Skarn copper mine beneficiation method

A beneficiation method, skarn technology, applied in the field of skarn copper ore beneficiation, can solve the problems of reducing the economic benefit of the enterprise, deteriorating the flotation slurry environment, and large ore circulation, so as to increase the economic benefit of the enterprise and ensure the copper Concentrate quality and the effect of improving copper recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

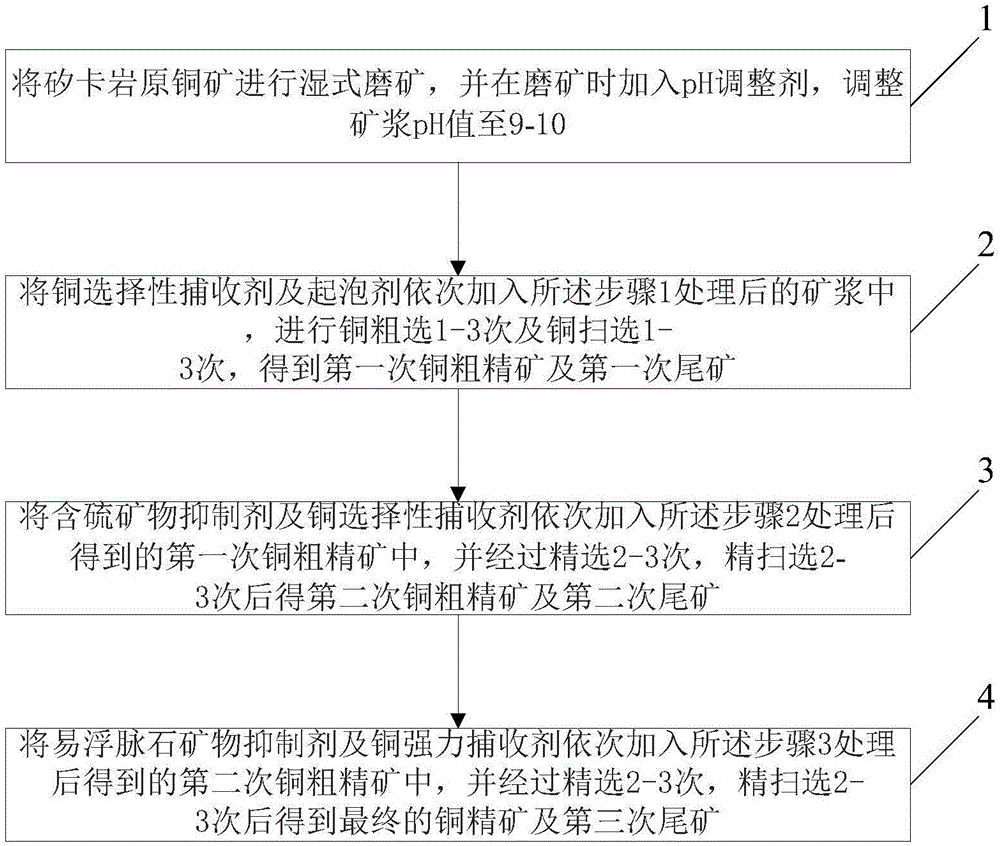

Image

Examples

Embodiment 1

[0038] Embodiment 1, a certain place in Anhui contains gangue copper ore, and the raw ore contains 0.64% copper and 5.1% sulfur. Technological mineralogy research shows that the copper-containing minerals in this ore are mainly chalcopyrite, the sulfur-containing minerals are mainly pyrite, the gangue minerals are mainly quartz and feldspar, and there are more floating gangue minerals, such as Serpentine, talc, chlorite, etc., whose mineral composition accounts for about 8%, is a typical high-sulfur copper ore containing pumice-containing gangue.

[0039] First, the raw ore is subjected to wet grinding, and the grinding fineness is -0.074mm, accounting for 68%, and the pH regulator CaO is added during the grinding to adjust the pH value of the slurry to 9-10.

[0040] Using thiourethane as the copper selective collector and terpineol as the foaming agent, after one roughing and three sweepings, copper coarse concentrate 1 and tailings 1 are obtained. Among them, the amount of...

Embodiment 2

[0044] Example 2, a skarn-type copper mine in Hubei has a complex mineral composition, and the metal minerals in the ore include pyrite, chalcopyrite, copper blue, blue chalcocite, arsenite, magnetite, molybdenite, Pyrhotite, galena, sphalerite, etc.; gangue minerals include quartz, feldspar (potassium feldspar and plagioclase), mica (muscovite, biotite, phlogopite), actinolite, tremolite , variable pyroxene, garnet (grossmantine, andandrite), chlorite, talc, serpentine, pyrophyllite, kaolinite, siderite, calcite, apatite, rutile, sphene Stone, olivine, phosphate aluminum, zircon and so on. Among them, the recyclable metal element is mainly copper, the copper grade is 0.95%, and the sulfur content of the ore is also relatively high, the sulfur grade is 12.1%. In addition, because there are many types of floating gangue in the ore, especially talc, kaolinite, pyrophyllite, chlorite, etc. (the relative content of minerals accounts for about 4.67%), it is easy to affect the qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com