POM flame retardant plastic and preparation method thereof

A technology of flame-retardant plastics and flame-retardant fibers, which is applied in the field of POM flame-retardant plastics and its preparation, can solve the problems of hydrogen halide hazards and the performance of POM flame-retardant plastics that cannot meet the requirements, and achieve low product cost, protection of human health, and durability. Excellent heat resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

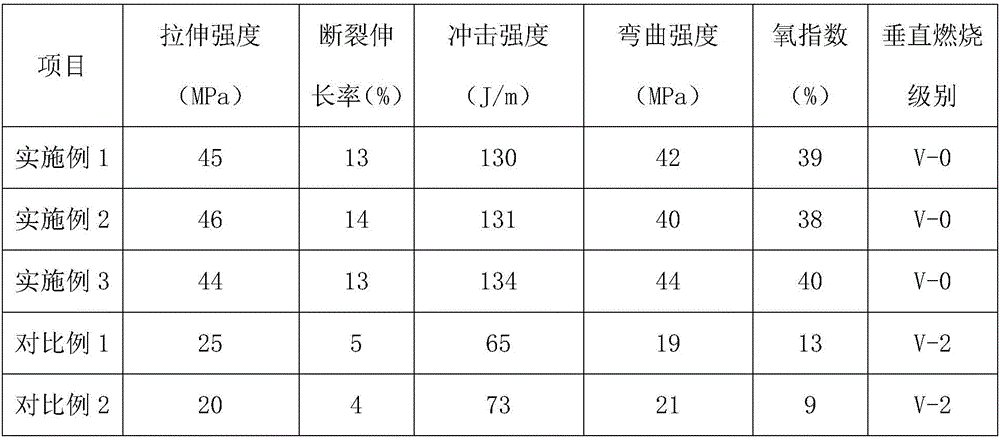

Examples

Embodiment 1

[0016] A POM flame-retardant plastic, consisting of the following raw materials in parts by weight: 150 parts of POM resin, 25 parts of melamine, 10 parts of sodium silicate, 2 parts of bis(triphenylphosphine)palladium dichloride, and 2 parts of aluminum hydroxide , 2 parts of talcum powder, 2 parts of triallyl isocyanurate, 3 parts of potassium perrhenate, 1 part of kaolin, 0.5 part of tantalum pentoxide, 0.1 part of lanthanum hexaboride, and 2 parts of flame-retardant fiber.

[0017] A kind of preparation method of POM flame-retardant plastics, concrete steps are: (1) weigh POM resin, melamine, sodium silicate, bis(triphenylphosphine) palladium dichloride, aluminum hydroxide, talcum powder by weight parts , triallyl isocyanurate, potassium perrhenate, kaolin, tantalum pentoxide, lanthanum hexaboride, flame retardant fiber, standby; (2) put the POM resin into the vacuum granulation kneader, add Melamine, triallyl isocyanurate, sodium silicate, aluminum hydroxide and flame-ret...

Embodiment 2

[0019] A POM flame-retardant plastic, consisting of the following raw materials in parts by weight: 200 parts of POM resin, 30 parts of melamine, 15 parts of sodium silicate, 8 parts of bis(triphenylphosphine) palladium dichloride, and 5 parts of aluminum hydroxide , 5 parts of talcum powder, 8 parts of triallyl isocyanurate, 5 parts of potassium perrhenate, 3 parts of kaolin, 2 parts of tantalum pentoxide, 1 part of lanthanum hexaboride, and 10 parts of flame-retardant fiber.

[0020] A kind of preparation method of POM flame-retardant plastics, concrete steps are: (1) weigh POM resin, melamine, sodium silicate, bis(triphenylphosphine) palladium dichloride, aluminum hydroxide, talcum powder by weight parts , triallyl isocyanurate, potassium perrhenate, kaolin, tantalum pentoxide, lanthanum hexaboride, flame retardant fiber, standby; (2) put the POM resin into the vacuum granulation kneader, add Melamine, triallyl isocyanurate, sodium silicate, aluminum hydroxide and flame-ret...

Embodiment 3

[0022] A POM flame-retardant plastic, consisting of the following raw materials in parts by weight: 182 parts of POM resin, 27 parts of melamine, 12 parts of sodium silicate, 5 parts of bis(triphenylphosphine) palladium dichloride, and 3.5 parts of aluminum hydroxide , 4 parts of talcum powder, 2.8 parts of triallyl isocyanurate, 4.6 parts of potassium perrhenate, 2.8 parts of kaolin, 0.9 part of tantalum pentoxide, 0.4 part of lanthanum hexaboride, and 4 parts of flame-retardant fiber.

[0023] A kind of preparation method of POM flame-retardant plastics, concrete steps are: (1) weigh POM resin, melamine, sodium silicate, bis(triphenylphosphine) palladium dichloride, aluminum hydroxide, talcum powder by weight parts , triallyl isocyanurate, potassium perrhenate, kaolin, tantalum pentoxide, lanthanum hexaboride, flame retardant fiber, standby; (2) put the POM resin into the vacuum granulation kneader, add Melamine, triallyl isocyanurate, sodium silicate, aluminum hydroxide and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com