Double-thermal-mass coupling solar hot air type evaporating system and method thereof

A technology of coupling solar energy and evaporation system, which is applied in the field of double thermal mass coupling solar hot air evaporation system, can solve the problems of increased investment cost, low heat transfer coefficient, and impossibility of application, so as to reduce investment cost, reduce heat exchange area, The effect of improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

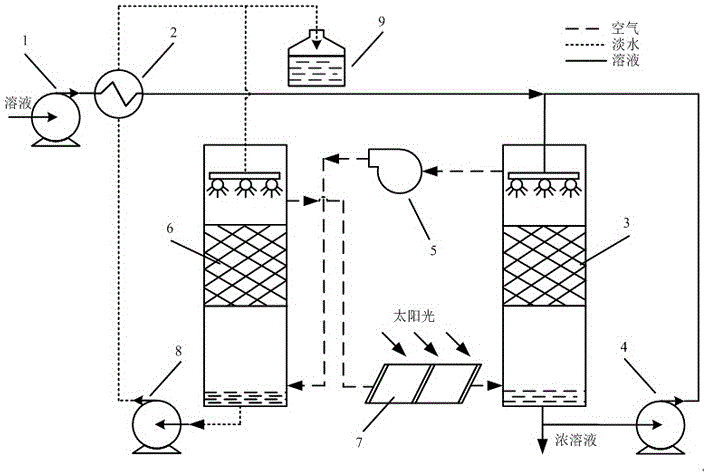

[0013] Refer below figure 1 The operation process of the dual heat mass coupled solar hot air evaporation system is described.

[0014] figure 1 It is a dual thermal mass coupled solar hot air evaporation system proposed by the present invention. The working process of the system is as follows: the salt solution is sucked by the solution pump and preheated by the waste heat recovery device. After the preheated solution is mixed with the concentrated solution pumped by the concentrated solution pump, it enters the humidifier through the solution inlet at the top of the humidifier. Humidify the air entering the air inlet at the lower end of the humidifier to become humid air, and the remaining concentrated solution is discharged through the solution outlet at the bottom of the humidifier; the humidified air enters the air inlet at the lower end of the dehumidifier through the fan, and connects with the fresh water inlet at the top of the dehumidifier The incoming water perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com