Anti-impact anti-aging plastic drum and preparation method thereof

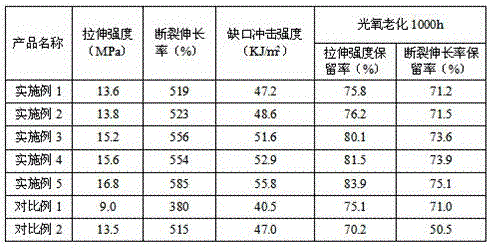

A plastic barrel, aging-resistant technology, applied in the field of packaging containers, can solve problems such as impact strength, and achieve the effects of high elongation at break, high tensile strength, and good aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An anti-shock and anti-aging plastic barrel, which is prepared from the following components by weight: 75 parts of high-density polyethylene, 25 parts of polypropylene, 5 parts of talcum powder, 0.2 parts of silane coupling agent A-151, antioxidant 0.1 part of 1076, 0.1 part of antioxidant 1010, 0.5 part of phosphite, 0.1 part of ethylene bis stearic acid amide, 1 part of dimethyl phthalate, 10 parts of glass fiber, acrylic modified high density polyethylene 5 parts of ethylene, 5 parts of isocyanate-terminated polyether polyurethane graft modified epoxy resin, 10 parts of hyperbranched borate modified phenolic resin, 0.2 part of phenyl benzimidazole sulfonic acid, 3-4'-methyl 1 part of benzylidene-d-L-camphor.

[0018] The preparation method of the above-mentioned anti-shock and anti-aging plastic bucket is as follows: (1) grafting modified epoxy resin, The hyperbranched borate-modified phenolic resin was placed in a mixer and stirred for 20 minutes at a temperature ...

Embodiment 2

[0020] An anti-shock and anti-aging plastic barrel, which is prepared from the following components by weight: 95 parts of high-density polyethylene, 15 parts of polypropylene, 8 parts of talcum powder, 0.6 parts of silane coupling agent A-151, antioxidant 0.4 parts of 1076, 1 part of antioxidant 1010, 0.1 part of phosphite, 1 part of ethylene bis stearic acid amide, 2 parts of dimethyl phthalate, 30 parts of glass fiber, acrylic modified high-density polyethylene 10 parts of ethylene, 10 parts of isocyanate-terminated polyether polyurethane graft modified epoxy resin, 5 parts of hyperbranched borate modified phenolic resin, 1 part of phenyl benzimidazole sulfonic acid, 3-4'-methyl 0.2 parts of benzylidene-d-L-camphor.

[0021] The preparation method of the above-mentioned anti-shock and anti-aging plastic bucket is as follows: (1) grafting modified epoxy resin, The hyperbranched borate-modified phenolic resin was placed in a mixer and stirred for 40 minutes at a temperature ...

Embodiment 3

[0023] An anti-shock and anti-aging plastic bucket, prepared from the following ingredients by weight: 80 parts of high-density polyethylene, 18 parts of polypropylene, 6 parts of talcum powder, 0.3 parts of silane coupling agent A-151, antioxidant 0.3 parts of 1076, 0.3 parts of antioxidant 1010, 0.4 parts of phosphite, 0.3 parts of ethylene bis stearic acid amide, 1.2 parts of dimethyl phthalate, 15 parts of glass fiber, acrylic modified high density polyethylene 8 parts of ethylene, 6 parts of isocyanate-terminated polyether polyurethane graft modified epoxy resin, 8 parts of hyperbranched borate modified phenolic resin, 0.4 part of phenyl benzimidazole sulfonic acid, 3-4'-methyl 0.8 parts of benzylidene-d-L-camphor.

[0024] The preparation method of the above-mentioned anti-shock and anti-aging plastic bucket is as follows: (1) grafting modified epoxy resin, The hyperbranched borate-modified phenolic resin was placed in a mixer and stirred for 25 minutes at a temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com