Intelligent control type two-phase anaerobic biofilm biogas fermentation system and process

An anaerobic biofilm and intelligent control technology is applied in the field of intelligent control of two-phase anaerobic biofilm biogas fermentation systems and processes, which can solve the problems of unstable yield and low biogas yield, and achieve reasonable structural design and process operation. Simple and effective in improving conversion efficiency and operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

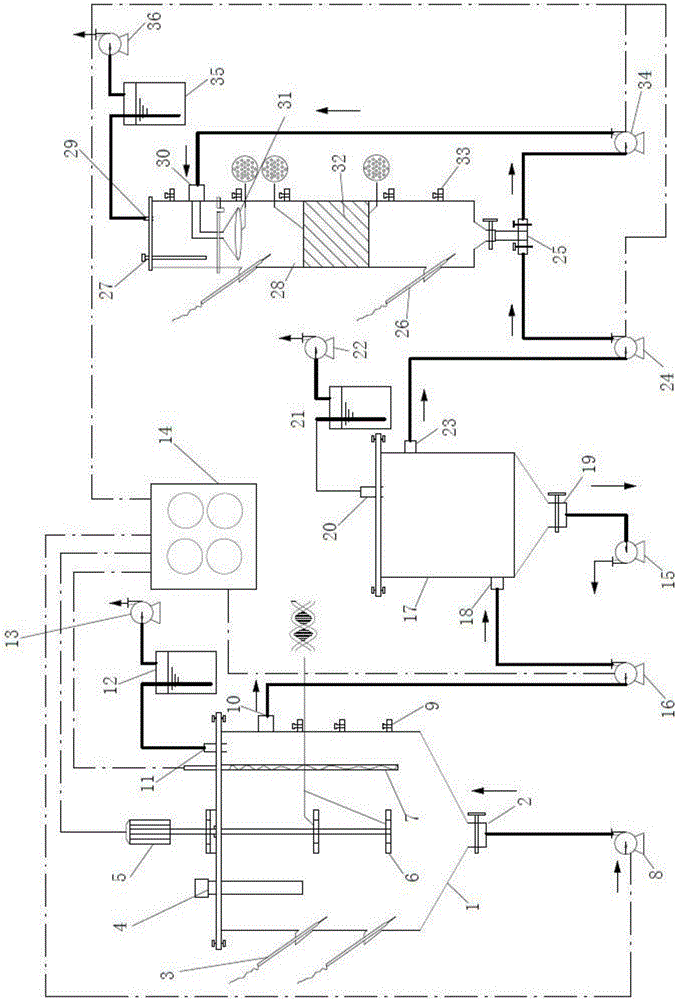

[0024] Such as figure 1 As shown, the intelligent control two-phase anaerobic biofilm biogas fermentation system consists of a hydrolytic acidification phase fermentation device 1, a methanogenic phase fermentation device 28, and an acidification device connected between the hydrolytic acidification phase fermentation device 1 and the methanogenic phase fermentation device 28. Material storage solid-liquid separation device 17 and PLC intelligent controller 14 are composed. The volume ratio of the hydrolysis acidification phase fermentation device 1 , the acidified material storage solid-liquid separation device 17 and the methanogenic phase fermentation device 28 is 4:1:1.

[0025]Wherein, the acidified material storage solid-liquid separation device 17 is provided with an acidified liquid feed port 18 at the lower part, an acidified liquid discharge port 23 at the upper part, a gas outlet 20 at the top, and a residue discharge port 19 at the bottom. A connection pipeline is...

Embodiment 2

[0033] In the intelligently controlled two-phase anaerobic biofilm biogas fermentation system, the volume ratio of the hydrolysis acidification phase fermentation device 1, the acidified material storage solid-liquid separation device 17 and the methanogenic phase fermentation device 28 is 4:1:1. The diameter-to-height ratio of the methanogenic phase fermentation device 28 is 1:8, and the detachable carrier supporting device 32 in the methanogenic phase fermentation device 28 is located at 2 / 3 of the top of the methanogenic phase fermentation device 28, The height of the supported carrier is 1 / 3 of the height of the methanogenic phase fermentation device 28 . Others are the same as embodiment 1.

[0034] The intelligent control of the two-phase anaerobic biofilm biogas fermentation process using the above system includes the following steps:

[0035] Step 1, first separate the sand particles mixed in the pig manure and sewage sludge, then mix with the crushed straw, and final...

Embodiment 3

[0039] In the intelligently controlled two-phase anaerobic biofilm biogas fermentation system, the volume ratio of the hydrolysis acidification phase fermentation device 1, the acidified material storage solid-liquid separation device 17 and the methanogenic phase fermentation device 28 is 3:1:1. The diameter-to-height ratio of the methanogenic phase fermentation device 28 is 1:6, the diameter of the reflux disperser 31 is 4 / 5 of the diameter of the methanogenic phase fermentation device 28, and the detachable carrier supporting device 32 is located at a distance from the methanogenic phase At 2 / 3 of the top of the fermentation device 28, the height of the supporting carrier is 1 / 4 of the height of the fermentation device 28 in the methanogenic phase. Others are the same as embodiment 1.

[0040] The intelligent control of the two-phase anaerobic biofilm biogas fermentation process using the above system includes the following steps:

[0041] Step 1. First separate the sand p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com