Bismuth tungstate heterojunction composite material loaded with sulfur indium copper quantum dots and its preparation method and application

A composite material and quantum dot technology, applied in the field of bismuth tungstate heterojunction composite materials, can solve the problems of constraints, narrow spectral response range, fast photo-generated electron-hole recombination speed, etc., to promote effective separation, large application potential, The effect of green and environmental protection in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

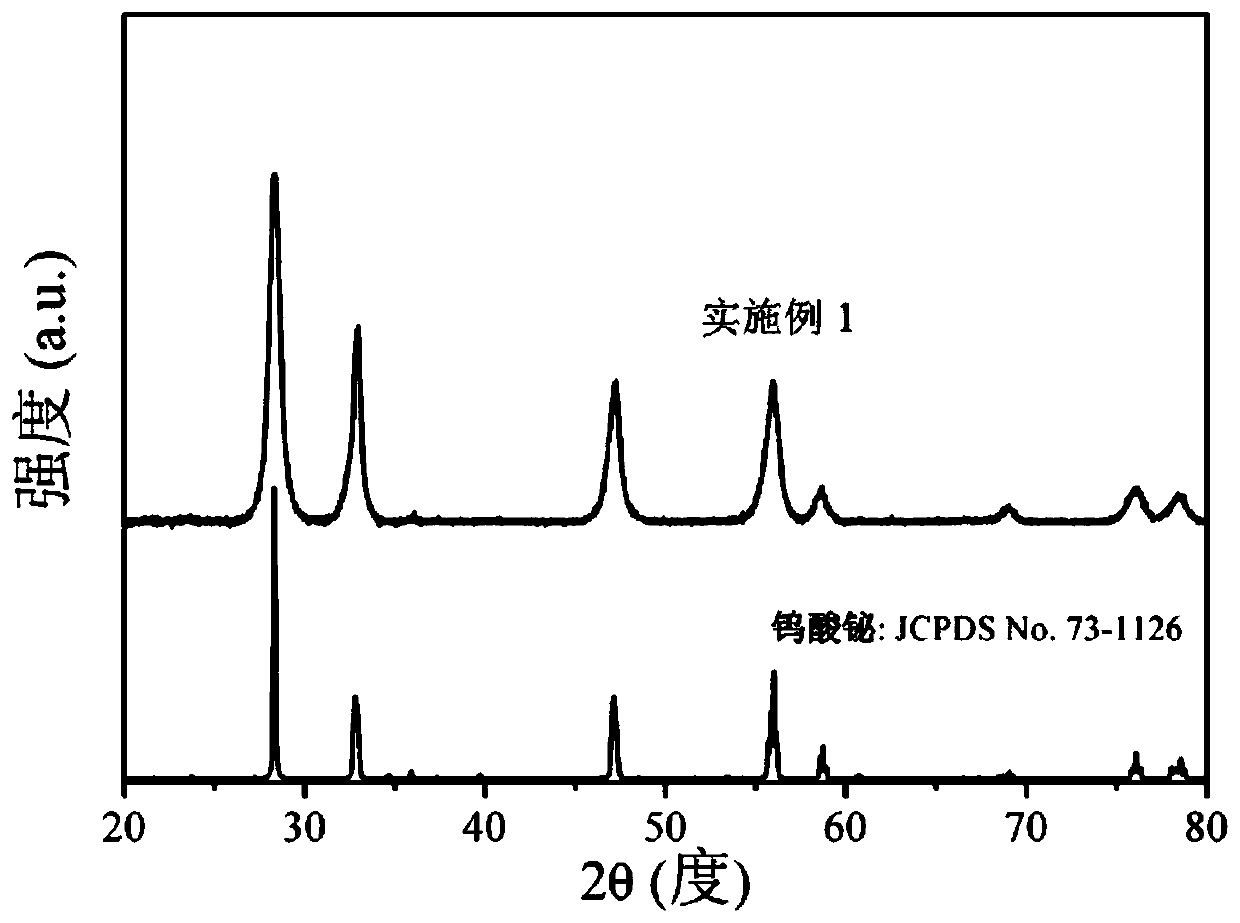

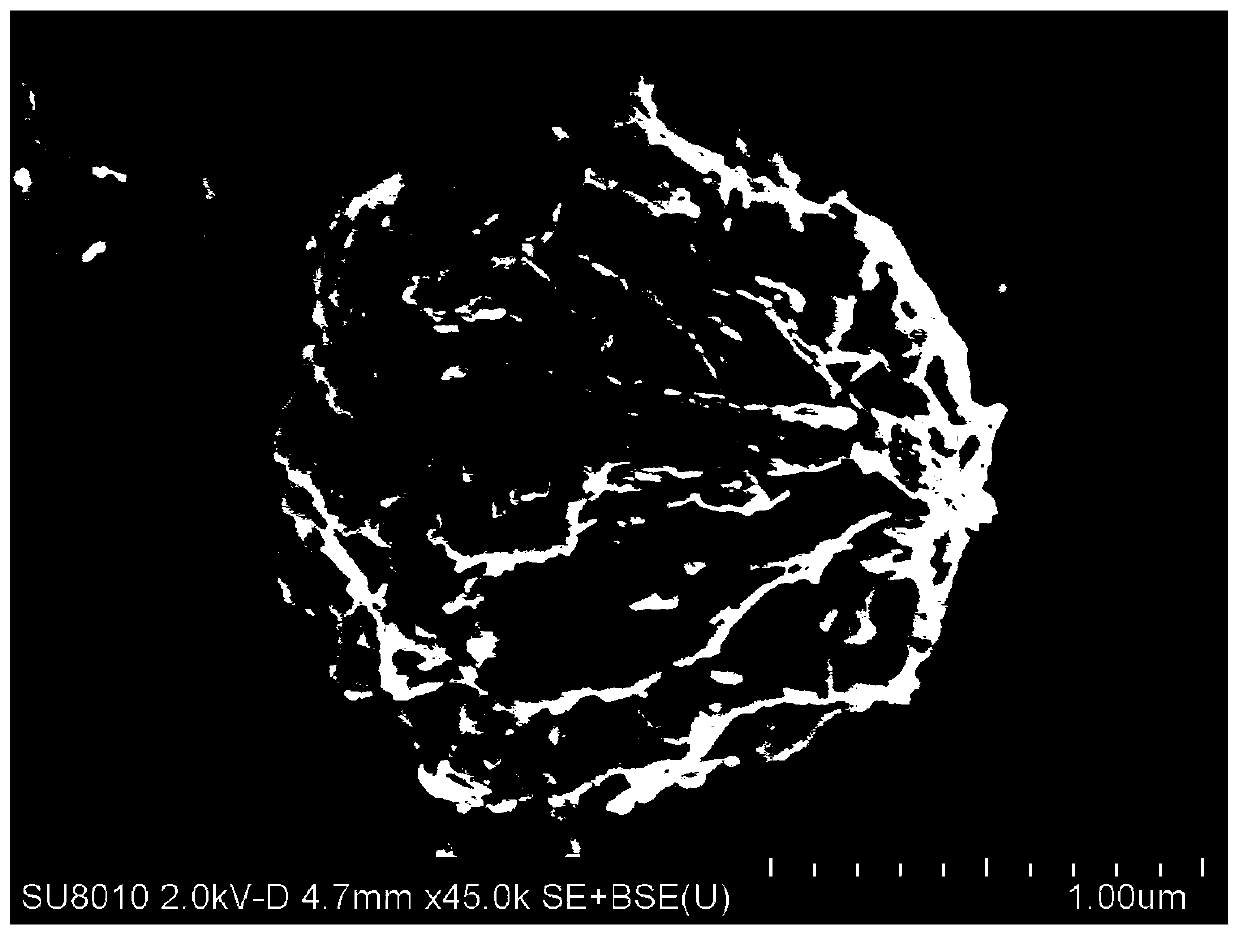

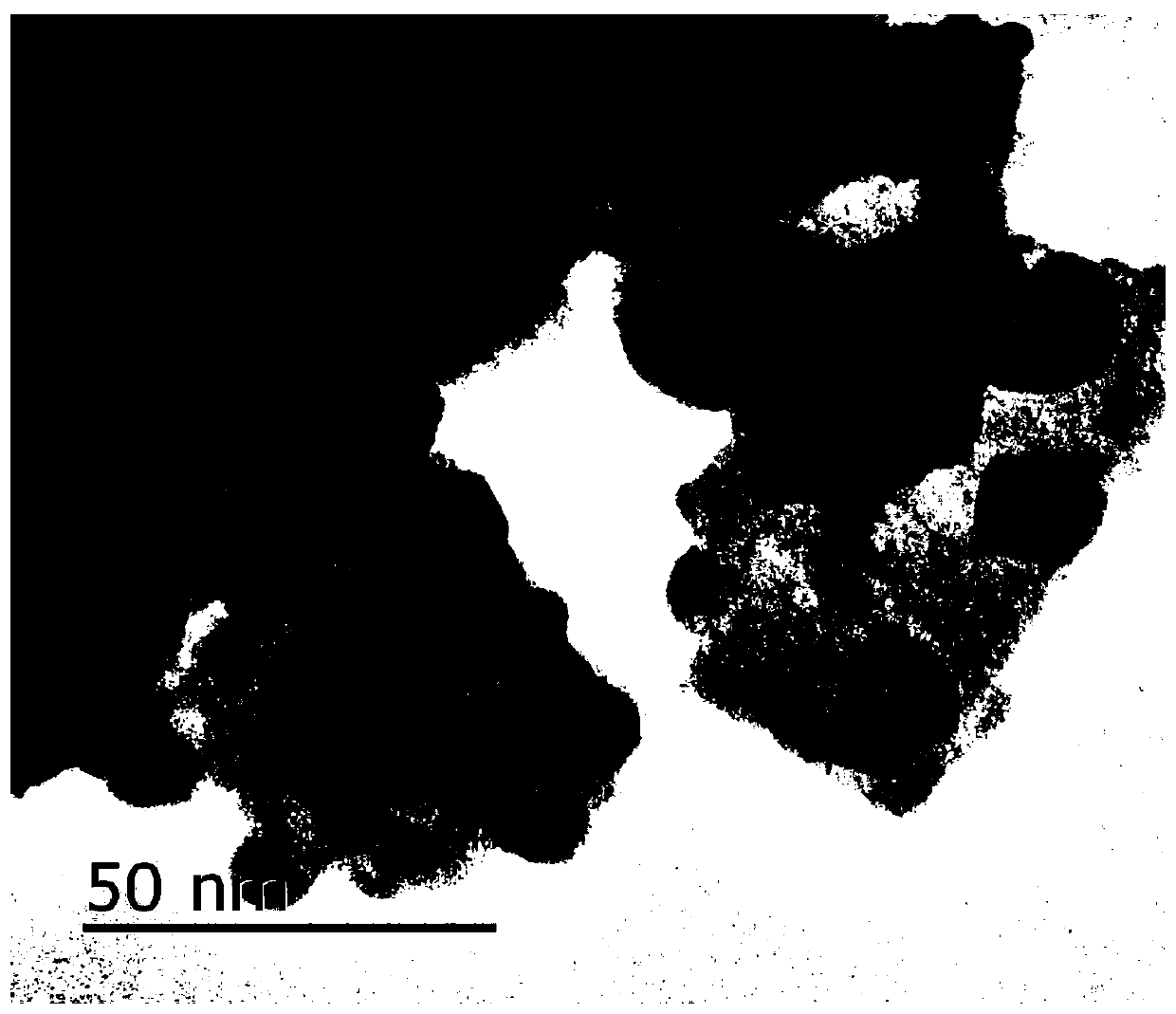

Embodiment 1

[0036] A bismuth tungstate heterojunction composite material loaded with sulfur indium copper quantum dots, the preparation method of which comprises the following steps:

[0037] 1) Synthesis of flower-like bismuth tungstate: Dissolve 2mmol of bismuth nitrate pentahydrate in 40mL of dilute nitric acid (0.3M), add 20mL of sodium tungstate solution (0.05M) under stirring, and then add 20mL of sodium hydroxide solution (0.8M ), stirred for 24 hours, placed the reaction solution in a stainless steel autoclave lined with polytetrafluoroethylene, heated to 160°C for hydrothermal reaction for 8 hours, centrifuged, washed and dried, and cooled to obtain a flower-shaped multi-stage Structure bismuth tungstate (carrier);

[0038] 2) Synthesis of sulfur indium copper quantum dots: Dissolve 0.2mmol of cuprous chloride and 0.2mmol of indium chloride tetrahydrate in 2mL of dodecyl mercaptan and 12mL of octadecene; hours; cooled to room temperature under the protection of nitrogen, centrif...

Embodiment 2

[0043] A bismuth tungstate heterojunction composite material loaded with sulfur indium copper quantum dots, the specific preparation steps are as follows:

[0044] 1) Synthesis of flower-like bismuth tungstate: Dissolve 2mmol of bismuth nitrate pentahydrate in 40mL of dilute nitric acid (0.3M), add 20mL of sodium tungstate solution (0.05M) under stirring, and then add 20mL of sodium hydroxide solution (0.8M ), stirred for 24 hours, placed the reaction solution in a stainless steel autoclave lined with polytetrafluoroethylene, heated to 160°C for hydrothermal reaction for 8 hours, centrifuged, washed and dried, and cooled to obtain a flower-shaped multi-stage Structure bismuth tungstate (carrier);

[0045] 2) Synthesis of sulfur indium copper quantum dots: Dissolve 0.2mmol of cuprous chloride and 0.2mmol of indium chloride tetrahydrate in 2mL of dodecyl mercaptan and 12mL of octadecene; hours; cooled to room temperature under the protection of nitrogen, centrifuged, washed and...

Embodiment 3

[0050] A bismuth tungstate heterojunction composite material loaded with sulfur indium copper quantum dots, the specific preparation steps are as follows:

[0051] 1) Synthesis of flower-like bismuth tungstate: Dissolve 2mmol of bismuth nitrate pentahydrate in 40mL of dilute nitric acid (0.3M), add 20mL of sodium tungstate solution (0.05M) under stirring, and then add 20mL of sodium hydroxide solution (0.8M ), stirred for 24 hours, placed the reaction solution in a stainless steel autoclave lined with polytetrafluoroethylene, heated to 160°C for hydrothermal reaction for 8 hours, centrifuged, washed and dried, and cooled to obtain a flower-shaped multi-stage Structure bismuth tungstate (carrier);

[0052] 2) Synthesis of sulfur indium copper quantum dots: Dissolve 0.2mmol of cuprous chloride and 0.2mmol of indium chloride tetrahydrate in 2mL of dodecanethiol and 12mL of octadecene, and then raise the temperature to 220°C under the protection of nitrogen for reaction 2 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com