Prefabricated clamping and pressing connecting assembly of assembly type gas meter box

A technology for connecting components and gas meters, applied in measuring devices, instruments, liquid/fluid solid measurement, etc., can solve the actual needs of residential gas meter assembly and provide corresponding gas meter boxes, users and gas companies are uneconomical, The unreasonable structure of the gas meter box can ensure the stability of metering, control leakage problems, and achieve significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

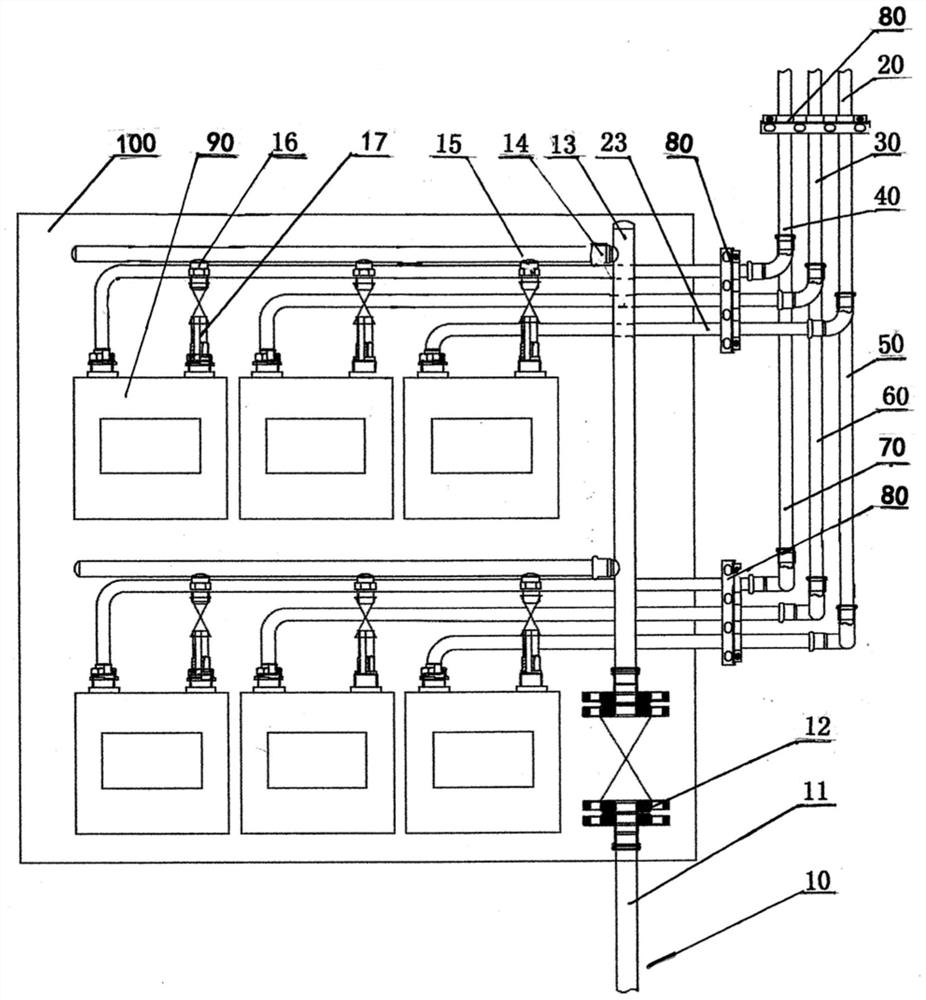

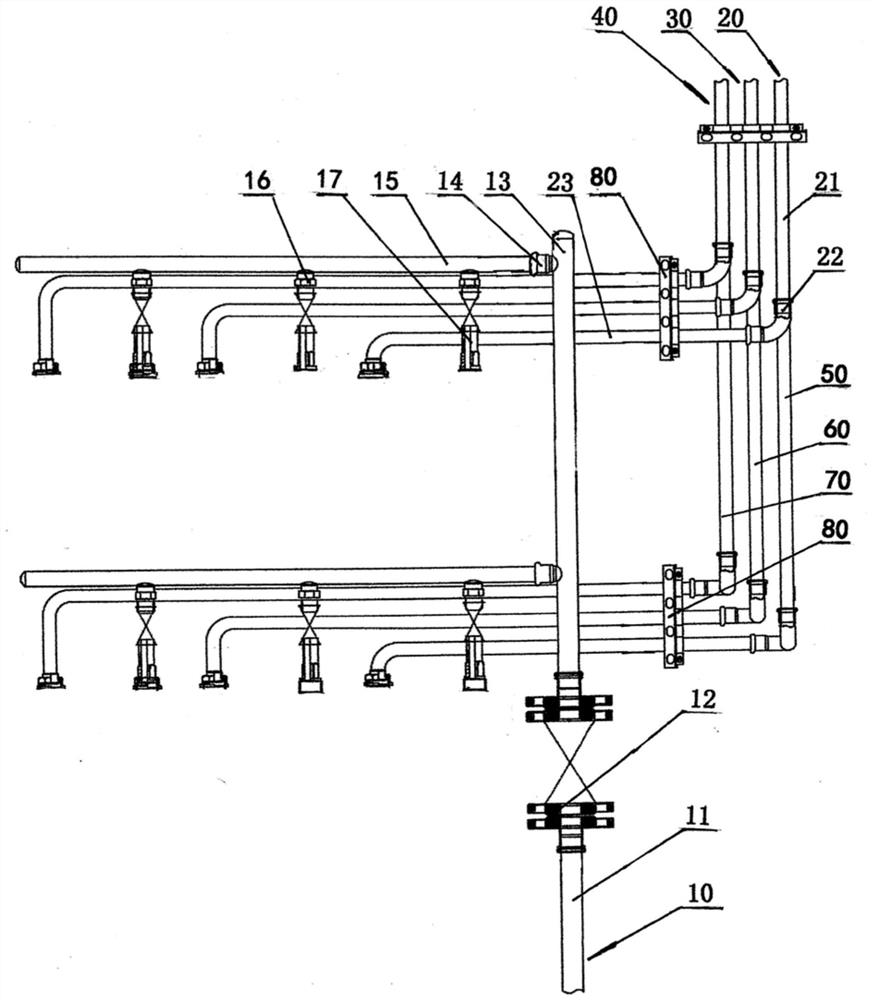

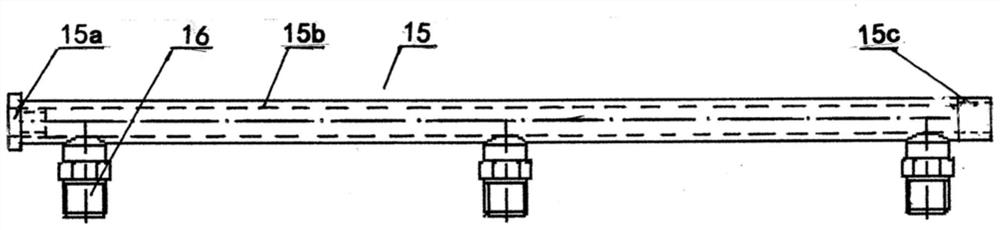

[0023] The specific implementation of a prefabricated press connection assembly for an assembled gas meter box of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 — Figure 8Shown: a prefabricated clamping connection assembly of an assembled gas meter box of the present invention, including a standard gas box body 100 planned and formulated by the gas company from two meter boxes to twelve meter boxes, pipes, pipe expansion joints 12, and pipe holders 80, characterized in that: the prefabricated clamping connection assembly of the assembled gas meter box matched with the gas meter box 100 is composed of a main gas pipeline 10, a first gas branch pipeline 20, a second gas branch pipeline 30, and a third gas branch pipeline 40 , the fourth gas branch pipeline 50, the fifth gas branch pipeline 60, the sixth gas branch pipeline 70, the pipeline holder 80, and the gas meter 90. The gas main pipeline 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com