Method for preparing zinc-doped iron trioxide composite structure gas-sensitive element

A technology of ferric oxide and gas sensor, which is applied in the direction of measuring devices, instruments, and material analysis through electromagnetic means, which can solve the problems of low sensitivity, long response recovery time, poor selectivity, etc., and achieve good thermal stability, Improved sensitivity and response recovery time, easy to prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] (1) Weigh 0.4973g (1.84mmol) ferric chloride hexahydrate, 0.2510g (1.84mmol) anhydrous zinc chloride and 0.3057g (1.84mmol) terephthalic acid into a beaker;

[0030] (2) Measure 80 mL of N,N-dimethylformamide into a beaker, and stir evenly at room temperature for 10 minutes;

[0031] (3) After the reactants are completely dissolved, put the obtained clear solution into the lining of a 100mL autoclave, and place it in an oven at 150°C for 2 hours;

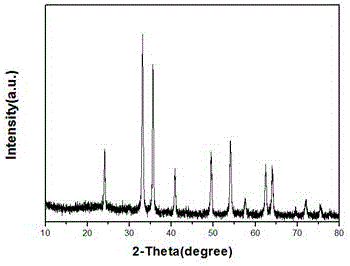

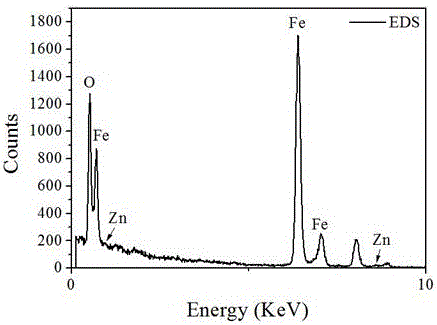

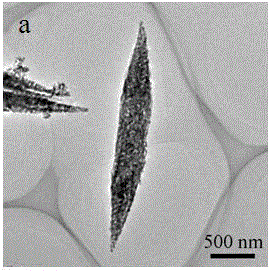

[0032] (4) After the reaction, the precipitate was centrifuged, washed and dried to obtain Zn-doped MIL-88B nano-spindle powder. Finally, the product was placed in a muffle furnace and calcined in an air atmosphere at 500 °C for 2 h, and finally Zn-doped α-Fe was obtained. 2 o 3 Nanocomposite powder;

[0033] (5) Weigh 5-10 mg of the nanocomposite powder obtained in step (4), add 1 drop of terpineol and grind it evenly, then spread it evenly on the ceramic tube, dry it naturally and place it in a muffle furnace, at 300 si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com