Ruler and instrument integrated installing frame for leveling

A technology of leveling and mounting brackets, which is applied in the direction of measuring devices, height/level measuring, instruments, etc., can solve problems such as inoperability, damaged leveling rods, time-consuming and labor-intensive combined operations, etc., to solve practical operability problems and prolong service life , to ensure the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

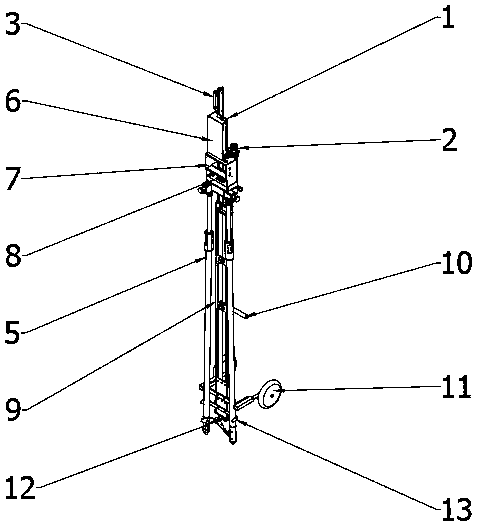

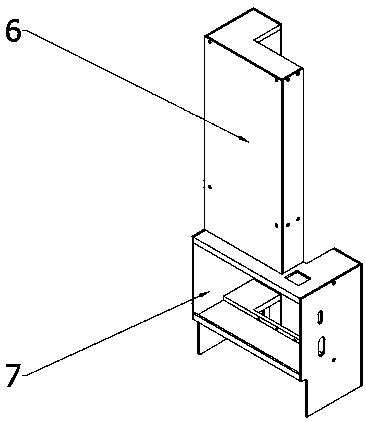

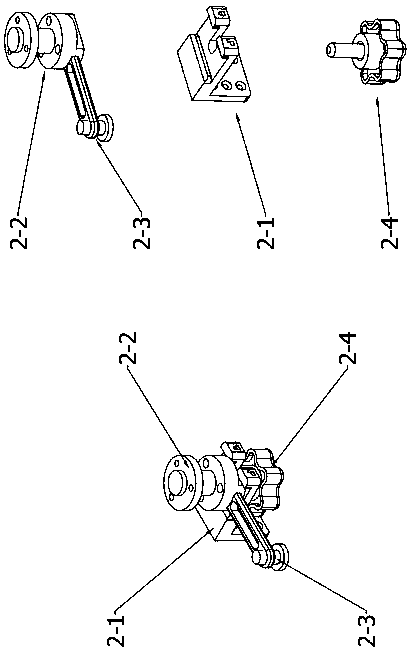

[0020] Examples of the present invention figure 1 Shown: There is a vertical long ruler base 1 made of aluminum alloy and other materials. 1 has a fixture for fixing the leveling staff. The top of the ruler base 1 is fixed with a level installation base 2 and a drag handle 3, the middle part of the ruler base 1 is rotationally connected with the auxiliary tripod 5 through a vertical rotating shaft 4, and the ruler base 1 above the rotating shaft 4 is provided with a battery compartment 6, an electronic hand The book cabin 7 and the L-shaped leveler cabin 8 are provided with a vertical handle 9 and a horizontal handle 10 on the ruler base 1 below the rotating shaft 4, and the lower part of the ruler base 1 is provided with a mobile caster 11 and a foot pad installation base 12. For the convenience of portability, a limit frame 13 for limiting the feet of the auxiliary tripod 5 can be set at the bottom of the ruler base 1 .

[0021] The shape and structure of the battery compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com