Oil and gas well cementation tubular column and well cementation method

A technology for oil and gas wells and well cementing, which is applied to wellbore/well components, wellbore/well valve devices, earthwork drilling and production, etc. It can solve problems such as inability to establish circulation, increase operational risks, and failure of cementing operations to proceed normally. , to achieve the effect of improving construction efficiency and reducing operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

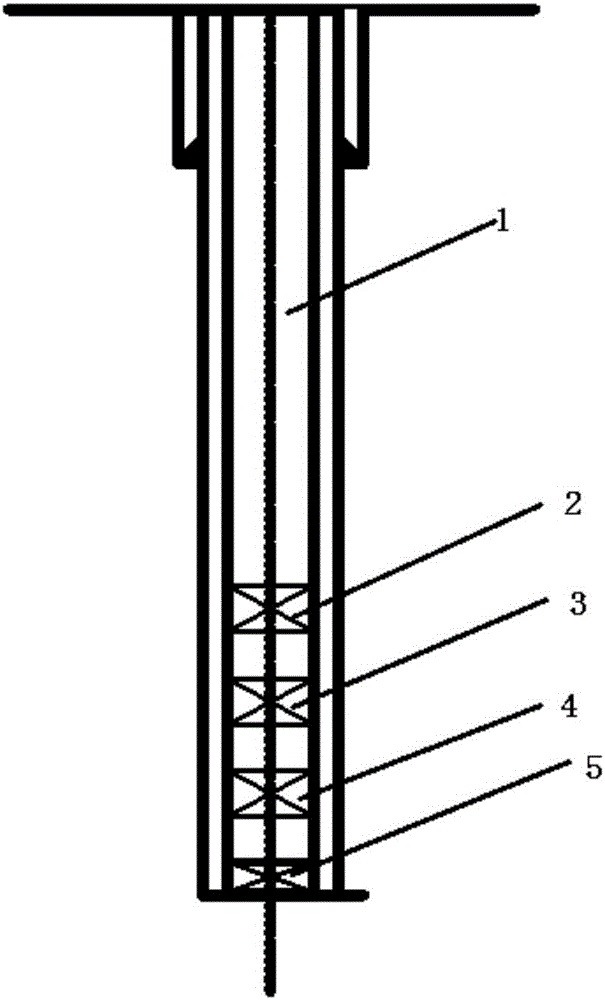

[0032] see figure 1 , the invention discloses a cementing string for an oil and gas well, which is characterized in that it includes a casing 1, and the casing 1 is sequentially provided with floating shoes 5, floating hoops 4, blasting sliding sleeves 3 and well shut-in Sliding sleeve 2, the blasting sliding sleeve 3 is provided with a bursting disc 36 and a piston 34, and the bursting disc 36 is used to push the piston 34 to move to form a fluid channel in the blasting sliding sleeve 3 for well cementing construction. The shut-in sliding sleeve 2 is provided with a self-locking device for closing the fluid channel and forming a cement plug to complete the well cementing construction.

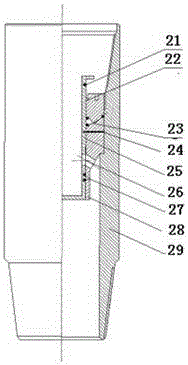

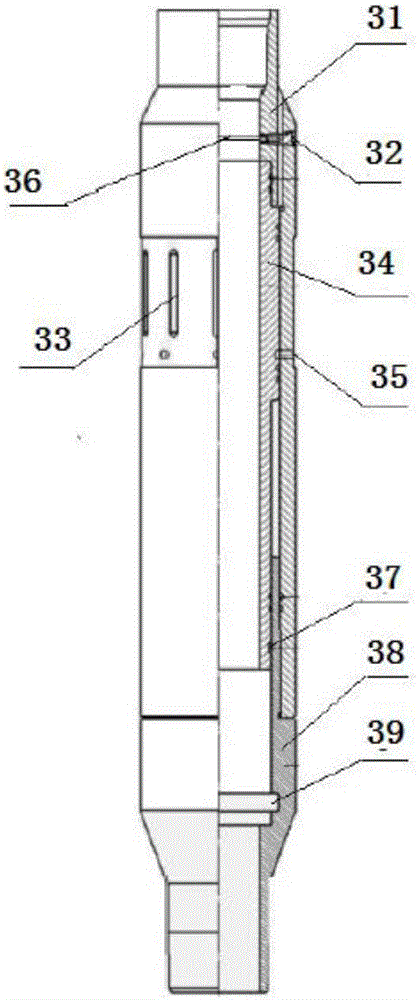

[0033] Among them, see image 3 , the blasting sliding sleeve 3 is composed of an upper joint 31 and a lower joint 38, the upper joint 31 is provided with a circulation channel 33, the burst disc 36 is provided on the upper part of the upper joint 31, and the piston 34 is provided at the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com