A tubular double-ion electrolytic cell

A dual-ion, electrolytic cell technology, applied in the field of electrolytic cells, can solve the problems of increasing gas diffusion polarization potential, affecting hydrogen conversion efficiency, complex battery structure, etc., and achieves the effects of increasing anode active area, controlling hydrogen leakage, and optimizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

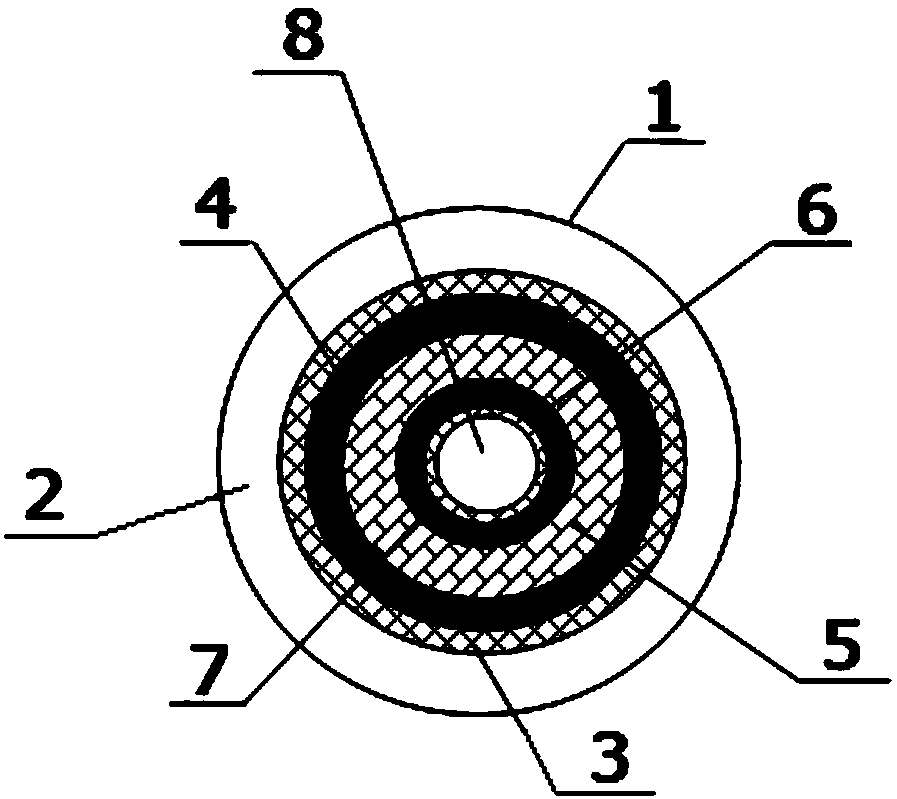

[0018] A tubular double-ion type electrolytic cell, such as figure 1 As shown, including a metal tube 1, an oxygen channel 2, a cathode 3, a cathode electrolyte layer 4, a water vapor channel 5, an anode electrolyte layer 6, an anode 7 and hydrogen channel 8, the outer shell of metal tube 1 is made of high temperature resistant metal or composite material, and its pressure resistance is 5bar; the inner shell of metal tube 1 is made of composite material, and its pressure resistance is 10 bar, and the metal tube The length of 1 is about 1m, the outer diameter of the metal tube shell (that is, the outer diameter of the entire electrolytic cell) is about 1cm, and the inner diameter of the hydrogen flow channel (that is, the inner diameter of the entire electrolytic cell) is about 0.4cm; the catholyte layer 4 is a thin film The dense YDC ceramic material, the anode electrolyte layer 6 is a thin film and dense BCY ceramic material, the thickness of the cathode electrolyte layer 4 a...

Embodiment 2

[0021] A kind of tubular double-ion type electrolytic cell, its structure is similar to a kind of tubular double-ion type electrolytic cell in embodiment 1, and its difference is:

[0022] 1. The pressure resistance of the outer shell of the metal pipe is 7.5bar, and the pressure resistance of the inner shell of the metal pipe is 15bar;

[0023] 2. The thickness of the cathode is 150 μm and the porosity is 50%; the thickness of the anode is 75 μm and the porosity is 50%; the thickness of the water vapor channel is 300 μm;

[0024] 3. The pressure control of oxygen channel, water vapor channel and hydrogen channel is 0.75 bar;

[0025] 4. Both the cathode electrolyte layer and the anode electrolyte layer have a thickness of 30 μm;

[0026] 5. Argon is used as the carrier for the gas flow in the oxygen channel, water vapor channel and hydrogen channel.

Embodiment 3

[0028] A kind of tubular double-ion type electrolytic cell, its structure is similar to a kind of tubular double-ion type electrolytic cell in embodiment 1, and its difference is:

[0029] 1. The pressure resistance of the outer shell of the metal pipe is 10bar, and the pressure resistance of the inner shell of the metal pipe is 20bar;

[0030] 2. The thickness of the cathode is 200 μm and the porosity is 60%; the thickness of the anode is 100 μm and the porosity is 60%; the thickness of the water vapor channel is 500 μm;

[0031] 3. The pressure control of oxygen channel, water vapor channel and hydrogen channel is 1.0 bar;

[0032] 4. Both the cathode electrolyte layer and the anode electrolyte layer have a thickness of 50 μm;

[0033] 5. The gas flow in the oxygen channel, water vapor channel and hydrogen channel adopts the mixed gas of nitrogen and argon as the carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com