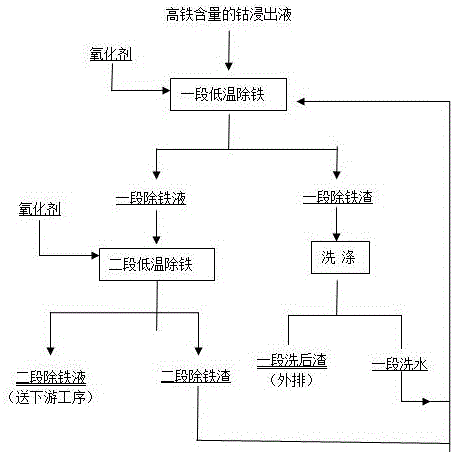

Two-step low-temperature iron removing method for copper-cobalt ore leachate

A leaching solution, copper and cobalt technology, applied in the field of non-ferrous metal smelting, can solve the problems of high valence metals, high temperature iron removal and high energy consumption, and achieve the effect of less valence metal content, good effect and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The main components (g / L) of a copper-cobalt ore leaching solution include: Cu 0.055, Fe 0.98, Co 1.46 and other element contents. First, the copper-cobalt ore leaching solution is subjected to a stage of low-temperature iron removal, and the neutralization hydrolysis method is used to remove iron. The mass ratio is 2:100 mixed gas of sulfur dioxide and air as oxidant, control the potential of the solution at 400mV, the oxidant feed rate of the mixed gas of air and sulfur dioxide is 1.8L / min, control the temperature at 30℃, adjust the end pH of the solution to 2.78 with CaO, remove iron It takes 6 hours to carry out one stage of low-temperature iron removal, and the obtained one stage of iron-removing slag contains 0.022% cobalt; the produced one stage of iron-removal liquid is subjected to a second stage of low-temperature neutralization to remove iron, and a mixture of sulfur dioxide and air with a mass ratio of 2:100 is added. As an oxidant, control the solution potent...

Embodiment 2

[0022] The main components (g / L) of a copper-cobalt ore leaching solution include: Cu 1.965, Fe 3.46, Co 59.53 and other element contents. First, the copper-cobalt ore leaching solution is subjected to a stage of low-temperature iron removal, and the neutralization hydrolysis method is used to remove iron. The mass ratio is 1:100 mixed gas of sulfur dioxide and air is used as oxidant to control the potential of the solution at 460mV, the oxidant input of the mixed gas of air and sulfur dioxide is 2.5L / min, the temperature is controlled to 35℃, the end point of the solution is adjusted to pH3.0 with CaO, and iron is removed For 6h, carry out one stage of low-temperature iron removal, and the obtained one stage of iron-removal slag contains 0.032% of cobalt; the produced one stage of iron-removal liquid is subjected to the second stage of low-temperature neutralization to remove iron, and a mixture of sulfur dioxide and air with a mass ratio of 1:100 is added. As an oxidant, contr...

Embodiment 3

[0024] The main components (g / L) of a copper-cobalt ore leaching solution include: Cu 1.985, Fe 10.63, Co 68.59 and other element contents. First, the copper-cobalt ore leaching solution is subjected to a stage of low-temperature iron removal, and the neutralization hydrolysis method is used to remove iron. The mass ratio is 1:10 mixed gas of sulfur dioxide and air used as oxidant to control the solution potential at 460mV, the oxidant feed rate of the mixed gas of air and sulfur dioxide is 1.8L / min, the temperature is controlled to 15℃, the end point of the solution is adjusted to pH 2.5 with CaO, and iron is removed For 4h, one stage of low-temperature iron removal is carried out, and the obtained one stage of iron removal slag contains 0.036% of cobalt; the produced one stage of iron-removal liquid is subjected to a second stage of low-temperature neutralization to remove iron, and a mixture of sulfur dioxide and air with a mass ratio of 1:10 is added. As an oxidant, control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com