Filter aid for refined filtration of sodium aluminate solution and production and use method of filter aid

A production method, sodium aluminate technology, applied in chemical instruments and methods, separation methods, aluminate/alumina/aluminum hydroxide purification, etc., can solve the problems of consuming bauxite resources and lime resources, and achieve cost reduction Low cost, good performance, and the effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

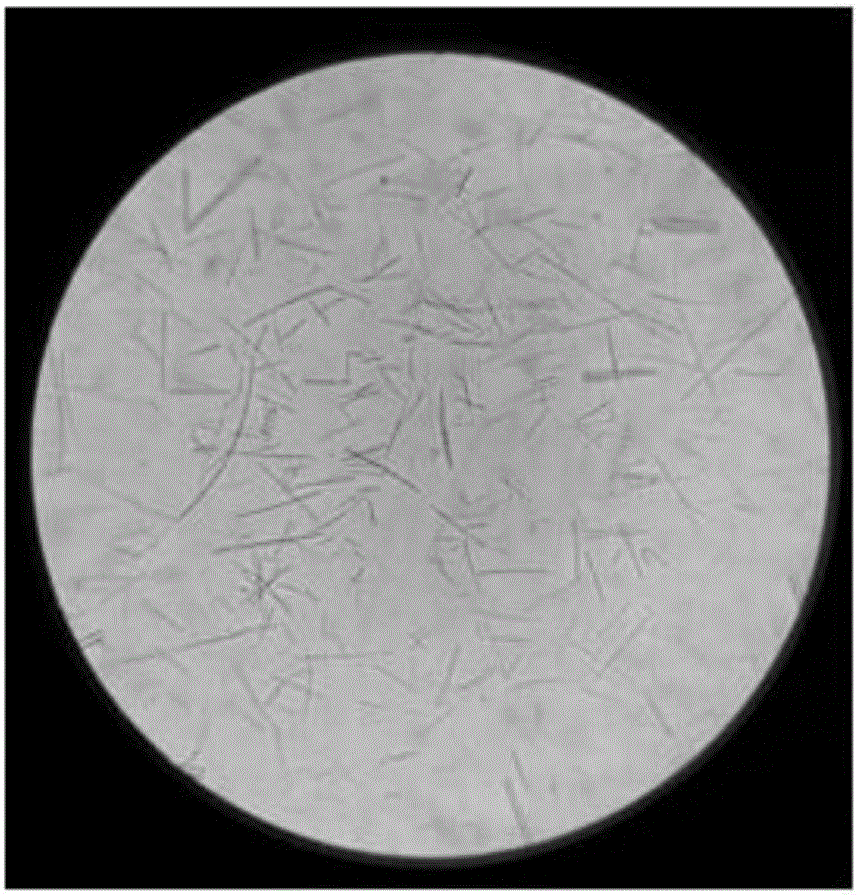

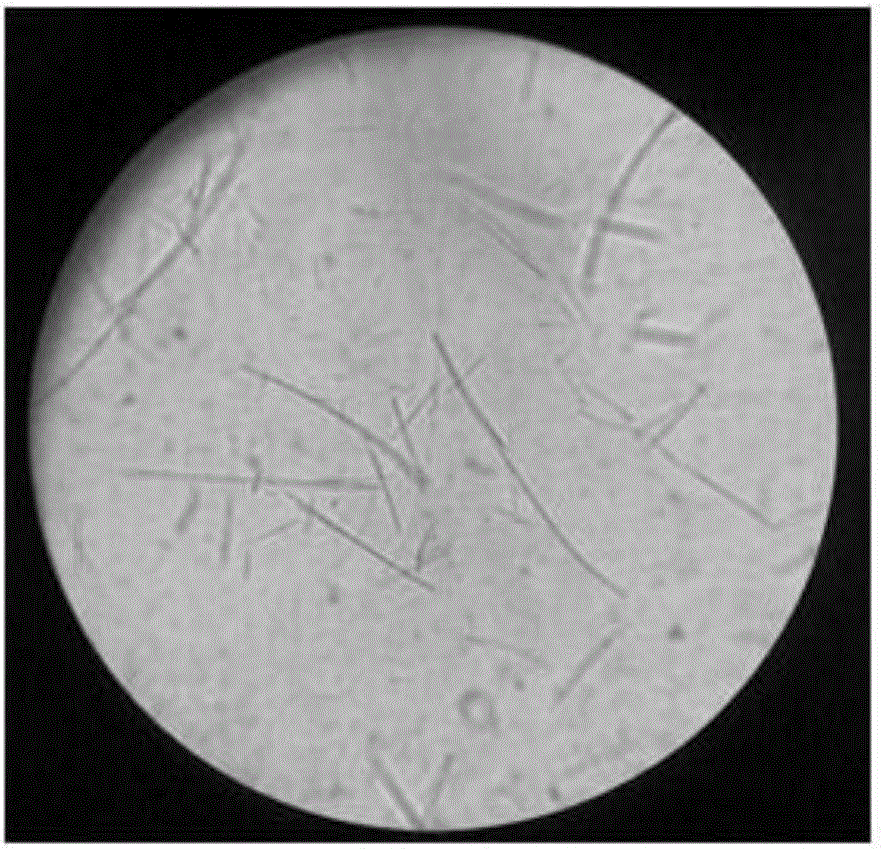

[0030] The filter aid used in the fine filtration of sodium aluminate solution in this embodiment is the α-phase calcium sulfate whisker, and the CaSO in the α-phase calcium sulfate whisker 4 Weight content ≥98%, whisker diameter 1-2μm, length 70-140μm, aspect ratio 70, D50 15μm, D90 / D10 2, water solubility at 22°C 3 , its microscopic image as figure 1 with figure 2 shown.

[0031] Its production method is carried out according to the following steps:

[0032] (1) by-products of flue gas desulfurization in coal-fired power plants, i.e. desulfurized gypsum, are uniformly mixed with water to make a slurry with a solid weight content of 2%;

[0033](2) at 80 DEG C, under the stirring condition of 100 revs / min, feed oxygen to the slurry of step (1), stop feeding oxygen after reacting for 30 minutes;

[0034] (3) The slurry after the reaction in the step (2) is sent into the autoclave, after adding the crystal form stabilizer magnesium chloride accounting for 0.2% of the slurr...

Embodiment 2

[0037] The filter aid used in the fine filtration of sodium aluminate solution in this embodiment is the α-phase calcium sulfate whisker, and the CaSO in the α-phase calcium sulfate whisker 4 Weight content ≥98%, average whisker diameter 2-4μm, length 100-150μm, average aspect ratio 60, D50 10μm, D90 / D10 3, water solubility at 22°C 3 .

[0038] Its production method is carried out according to the following steps:

[0039] (1) mixing the flue gas desulfurization by-product of sulfur mineral sintering, i.e. desulfurization gypsum, with water to make a slurry with a solid weight content of 5%;

[0040] (2) at 80 DEG C, under the stirring condition of 100 revs / min, feed oxygen to the slurry of step (1), stop feeding oxygen after reacting for 30 minutes;

[0041] (3) The slurry after the reaction in step (2) is sent into the autoclave, after adding the crystal form stabilizer EDTA accounting for 1% of the weight of the slurry after the reaction in the autoclave, at 120 ° C, the s...

Embodiment 3

[0044] The filter aid used in the fine filtration of sodium aluminate solution in this embodiment is the α-phase calcium sulfate whisker, and the CaSO in the α-phase calcium sulfate whisker 4 Weight content ≥98%, average diameter 0.2-2μm, length 30-150μm, average aspect ratio 70, D50 20μm, D90 / D10 2, water solubility at 22°C 3 .

[0045] Its production method is carried out according to the following steps:

[0046] (1) Mix the flue gas desulfurization by-product of sulfur-containing mineral sintering, that is, desulfurization gypsum and water evenly, and make a slurry with a solid weight content of 8%;

[0047] (2) at 80 DEG C, under the stirring condition of 100 revs / min, feed oxygen to the slurry of step (1), stop feeding oxygen after reacting for 30 minutes;

[0048] (3) the slurry after the reaction in the step (2) is sent into the autoclave, after adding the crystal form stabilizer sodium dodecylbenzenesulfonate accounting for 2% of the slurry weight after the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com