Floating side plates for ultra-high pressure gear pumps

A floating side plate, gear pump technology, applied in pump components, machines/engines, rotary piston type/oscillating piston type pump components, etc., can solve the difficulty of forming and maintaining friction pairs, reduce the mechanical efficiency, diameter To improve the unbalanced force and other problems, to achieve the effect of enhancing the sealing effect and safety performance, improving the sealing effect of the end face, and reducing the deflection and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

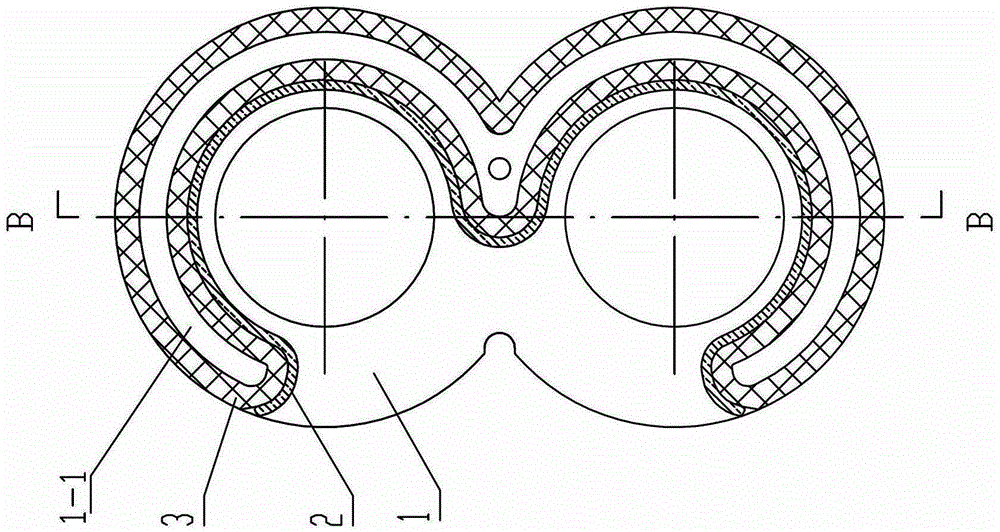

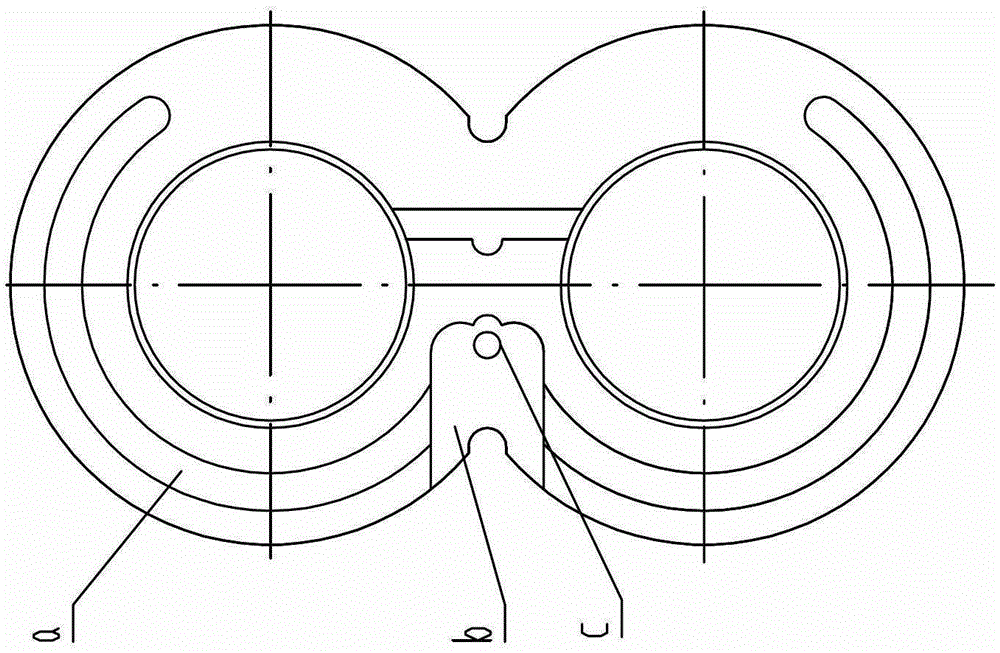

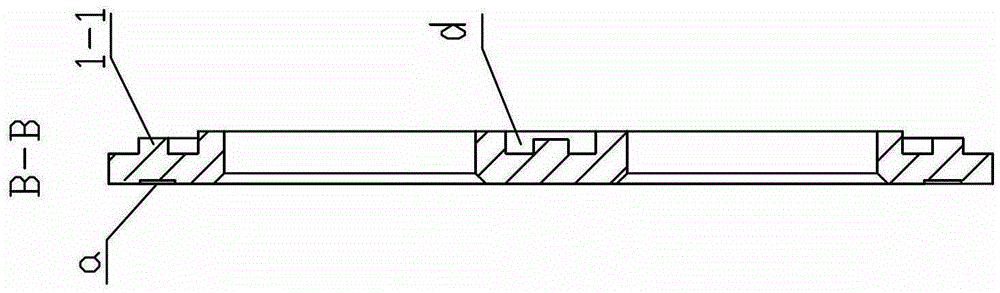

[0025] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 A floating side plate of an ultra-high pressure gear pump is shown, which includes a floating side plate 1 that matches the gears in the gear pump, and a "W"-shaped balance groove is made on the side of the floating side plate 1 close to the end face of the gear a. The unloading tank b connected with the balance tank a, the other side of the floating side plate 1 is made with a "W"-shaped sealing groove d, and there is a "W"-shaped reinforcing rib 1 in the "W"-shaped sealing groove d -1, A through hole c is made between the "W"-shaped sealing groove d and the unloading groove b, and a "W"-shaped sealing ring 3 is installed in the "W"-shaped sealing groove d, and the "W"-shaped The sealing ring 3 is integrally set on the "W"-shaped reinforcing rib 1-1, and it is characterized in tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com