A kind of processing method and processing system of mixed acid

A treatment system and mixed acid technology, applied in chemical instruments and methods, halogen/halogen acid, chlorine/hydrogen chloride, etc., can solve the problems affecting the normal production process of potassium sulfate and the production cost of potassium sulfate, so as to save construction costs and realize The effect of processing utilization and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The present embodiment provides a kind of processing method of the mixed acid that produces when adopting Mannheim method to produce potassium sulfate, comprises:

[0052] Adopt Mannheim method to produce potassium sulfate, obtain by-product mixed acid;

[0053] Mixing the mixed acid with hydrochloric acid to obtain a mixed solution;

[0054] The limestone is used to react with the mixed solution to produce calcium chloride.

[0055] When the Mannheim method is used to produce potassium sulfate, potassium chloride and sulfuric acid react in the Mannheim furnace to generate potassium sulfate and high-temperature hydrogen chloride gas. Pass the gas containing hydrogen chloride discharged from the reaction chamber into the mixed acid washing tower to wash away the sulfate ions, and then absorb the gas discharged from the mixed acid washing tower with water to obtain hydrochloric acid with high purity. At the same time, mixed acid containing a large amount of chloride ion...

Embodiment 2

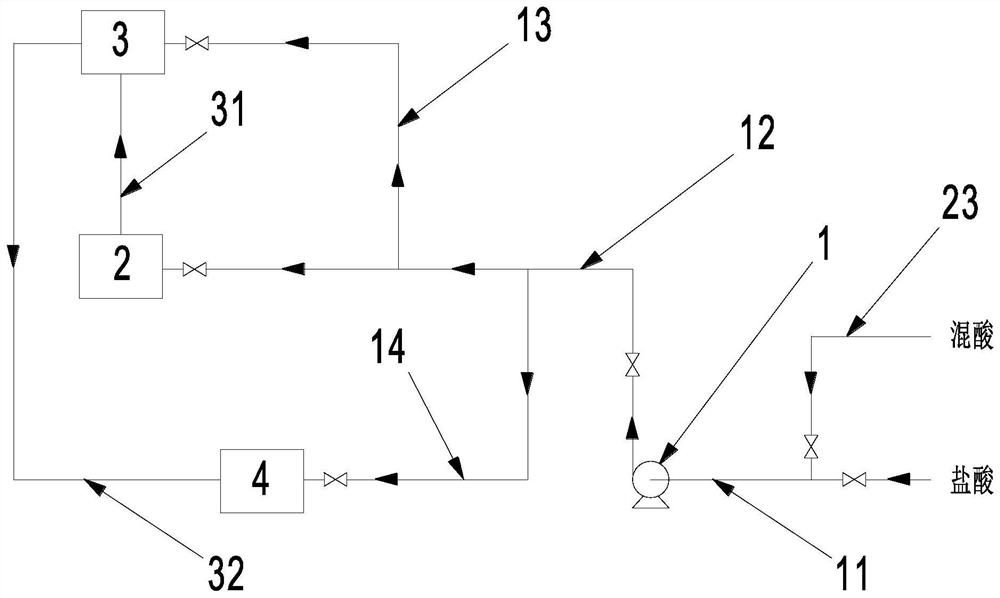

[0069] like figure 1 As shown, this embodiment provides a mixed acid treatment system, including a hydrochloric acid delivery unit, a mixed acid addition unit and a calcium chloride production unit.

[0070] Specifically, the hydrochloric acid delivery unit includes a hydrochloric acid delivery pump 1, a first delivery pipeline 11 communicating with the hydrochloric acid storage device and the inlet of the hydrochloric acid delivery pump 1, and a second delivery pipeline 12 communicating with the outlet of the hydrochloric acid delivery pump 1.

[0071] The mixed acid adding unit includes a mixed acid storage device (not shown in the figure) and a mixed acid delivery pipeline 23 . The inlet end of the mixed acid delivery pipeline 23 communicates with the mixed acid storage device, and the outlet end of the mixed acid delivery pipeline 23 communicates with the first delivery pipeline 11 .

[0072] Described calcium chloride production unit comprises the acid calcium reactor 2 ...

Embodiment 3

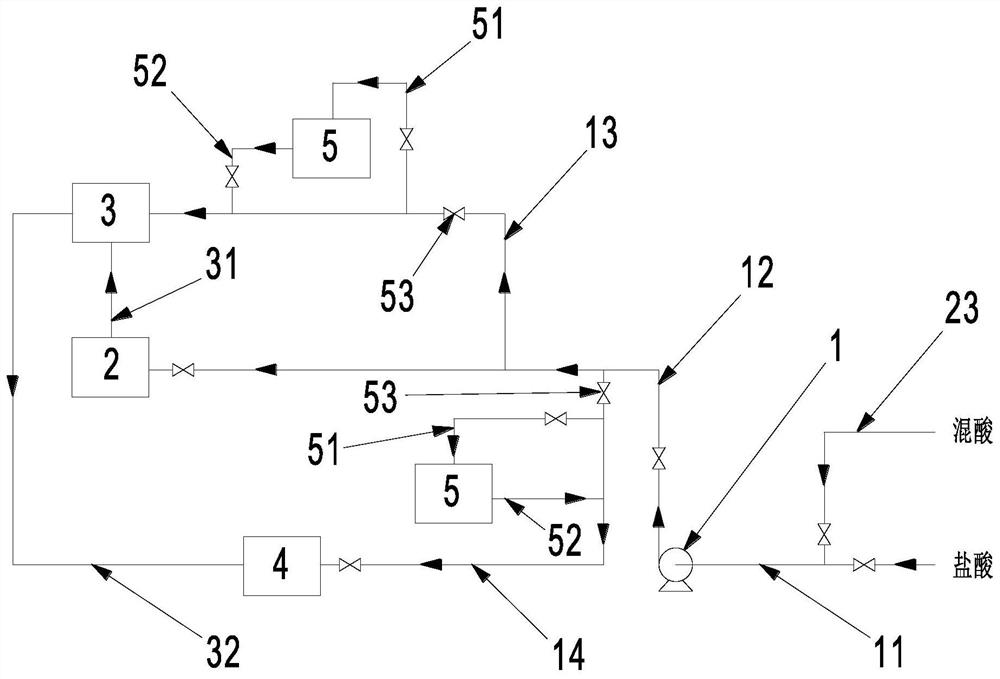

[0083] like figure 2 As shown, this embodiment is a further limitation of the second embodiment above, and the treatment system further includes a buffer tank 5 for storing hydrochloric acid, and the buffer tank 5 is connected with a buffer inlet pipe 51 and a buffer outlet pipe 52 . Both the buffer inlet pipe 51 and the buffer outlet pipe 52 are in communication with the third delivery pipeline 13 and the fourth delivery pipeline 14, between the inlet ends of the third delivery pipeline 13 and the fourth delivery pipeline 14 and the inlet end of the buffer inlet pipe 51 There is also a valve 53 for cutting off the solution in the pipeline.

[0084] In this embodiment, when the staff closes the valve 53 to stop the mixed solution of mixed acid and hydrochloric acid from passing into the third delivery pipeline 13 and the fourth delivery pipeline 14, because the installation position of the buffer tank 5 is higher, the corresponding buffer tank 5 The hydrochloric acid flows i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com