Loading method capable of controlling buffering type multilayer polycrystalline silicon seed crystal melting

A polysilicon and buffer layer technology, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and crystal growth, can solve problems such as uneven silicon material composition, seed crystal layer melting through, and seed crystal layer overmelting, etc., to reduce Effects of defect clusters, reduction of grain boundary formation, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

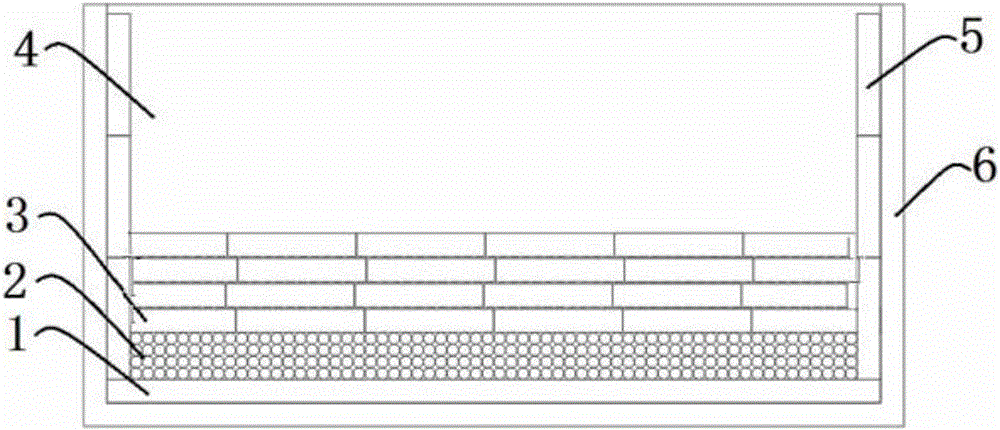

[0023] refer to figure 1 Shown, a kind of charging method of buffer type multi-layer polysilicon seed melting control, comprises the following steps:

[0024] Step a, laying a layer of polysilicon block on the bottom of the crucible 6 as the seed crystal layer 1 of the directional solidification semi-melting process, and the thickness of the seed crystal layer 1 is 12-18mm;

[0025] Step b, stacking small particles of primary polysilicon material and fine polysilicon fragments on the seed layer 1 as a buffer layer 2, the filling height of the buffer layer 2 is 100-150mm;

[0026] Step c, stacking multi-layer polysilicon bricks on the buffer layer 2 as the barrier layer 3, the length, width and height of the polysilicon bricks are 156 mm, 156 mm, and 30-40 mm respectively, and the center of the barrier layer 3 A total of 25 crystal bricks are used at the place, and each side is filled with crystal bricks; the inner wall of the crucible 6 is provided with polysilicon crystal br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com