A kind of ultra-low carbon steel rh refining furnace desulfurization method

An ultra-low carbon steel and refining furnace technology, applied in the field of iron and steel metallurgy, can solve the problems of unfavorable desulfurization reaction kinetic conditions, difficulty in further improving desulfurization effect, and slow melting speed of desulfurization agent, etc., to achieve convenient throwing, stable and efficient injection , the effect of prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

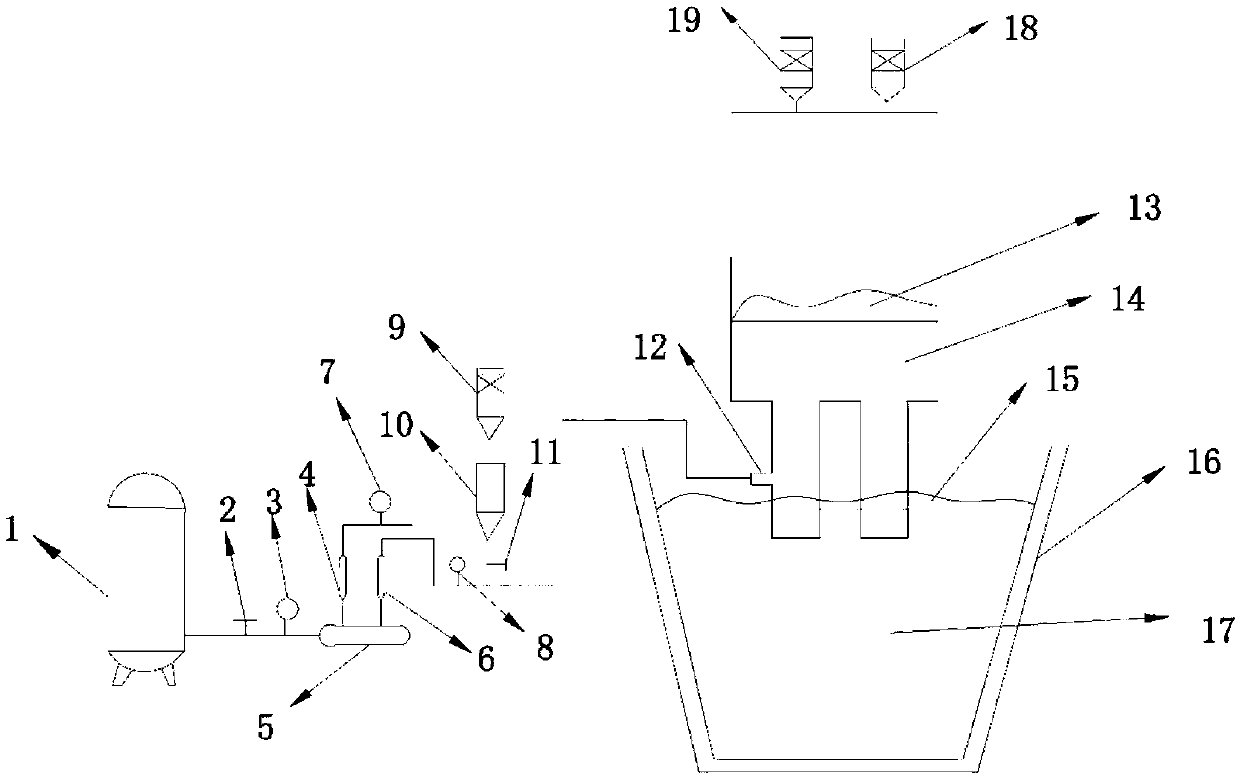

Image

Examples

Embodiment 1

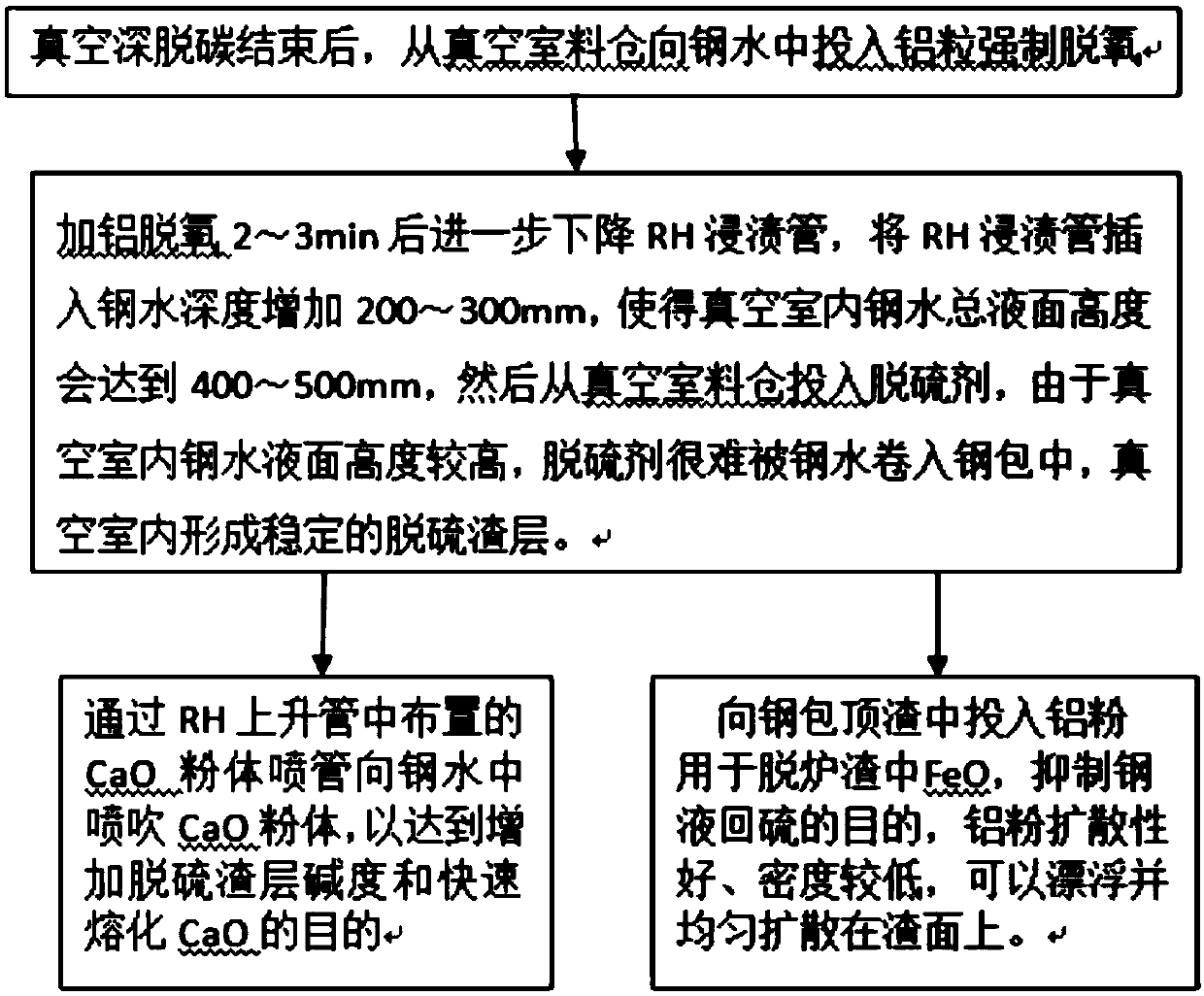

[0034] Such as figure 2 Shown, a kind of ultra-low carbon steel RH refining furnace desulfurization method, described method comprises the following steps:

[0035] 1) The production process of ultra-low carbon steel is formulated as follows: hot metal pretreatment desulfurization → LD (ladle) → slag retaining and tapping → ladle slag reformation → RH (vacuum refining) decarburization and desulfurization → continuous casting;

[0036] 2) The amount of molten steel in the converter is about 120 tons. During the process of putting steel into the converter, 400kg of granular lime is added along with the steel flow. After the steel is placed in the converter, 300kg of special modifier is evenly added to the slag surface / furnace (based on 800ppm of oxygen at the end of converter blowing, For every increase of 100ppm, add 30kg of modifier and 100kg of granular lime / furnace). After the converter is tapped, after the RH enters the station, the temperature is measured and the oxygen i...

Embodiment 2

[0047] Such as figure 2 Shown, a kind of ultra-low carbon steel RH refining furnace desulfurization method, described method comprises the following steps:

[0048] 1) The production process of ultra-low carbon steel is formulated as follows: hot metal pretreatment desulfurization → LD (ladle) → slag retaining and tapping → ladle slag reformation → RH (vacuum refining) decarburization and desulfurization → continuous casting;

[0049] 2) The amount of molten steel in the converter is about 120 tons. During the process of putting steel into the converter, 400kg of granular lime is added along with the steel flow. After the steel is placed in the converter, 300kg of special modifier is evenly added to the slag surface / furnace (based on 800ppm of oxygen at the end of converter blowing, For every increase of 100ppm, add 30kg of modifier and 100kg of granular lime / furnace). After the converter is tapped, after the RH enters the station, the temperature is measured and the oxygen i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com