Curable resin composition, and composite material and preparation method thereof

A technology for curing resins and composite materials, which is applied in the field of curable resin compositions, composite materials and their preparation, can solve problems such as poor friendliness, high energy consumption, poor economic and social benefits, etc., achieve rapid curing and reduce production The effect of cost and excellent latency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take a low molecular weight epoxy equivalent of 180-190 in 100 parts of bisphenol A type epoxy resin, into a reaction vessel, 30 parts of bisphenol A was added, heated to 80 ℃, bisphenol A was dissolved with stirring. Was then added 1 part of methyl triphenylphosphonium bromide, after mixing, the temperature was raised to 120 deg.] C, bisphenol A epoxy resin with an exothermic reaction started. After completion of the exotherm, the temperature was raised to 160. deg.] C, the reaction was kept for 3 hours to obtain a first component.

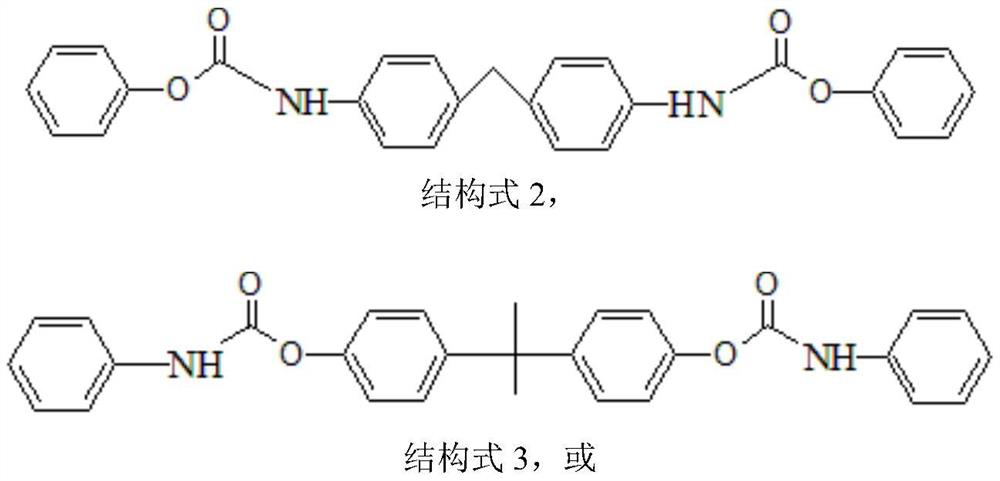

[0035] Take a small molecule compound represented by the formula 2, as the second component.

[0036]

[0037] The first and second components, according to the ratio of 80:20, mixed at 80 deg.] C, cooled to 25 deg.] C standby, the composition 1.

[0038] After 30 days storage at room temperature, the above-described composition 1 is not yet crosslinked and cured.

[0039] The above-described composition 1 was placed in an oven at 120 deg.] ...

Embodiment 2

[0041] Taken 180-190 epoxy equivalent of low molecular weight bisphenol A epoxy resin 90 parts and 10 parts of novolac type epoxy resin (NPPN-638S, commercially available epoxy resin to South (Kunshan) Co., Ltd.), into the reaction vessel, was added 30 parts of bisphenol A, was heated to 80 ℃, bisphenol A was dissolved with stirring. After cooling down to less than 40 ℃ 1 part of triphenylphosphine was added, stirred uniformly, to obtain the first component.

[0042] Take formula 2, a small molecule compound represented by formula 1 3: 1 mixture of the second component.

[0043]

[0044] The first and second components, according to the ratio of 70:30, mixed at 60 deg.] C, the composition 2.

[0045] After 30 days storage at room temperature, the above compositions 2, an increase in viscosity, but no crosslinking.

[0046] The above composition is 2, taken into an oven at 120 deg.] C after 2 hours, has been found to crosslinking.

Embodiment 3

[0048] Take Example 2 Preparation of composition 2 at 60 ℃ immersed carbon fiber sheet, made of a prepreg. The above-mentioned prepreg, the thickening at 40-45 ℃ for 24 hours, the viscosity of the resin increases, the fluidity is deteriorated.

[0049] The above-described prepreg on a mold paving, with a hydraulic press nip, incubated at 150 ℃ 5 min. Releasing, to obtain a carbon fiber-reinforced composite sheet a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com