Method of producing ethanol by fermenting immobilized yeast cells taking waste molasses as raw material

An immobilized yeast and cell fermentation technology, applied in the field of new immobilized yeast cells, can solve the problems of low ethanol yield, increase cost, affect the activity of free cells, etc., achieve low-cost utilization, increase service life, and improve ethanol Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The immobilization of embodiment 1 yeast cell

[0033]3 bottles of seed culture medium (250mL Erlenmeyer flask, liquid volume 120mL): molasses 50g / L (calculated based on the amount of glucose contained in molasses), CaCl 2 0.022g, (NH 4 ) 2 SO 4 0.72g, (NH 4 ) 2 HPO 4 0.36g, MgSO 4 0.036g, yeast powder 1.8g, H 2 O270mL, molasses needs to be sterilized separately and then mixed with other sterilized medium components.

[0034] Preparation of composite immobilized carrier: 300mL of mixed solution of 6% (w / w) PEG and 4% (w / w) SA and 1% (w / w) activated carbon (18 grams of PEG in 300mL mixed solution, 12g of SA , 3g of activated carbon); 5% (w / w) of CaCl 2 300mL of the solution was sterilized at 121°C for 15min respectively.

[0035] Inoculate the strains on the slant of the test tube into the seed medium, culture at 30°C and 200r / min for 20 hours, centrifuge at 6000 rpm for 1min to collect the bacteria, wash the bacteria 3-5 times with sterile normal saline, a...

Embodiment 2

[0036] The optimization experiment of embodiment 2 composite immobilization carrier

[0037] In order to find out the best immobilization conditions, the concentration of the immobilization materials sodium alginate (SA), polyethylene glycol (PEG) and activated carbon was optimized through three factors and three levels of orthogonal experiments, and assuming the relationship between each factor There is no interaction between them.

[0038] According to Example 1, the yeast cells were immobilized and cultured on a shaking table at 200 rpm at 30°C, and the molasses ethanol fermentation experiment was carried out according to the ratio of the volume of the immobilized cells to the volume of the fermentation broth of 1:7, wherein the volume of the fermentation broth was 750ml, temperature 30°C, rotation speed 80rpm, adjust pH to 5.0 with ammonia water, ventilate, record the highest ethanol concentration that can be achieved in the fermentation broth.

[0039] Table 1: Factor le...

Embodiment 3

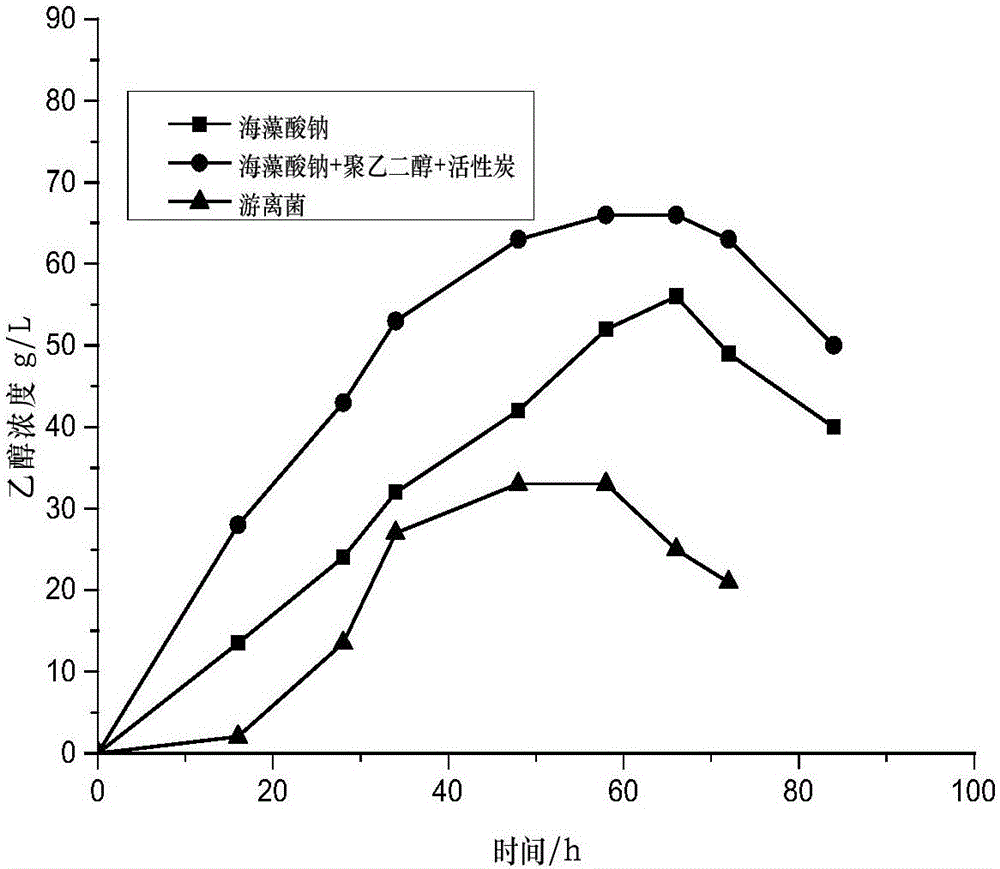

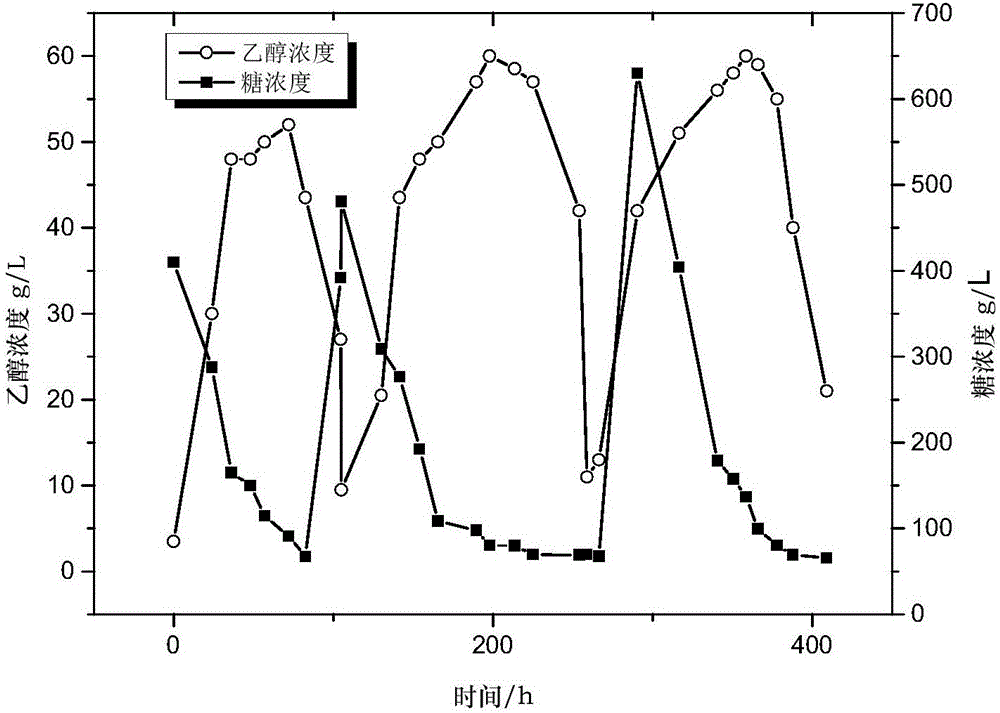

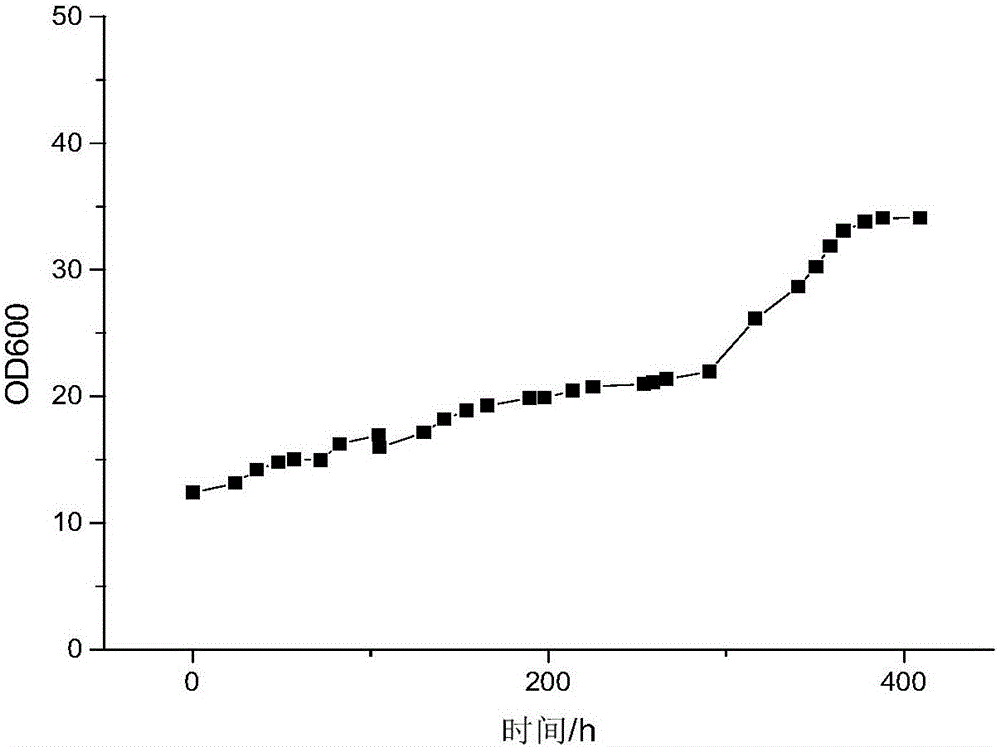

[0044] The control experiment of embodiment 3 free bacteria fermentation and different immobilized carrier fermentation

[0045] In the experiment, after the yeast cells were immobilized according to the method of Example 1, the value-added culture was carried out on a shaker at 200 rpm at 30°C, and the seed culture of free bacteria was used as a control experiment. After 20 hours of value-added culture, the volume of immobilized cells and the fermentation broth The ratio of the volume ratio is 1:7 to the fermentation medium, and the free bacteria are inoculated into the fermentation medium with the same amount of bacteria. The volume of the fermentation broth is 750ml, the temperature is 30°C, the rotation speed is 80rpm, the ammonia water is adjusted to PH5.0, aeration is performed, and samples are taken at regular intervals to measure the production of ethanol and the consumption of sugar. The sugar here is calculated by the total reducing sugar. . Experimental results suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com