Adhesive film for FPC, preparation method of adhesive film and FPC

A film and adhesive technology, applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc., can solve the problems of short curing time at high temperature, poor high temperature resistance, poor dimensional stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

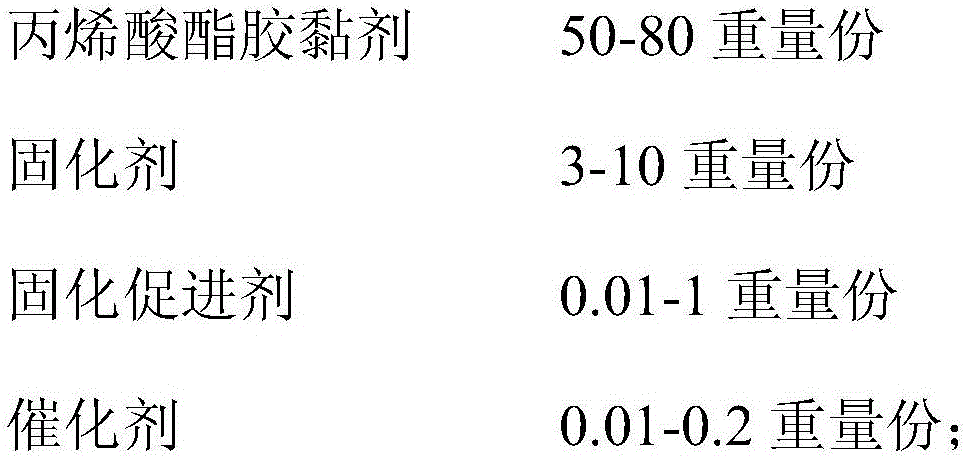

[0032] The present invention also provides a preparation method for the above-mentioned FPC film, the steps comprising: mixing 50-80 parts by weight of an acrylic adhesive, 3-10 parts by weight of a curing agent, and 0.01-1 parts by weight of a curing accelerator , 0.01-0.2 parts by weight of the catalyst, optional 0.05-0.5 parts by weight of the toughening agent, optional 0.05-0.5 parts by weight of the silane coupling agent and solvent mixed, coated on the substrate, dried sticky For layering, the drying temperature can be 100-125°C. Generally, the solvent is evaporated to dryness to form a film, and it takes about 3 minutes. Preferably, the preparation of the acrylate adhesive includes 5-20 parts by weight of soft monomers, 8-30 parts by weight of hard monomers, 0.5-5 parts by weight of functional monomers, 0.01-1.00 parts by weight, preferably 0.01-0.1 After mixing the initiator and the solvent in parts by weight, they are reacted at 50°C-70°C, preferably 60°C-62°C. The s...

Embodiment 1

[0047] (1) First measure 0.03g of p-toluenesulfonic acid, add 2g of ethyl acetate to dissolve, stir evenly, then add 30g of the acrylate adhesive prepared above, 3.6g of benzoxazine resin, 0.08g of 2,4- Mix toluene bisdimethylurea, 0.1g nano-silica, 0.07g KH-560 and 15g toluene, and stir evenly at room temperature;

[0048] (2) Apply the above mixture on the single-side peeling PET film, dry it at 100°C, and then cover with a layer of single-side peeling PET film to obtain sample S1.

Embodiment 2

[0050] (1) First measure 0.03g of p-toluenesulfonic acid, add 2g of ethyl acetate to dissolve, stir evenly, then add 30g of the acrylate adhesive prepared above, 3.6g of benzoxazine resin, 0.1g of 2-ethyl - Mix 4-methylimidazole, 0.1g nano-silicon dioxide, 0.07g KH-560 and 15g toluene, and stir evenly at room temperature;

[0051] (2) Apply the above mixture on the single-side peeling PET film, dry it at 100°C, and then cover it with a layer of single-side peeling PET film to obtain sample S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com