Comprehensive treatment and utilization method of waste acid with high zinc content

A comprehensive treatment, sodium chlorate technology, applied in the field of industrial wastewater treatment, can solve the problems of high cost, complex process, and no consideration of acid consumption stage treatment, etc., to achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

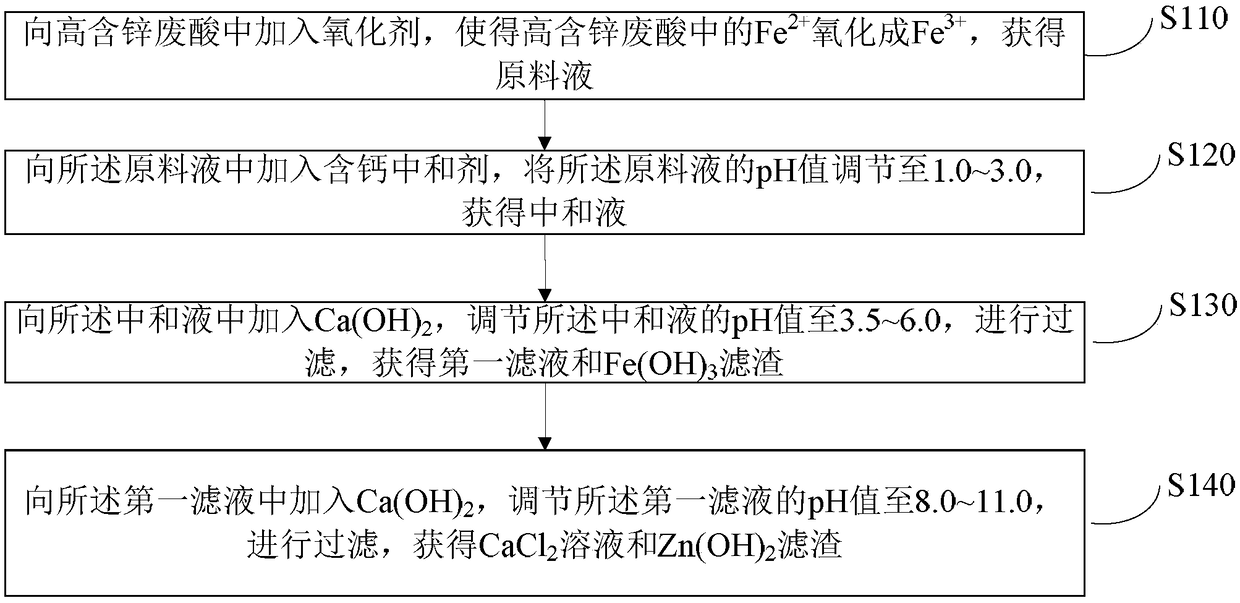

Method used

Image

Examples

Embodiment 1

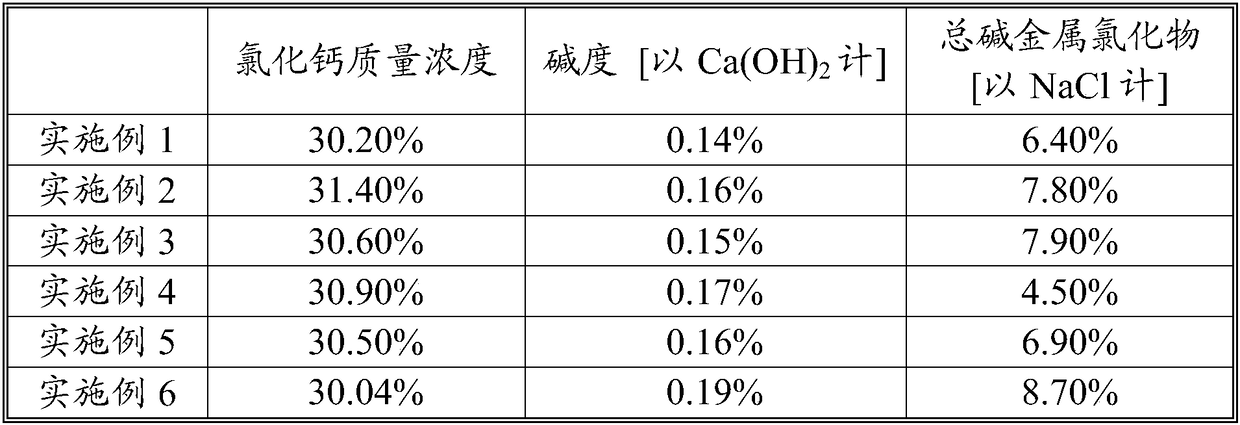

[0055] 2.3t high zinc-containing waste acid (which contains 3.14% iron, 12.89% zinc, acidity [calculated as HCl] is 3.87%) is press-filtered, and the filtrate is poured into the 1# reaction tank, and sodium chlorate is used as the oxidant, and the Add sodium chlorate to the 1# reaction tank for oxidation reaction. After the oxidation reaction is over, it is detected that there is no Fe in the solution. 2+ , it is considered qualified for oxidation.

[0056] Then add calcium carbonate to carry out the acid consumption reaction, adjust the pH value to 1.0 and finish the acid consumption, then add calcium hydroxide to carry out the iron precipitation reaction, adjust the pH value to 3.5 and then finish the iron precipitation reaction, start the discharge pump, and send the feed liquid to Press filter to the filter press, and the filter residue is sent to FeCl 3 The iron pool in the preparation workshop is used as raw material for the production of ferric chloride water purifier,...

Embodiment 2

[0059] 2.12t of high zinc-containing waste acid (which contains 3.14% iron, 12.89% zinc, and 3.87% acidity [calculated as HCl]) is subjected to pressure filtration, and the filtrate is poured into 1# reaction tank, and sodium chlorate is used as an oxidant. Add sodium chlorate to the 1# reaction tank for oxidation reaction. After the oxidation reaction is over, it is detected that there is no Fe in the solution. 2+ , it is considered qualified for oxidation. Then add calcium carbonate to carry out the acid consumption reaction, adjust the pH value to 1.5 and then finish the acid consumption, then add calcium hydroxide to carry out the iron precipitation reaction, adjust the pH value to 4.5 and then finish the iron precipitation reaction, start the discharge pump, and send the feed liquid to Press filter to the filter press, and the filter residue is sent to FeCl 3 The iron pool in the preparation workshop is used as raw material for the production of ferric chloride water pur...

Embodiment 3

[0062] 1.86t high zinc-containing waste acid (which contains 9.14% iron, 5.82% zinc, and acidity [calculated as HCl] is 3.13%) is subjected to pressure filtration, and the filtrate is poured into 1# reaction tank, and sodium chlorate is used as an oxidant. Add sodium chlorate to the 1# reaction tank for oxidation reaction. After the oxidation reaction is over, it is detected that there is no Fe in the solution. 2+ , it is considered qualified for oxidation. Then add calcium carbonate to carry out the acid consumption reaction, adjust the pH value to 2.8 and then finish the acid consumption, then add calcium hydroxide to carry out the iron precipitation reaction, adjust the pH value to 5.5 and then finish the iron precipitation reaction, start the discharge pump, and send the feed liquid to Press filter to the filter press, and the filter residue is sent to FeCl 3 The iron pool in the preparation workshop is used as raw material for the production of ferric chloride water puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com