Wine distillation device

A technology of wine steaming equipment and fermented grains, which is applied in the preparation of alcoholic beverages and other directions, can solve the problems of mixing and affecting the quality of wine, and achieve the effects of lowering the temperature of the wine, reducing impurities with high boiling points, and being easy to transform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

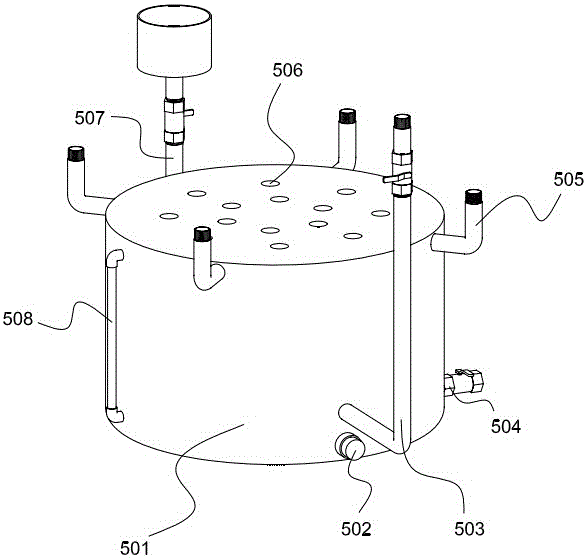

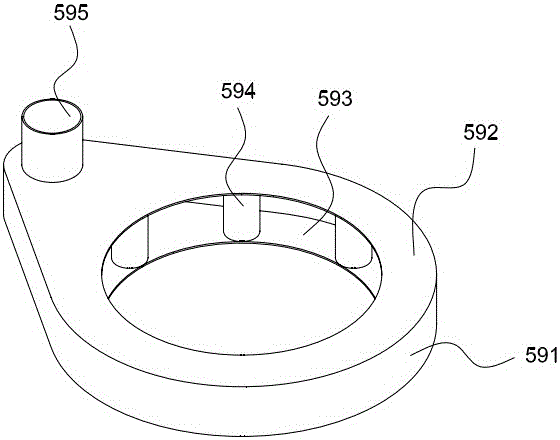

[0030] Such as Figure 1-6 As shown, this embodiment includes a steam generator 501 for generating water vapor required for heating wine grains, a flue device 591, a distillation barrel 400 for containing wine grains, a sky pot condenser 300 covering the distillation barrel 400, And a blower and an air guide pipe for blowing air into the distillation barrel 400 .

[0031] Such as figure 1 As shown, the steam generator 501 is a hollow cylinder, fourteen flue pipes 506 are arranged between the upper bottom surface and the lower bottom surface of the cylinder, the upper end of the flue pipe 506 is welded to the upper bottom surface, and the lower end of the flue pipe 506 It is welded to the lower bottom surface, and the space above the upper bottom surface communicates with the space below the lower bottom surface through the flue pipe 506 . The inner side of the cylinder is provided with a steam generation space containing water and water vapor. Four lower-half steam guide pi...

Embodiment 2

[0040] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , the present embodiment includes a steam generator 501 for generating the water vapor required for heating the fermented grains, a flue device 591, a distillation barrel 400 for containing the fermented grains, a sky pot condenser 300 covering the distillation barrel 400, and A blower blower, an air guide pipe and an air guide circuit pipe for blowing air into the distillation barrel 400.

[0041] Refer to the specific structure of steam generator 501, flue device 591, distillation barrel 400, blower and air guide pipe figure 1 , figure 2 , image 3 , Figure 4 Shown and written description of Example 1.

[0042] Such as Figure 7As shown, the sky pot condenser 300 includes a retort 301 whose shape is similar to the side of a circular platform, and whose upper end is slightly smaller than the lower end. There is a circular cover plate 309 on the upper end of the retort 301, and the circular cov...

Embodiment 3

[0044] refer to figure 1 As shown, there is no "L"-shaped air duct 503 and the air distribution pipe 490 connected with the "L"-shaped air duct 503 on the side of the steam generator in this embodiment. The air guide pipe of this embodiment includes a fixed pipe connected to a lower half steam guide pipe 505, the fixed pipe is a horizontal straight pipe, and a valve is arranged on the horizontal straight pipe. The inner space of the fixed pipe communicates with the inner space of the lower half section of the steam guiding pipe 505 . The air outlet of the blower in this embodiment is welded to one end of a metal pipe, and the other end of the metal pipe is screwed to the fixed pipe.

[0045] Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com