Growth of rare earth scintillation crystals with low cost

A scintillation crystal and rare earth technology, which is applied in the growth field of low-cost rare earth scintillation crystals, can solve the problems of high cost, long growth cycle, high labor cost and high investment, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0157] According to the above preparation process, the raw materials of rare earth scintillation crystals are first multi-stage cascade crystallized to obtain Lu with a purity higher than 99.995%. 2 o 3 , SiO 2 , CeO 2 Powder, according to Lu 2 o 3 :SiO2 2 :CeO 2 =1.08:1:0.02 Proportion weighing, fully mixed to obtain mixed raw materials (oxide raw materials).

[0158] Then design a three-stage settling tank in series, 1) put the oxide raw material into the first-stage settling tank, wash the oxide with deionized water and then settle; 3) Move the liquid in the secondary settling tank to the tertiary settling tank, then move the liquid in the primary settling tank to the secondary settling tank, and continue to inject it into the primary settling tank Deionized water was subjected to three sedimentation. Repeat the above process 4 times, and take out the cleaned oxide raw material from the bottom of the settling tank.

[0159] Then press it under 50MPa to make a raw m...

Embodiment 2

[0163] According to the above preparation process, the raw materials of rare earth scintillation crystals are first multi-stage cascade crystallized to obtain Lu with a purity higher than 99.995%. 2 o 3 , Y 2 o 3 , SiO 2 , CeO 2 Powder, according to Lu 2 o 3 :Y 2 o 3 :SiO2 2 :CeO 2 =0.83:0.16:1:0.01 Proportional weighing, fully mixed to obtain mixed raw materials (oxide raw materials).

[0164] Then design a three-stage settling tank in series, 1) put the oxide raw material into the first-stage settling tank, wash the oxide with deionized water and then settle; 3) Move the liquid in the secondary settling tank to the tertiary settling tank, then move the liquid in the primary settling tank to the secondary settling tank, and continue to inject it into the primary settling tank Deionized water was subjected to three sedimentation. Repeat the above process 3 times, and take out the cleaned oxide raw material from the bottom of the settling tank.

[0165]Then press i...

Embodiment 3

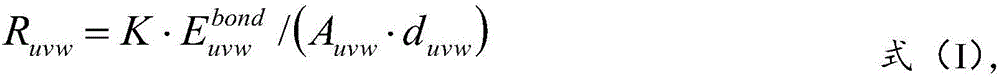

[0168] According to the above preparation process, the raw materials of rare earth scintillation crystals are first multi-stage cascade crystallized to obtain Lu with a purity higher than 99.995%. 2 o 3 , Y 2 o 3 , SiO 2 , CeO 2 Powder, according to Lu 2 o 3 :Y 2 o 3 :SiO2 2 :CeO 2 =0.83:0.16:1:0.01 Proportional weighing, fully mixed to obtain mixed raw materials (oxide raw materials). Then press it under 50MPa to make a raw material cake, put the raw material cake into a high-purity crucible and sinter at 1050°C under the protection of an inert atmosphere to form a polycrystalline material block. The dominant growth direction [001] was determined by using the chemical bonding theory of crystal growth, and the lutetium silicate single crystal with the crystal direction [001] was used as the seed crystal. Using the crystal growth theory to calculate the Ce:LYSO crystal with a diameter of 35 mm, the pulling growth rate along the [001] direction is 3.8-6.2 mm / h, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com