Hexagonal boron nitride epoxy anticorrosive wear-resistant paint as well as preparation method and application thereof

A hexagonal boron nitride, anti-corrosion and wear-resistant technology, applied in the field of coatings, can solve the problems of poor coating protection effect, easy agglomeration, and difficulty in uniform dispersion, so as to increase wear resistance, improve barrier performance, and reduce coating cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

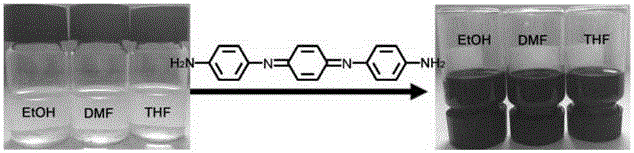

[0056] In some preferred embodiments, the preparation method includes: dispersing hexagonal boron nitride and aniline oligomers in a solvent, and stirring or ultrasonic treatment to obtain a hexagonal boron nitride dispersion, and then dissolving the hexagonal boron nitride The boron nitride dispersion liquid is mixed with epoxy resin and coating additives to obtain the first component.

[0057] Further, in the aforementioned preparation method, general high-speed stirring and mixing and dispersing equipment can be used for stirring and dispersing, such as ultrasonic cleaning machines, ultrasonic cell pulverizers, high-speed mixers, mechanical stirrers, etc.

[0058] Further, the content of hexagonal boron nitride in the coating is preferably 0.5wt%-2wt%.

[0059] Further, the mass ratio of hexagonal boron nitride to aniline oligomers in the coating is preferably 1:10˜10:1.

[0060] In some preferred embodiments, the coating includes:

[0061] The first component includes: 8...

Embodiment 1

[0095] Example 1: Weigh 0.031 g of aniline dimer and 0.13 g of hexagonal boron nitride nanosheets (commercially available, with a thickness of about 0.33 nm to 2 nm) and disperse them in 25 mL of tetrahydrofuran, and sonicate for 1 hour to obtain a hexagonal boron nitride dispersion. Add the hexagonal boron nitride dispersion to 20g epoxy resin, 1g leveling agent (polydimethylsiloxane), 1g anti-settling agent (polyamide wax), 2g defoamer (modified organic silicone Compound) and 6g xylene, using mechanical stirring for 30 minutes, so that the various substances were mixed uniformly to obtain component one. Mix 5g of polyamide 650 and 4g of xylene solution evenly to prepare component 2. Mix component one and component two according to 4:1, use a high-speed mixer, and stir for 30 minutes to obtain a hexagonal boron nitride epoxy composite coating containing 0.5wt% hexagonal boron nitride (that is, hexagonal boron nitride anti-corrosion and wear-resistant coating). The obtained ...

Embodiment 2

[0096]Example 2: Weigh 0.063g of aniline trimer and 0.25g of hexagonal boron nitride nanosheets (commercially available, with a thickness of about 6nm to 10nm) and disperse them in 50mL of tetrahydrofuran, and sonicate for 1 hour to obtain a hexagonal boron nitride dispersion. Add the hexagonal boron nitride dispersion to 20g epoxy resin, 2g leveling agent (polydimethylsiloxane), 2g anti-settling agent (polyamide wax), 2g defoamer (modified organic silicone Compound) and 6g of toluene (model E44, purchased from Jiangsu Wujiang Heli Resin Factory), mechanically stirred for 30 minutes to mix the various substances uniformly to obtain component 1. Mix 5g of polyamide 650 and 4g of toluene solution evenly to prepare component 2. Mix component one and component two according to 4:1, use a high-speed mixer, and stir for 30 minutes to obtain a hexagonal boron nitride epoxy composite coating containing 1.0 wt% hexagonal boron nitride. The obtained hexagonal boron nitride epoxy compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com