345mpa-grade vanadium-titanium microalloyed hot-rolled steel strip for anti-seismic structure and preparation method thereof

A technology of microalloying and anti-vibration structure, applied in the field of microalloying, hot continuous rolling steel strip and its production, can solve the problems of high alloy cost, poor equipment and process adaptability, undisclosed equipment conditions, etc., and achieves low alloy cost, Narrow intensity fluctuation range, high ductility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

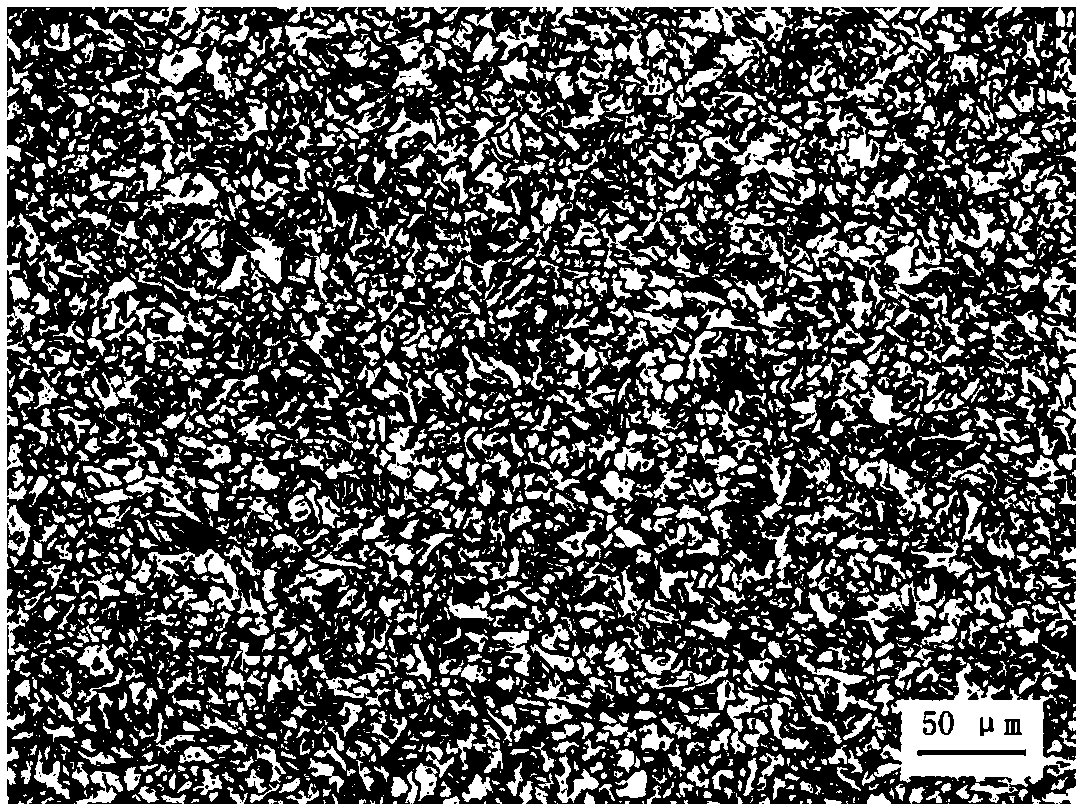

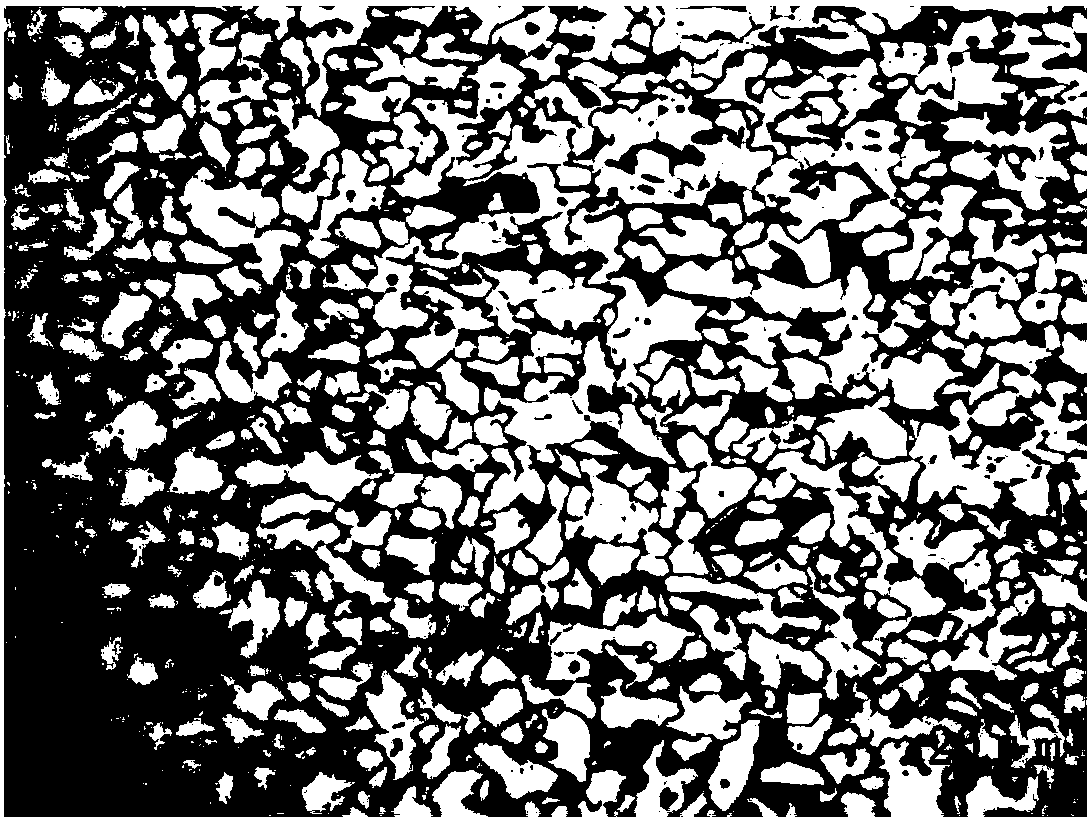

[0051] The 10.85mm thick 345MPa grade seismic structural steel adopts vanadium-titanium micro-alloying composition route, and undergoes molten iron pretreatment, converter smelting, LF heating furnace refining, and continuous casting to obtain billets. The specific chemical composition weight percentage is: 0.16%C-0.19 %Si-1.10%Mn-0.03%V-0.025%Ti-0.016%P-0.004%S; billet reheating temperature is 1245℃, reheating time is 280min; The ratio is 26%, 27%, 29%, 30%, 30%, and the thickness of the intermediate billet is 38mm; the finishing rolling is 6-stand hot continuous rolling, and the reduction ratio of each pass is 35%, 34%, 0, 27 %, 0, 11%, the finish rolling temperature is 841°C, after finish rolling, it is cooled to 600°C at a cooling rate of 16.8°C / s by means of sparse cooling.

[0052] After testing, the microstructure and properties of the 345MPa-grade seismic steel produced in this example are: Rel: 395MPa, Rm: 543MPa, A: 26.0%, Rel / Rm: 0.73, longitudinal impact energy at ...

Embodiment 2

[0054] The 7.5mm-thick 345MPa-grade anti-seismic structural steel adopts the composition route of vanadium-titanium microalloying, and the steel billet is obtained through molten iron pretreatment, converter smelting, LF heating furnace refining, and continuous casting. The specific chemical composition weight percentage is: 0.15%C-0.13 %Si-1.0%Mn-0.04%V-0.026%Ti-0.014%P-0.010%S; billet reheating temperature is 1220℃, reheating time is 305min; Rates are 28%, 28%, 30%, 30%. 30%, the thickness of the intermediate billet is 36mm; the finish rolling is 6-stand hot continuous rolling, the reduction rate of each pass is 35%, 34%, 0, 25%, 20%, 11%, and the final rolling temperature is 847℃ , after the finish rolling, it is cooled to 605°C at a cooling rate of 17°C / s by means of sparse cooling.

[0055] After testing, the microstructure and properties of the 345MPa-grade seismic steel produced in this example are: Rel: 399MPa, Rm: 546MPa, A: 27.5%, Rel / Rm: 0.73, longitudinal impact e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com