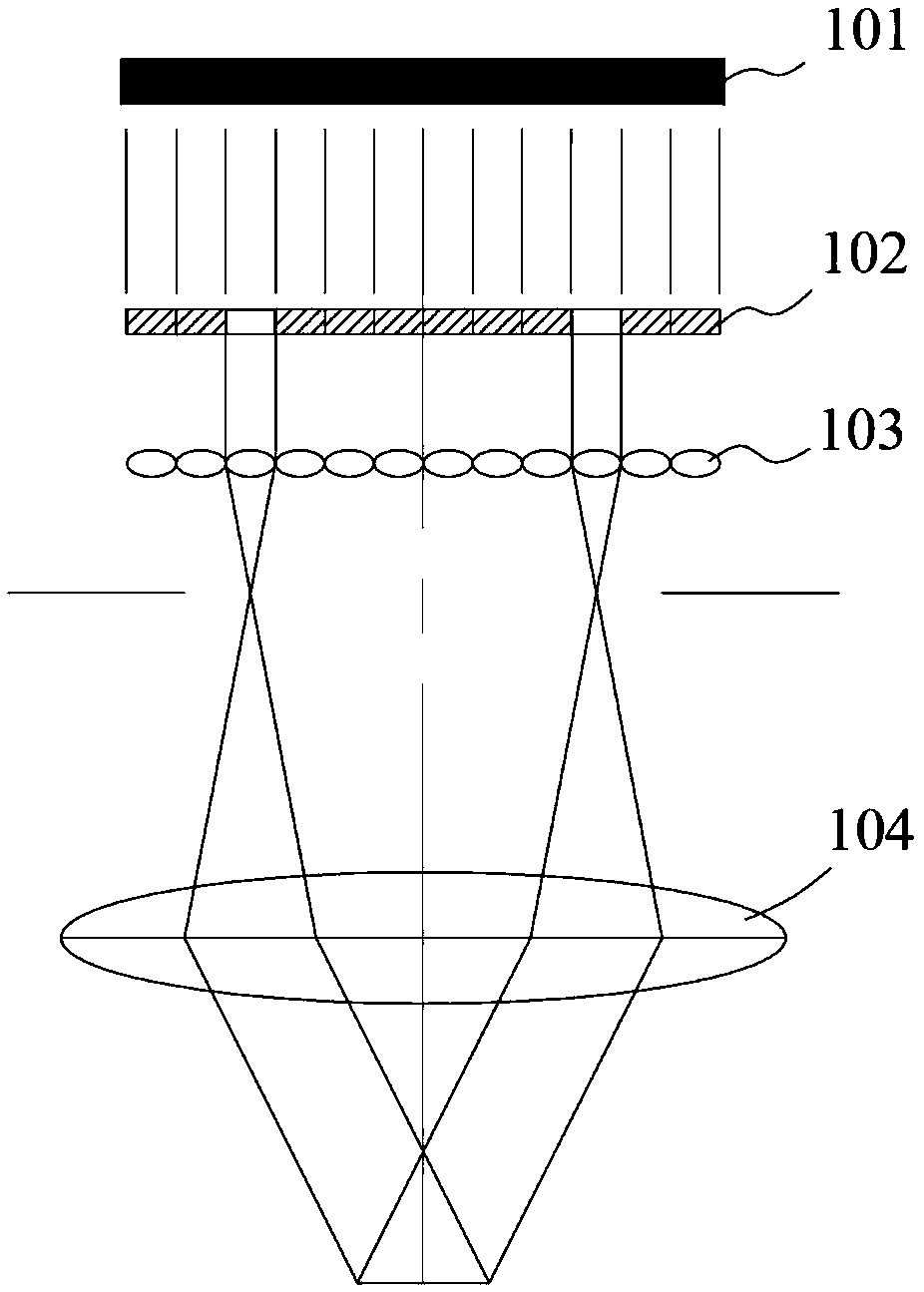

[0061] combine Figure 4 As shown, a front-stage mirror group is also provided in the direction of the optical path, and the front-stage mirror group is arranged between the spatial light modulator 102 and the microlens array 103. The front-stage mirror group includes a first lens 201 and a second lens arranged along the direction of the optical path. Two lenses 202 .

[0062] In this technical solution, the front-stage mirror group is a projection imaging optical path, which is composed of a first lens and a second lens. It has two functions: 1. The front-stage lens group projects the SLM into the front focal plane of the microlens array 103 . The precise matching of the unit size and the overall format of the SLM and the microlens array 103 can be realized through optical zooming. 2. The focal length of the microlens array 103 is very short (about a few millimeters), and the space between the optical path elements is narrow, making adjustment difficult. After adopting the...

Embodiment 2

[0074] combine Figure 5As shown, on the basis of the first embodiment, this embodiment also includes a seventh lens 301 and a switching device. In the first state, the switching device drives the front-stage lens group and the microlens array 103 as a whole 302 to move to the spatial light modulator 102 and the optical path between the imaging lens (group) 104, in the second state, the switching device drives the seventh lens 301 to move to the optical path between the spatial light modulator 102 and the imaging lens (group) 104, and simultaneously the front-stage lens group and microlens array 103 as a whole 302 out.

[0075] In this technical solution, this solution can realize the sharing of interference lithography and imaging lithography, so that one device has two functions, and can realize the precise registration of interference lithography images and imaging lithography, in printing and packaging, security It has important applications in identification and micro-na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com