Feather protein grafted copolymer sizing material and preparation method thereof

A technology of graft copolymer and feather protein, which is applied in the direction of plant fiber, fiber type, textile and paper making, etc., can solve the problems of complex process, low adhesion of polyester fiber, high production cost, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

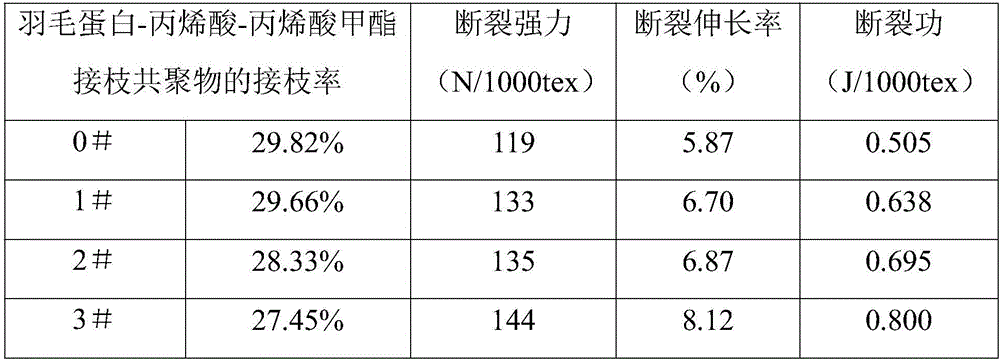

Embodiment 1

[0023] The dry weight of 100g washed and chopped poultry feathers was dispersed in 1900g distilled water to prepare a suspension with a mass concentration of 5%, and then moved into a 5000mL three-necked flask equipped with a mechanical stirrer, a thermometer and a dropping funnel. Stir, heat up, and after the suspension reaches 70°C, add the reducing agent——NaHSO dropwise within 15 minutes 3 aqueous solution, where NaHSO 3 The dosage is 40% of the protein quality of feathers, the mass percentage of feathers in the whole suspension is 4%, keep stirring and reducing at 70°C for 4h, filter, wash with distilled water for 3 to 4 times, and dry the reduced feathers in an oven product;

[0024] The dry weight is that 100g feather product after reduction treatment is dispersed in 900g distilled water, is mixed with the suspension that mass concentration is 10%, then moves in the 2000mL three-neck flask that mechanical stirring, thermometer and dropping funnel are housed, stirs , he...

Embodiment 2

[0035] Adopt the method and step of embodiment 1, change the kind of acrylate monomer, change it into ethyl acrylate, the monomer molar ratio of ethyl acrylate and acrylic acid is 2:8, vinyl monomer (comprising acrylic acid monomer and acrylic acid Ethyl ester monomer) and the mass percent of feather protein powder are 46%, and all the other steps are identical with embodiment 1. See Table 3 for the water solubility and water-soluble stability of the feather protein-acrylic acid-ethyl acrylate graft copolymer slurry measured by visual observation method at pH=6.5, and the feather protein-acrylic acid-ethyl acrylate graft copolymer slurry measured by the roving method The adhesion performance of ester graft copolymer size to polyester fiber is shown in Table 4.

Embodiment 3

[0037] Adopt the method and step of embodiment 1, change the type of acrylate monomer, change it into butyl acrylate, the monomer molar ratio of butyl acrylate and acrylic acid is 2:8, vinyl monomer (comprising acrylic acid monomer and acrylic acid Butyl ester monomer) and the mass percent of feather protein powder are 52%, all the other steps are identical with embodiment 1. See table 3 for the water solubility and water-soluble stability of the feather protein-acrylic acid-butyl acrylate graft copolymer slurry measured by visual observation method at pH=6.5, and the feather protein-acrylic acid-butyl acrylate graft copolymer slurry measured by the roving method The adhesion performance of ester graft copolymer size to polyester fiber is shown in Table 4.

[0038] The water solubility of table 3 feather protein-acrylic acid-acrylate graft copolymer slurry

[0039]

[0040] Remarks: In Table 3, when synthesizing feather protein-acrylic acid-acrylate graft copolymer, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com