Preparation method of perovskite quantum dot/polymer composite fluorescent film

A composite fluorescence and polymer technology, applied in the field of luminescent composite materials and luminescent materials, can solve the problems of large amount of raw materials, complicated and complicated processes, low efficiency, etc., and achieve the effect of promoting continuous production and optimizing the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1CH 3 NH 3 PbBr 3 / Continuous tape casting of PVDF composite luminescent film (1)

[0061] In an environment with a relative humidity 2 0.4mmol, CH 3 NH 3 0.4 mmol of Br (methylamine bromide), 10 g of polymer component PVDF and 0.05 g of organic amine component n-octylamine were dissolved in 100 mL of organic solvent dimethyl sulfoxide to obtain a mixed solution. The mixed solution was processed through the following steps in turn: mechanical stirring for 1 hour, high-speed dispersion for 30 minutes, high-mesh filter to remove impurities, centrifugation to remove air bubbles, and vacuum to further remove air bubbles. Finally, the film-forming solution used in the next stage was obtained and sealed. stand-by.

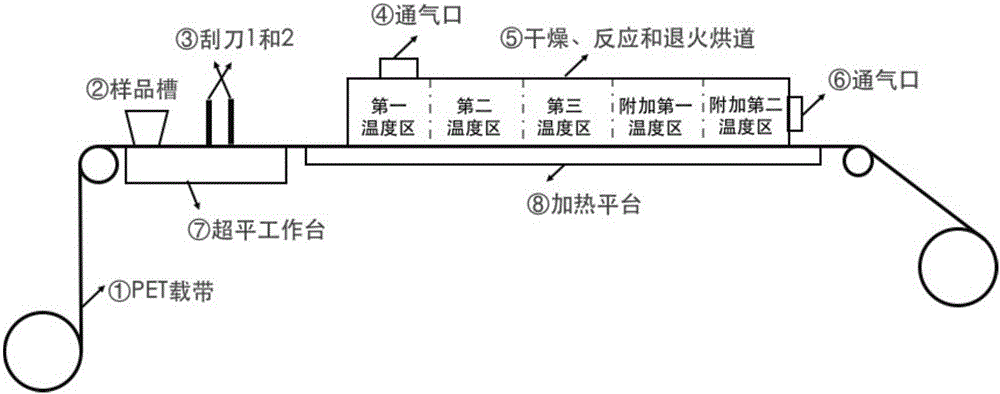

[0062]Pre-set the temperature of the multi-stage drying oven (the length of each drying oven is 1m) of the tape casting equipment, in order: the first section is 70°C, the second section is 60°C, the third section is 50°C, and the first section is 6...

Embodiment 2

[0066] Example 2CH 3 NH 3 PbBr 3 / Continuous tape casting of PVDF composite luminescent film (2)

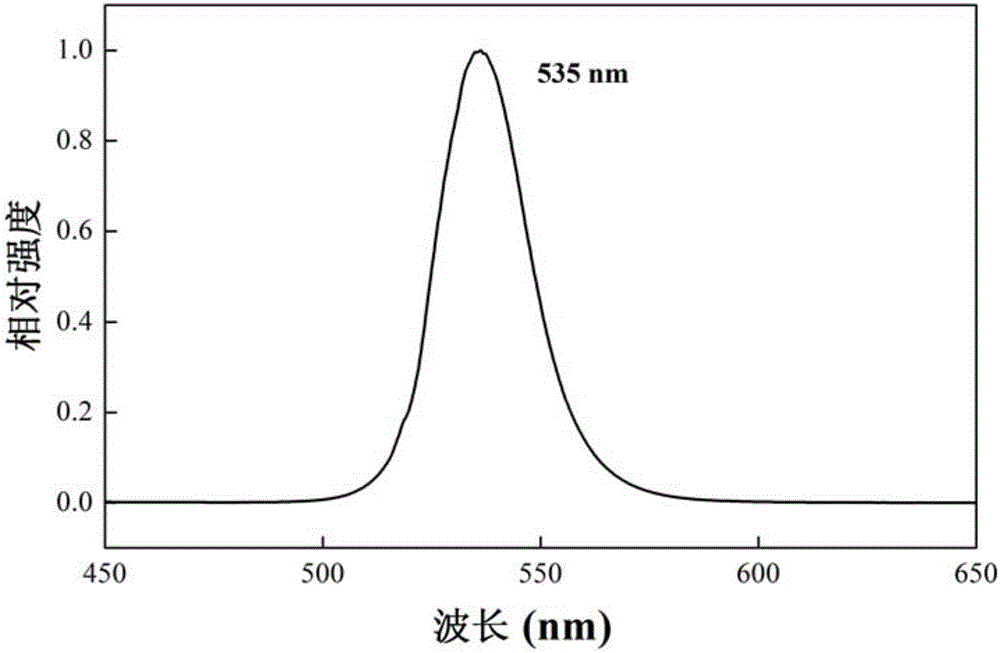

[0067] Repeat the experimental procedure of Example 1, change the organic solvent dimethyl sulfoxide 100mL to the mixed solvent dimethyl sulfoxide 60mL / acetone 40mL, and set the speed of the membrane belt entering the drying tunnel to 0.3m / min. The obtained composite luminescent film is translucent green, and the same test method is used to characterize the composite luminescent film. The luminescent wavelength is 535nm, the half-maximum width is 28nm, the fluorescence quantum yield is 74%, and the light transmittance is 79% (550nm- 900nm). Under the same drying conditions, the use of a mixed solvent system can speed up the casting drying speed of the composite luminescent film, shorten the drying time, and improve production efficiency. The fluorescence emission spectrum of the composite luminescent film is as follows figure 2 shown.

Embodiment 3

[0068] Example 3CH 3 NH 3 PbBr 3 / Continuous tape casting of PVDF composite luminescent film (3)

[0069] The experimental procedure of Example 1 was repeated, except that 0.05 g of n-octylamine was not added as an additive. The obtained composite luminescent film is pale yellow, and the same test method is used to characterize the composite luminescent film. The luminescent wavelength is 530nm, the half-maximum width is 31nm, the fluorescence quantum yield is 23%, and the light transmittance is 41% (550nm-900nm ). The addition of organic amine additives can greatly increase the fluorescence quantum yield of the prepared composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Luminous wavelength | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com