Manufacturing method of silver nanowire and manganous-manganic oxide one-dimensional core-shell composite nanomaterial

A technology of manganese tetroxide and silver nanowires is applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., which can solve the problems of poor conductivity, difficult adjustment of morphology, pore size and pore distribution, and unsatisfactory capacitance performance. Achieve the effect of good rate performance, suitable for large-scale production, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of a silver nanowire and manganese manganese tetraoxide one-dimensional core-shell nanocomposite, the steps are as follows:

[0021] 1) Add 1mL of silver nanowire-ethanol dispersion with a concentration of 5mg / mL into 50mL of absolute ethanol, stir magnetically to disperse evenly, and obtain a mixed solution;

[0022] 2) Add 1.670ml L concentration of 30mg / mL potassium permanganate solution dropwise to the above mixture, keep magnetic stirring at room temperature for 12 hours, wash with deionized water and absolute ethanol for 3 times, and vacuum dry at 60°C 12 hours, obtain brown powder;

[0023] 3) Put the above-mentioned brown powder in a tube furnace, calcinate at 400°C for 2 hours at a heating rate of 10°C per minute under an argon atmosphere, and cool naturally to room temperature to obtain silver nanowires and trioxide tetroxide Manganese one-dimensional core-shell composite nanomaterials.

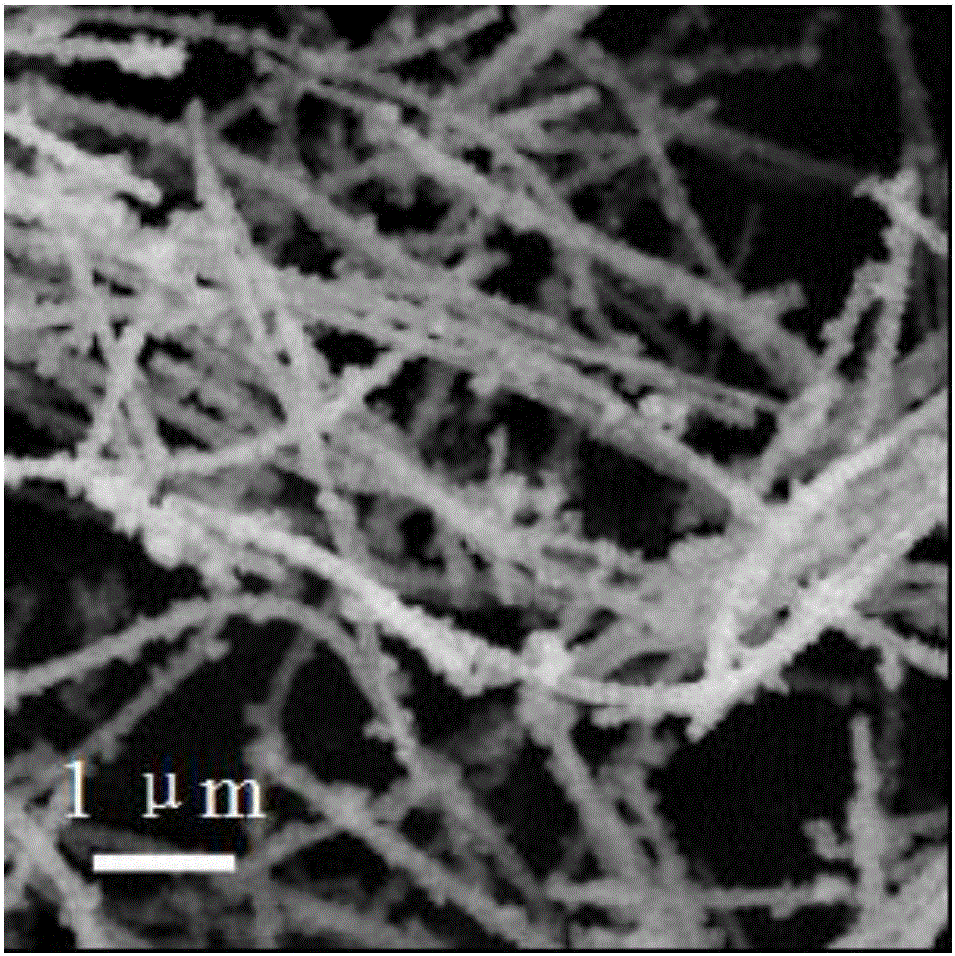

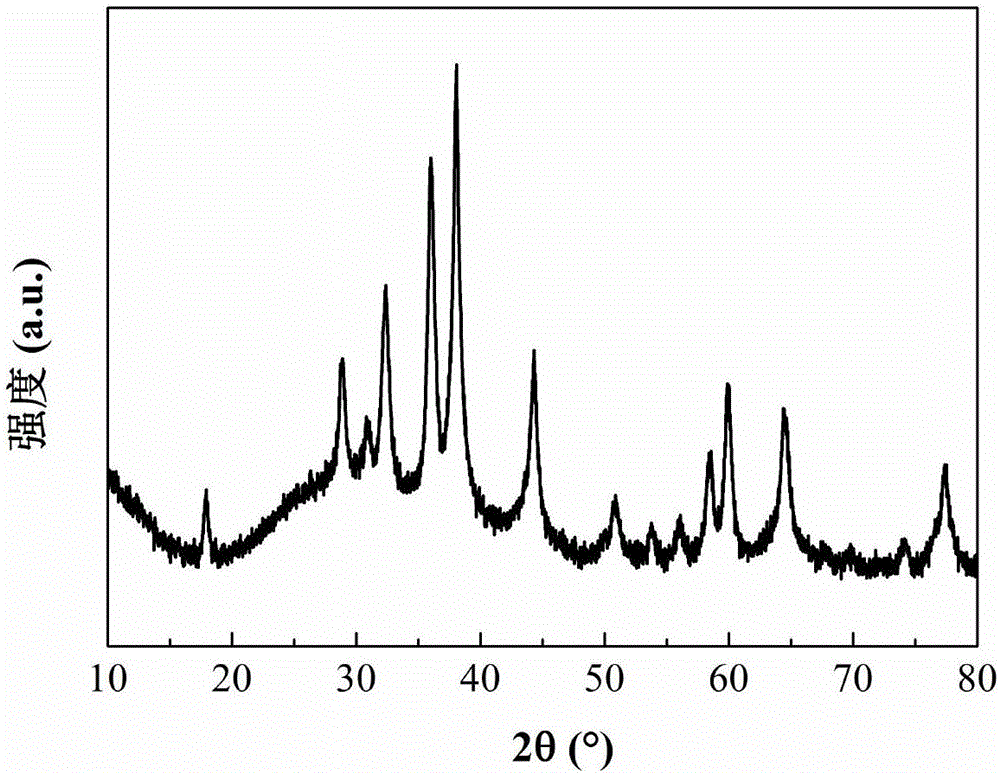

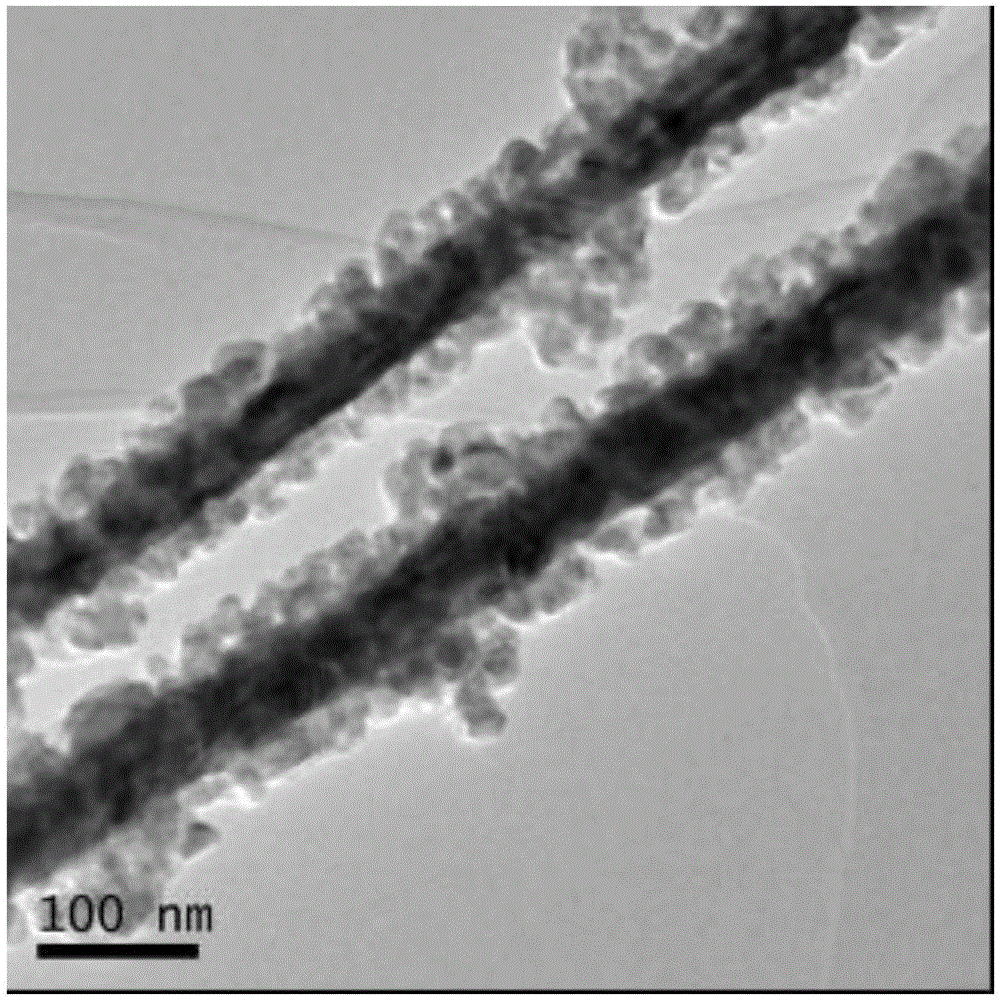

[0024] figure 1 It is the SEM picture of silver ...

Embodiment 2

[0031] A preparation method of a silver nanowire and manganese manganese tetraoxide one-dimensional core-shell nanocomposite, the steps are as follows:

[0032] 1) Add 1mL of silver nanowire-ethanol dispersion with a concentration of 5mg / mL into 50mL of absolute ethanol, stir magnetically to disperse evenly, and obtain a mixed solution;

[0033] 2) Add 1.670 mL of potassium permanganate solution with a concentration of 30 mg / mL dropwise to the above mixture, keep magnetic stirring at room temperature for 12 hours, wash with deionized water and absolute ethanol for 3 times, and vacuum dry at 60 °C 12 hours, obtain brown powder;

[0034] 3) Put the above-mentioned brown powder in a tube furnace, calcinate at 300°C for 2 hours at a heating rate of 10°C per minute under an argon atmosphere, and cool naturally to room temperature to obtain silver nanowires and trioxide tetroxide Manganese one-dimensional core-shell composite nanomaterials.

[0035] The prepared silver nanowire an...

Embodiment 3

[0037] A preparation method of a silver nanowire and manganese manganese tetraoxide one-dimensional core-shell nanocomposite, the steps are as follows:

[0038] 1) Add 1mL of silver nanowire-ethanol dispersion with a concentration of 5mg / mL into 50mL of absolute ethanol, stir magnetically to disperse evenly, and obtain a mixed solution;

[0039] 2) Add 1.670mL potassium permanganate solution with a concentration of 30mg / mlL dropwise to the above mixture, keep magnetic stirring at room temperature for 12 hours, wash with deionized water and absolute ethanol for 3 times, and vacuum dry at 60°C 12 hours, obtain brown powder;

[0040] 3) Put the above-mentioned brown powder in a tube furnace, calcinate at 200°C for 2 hours at a heating rate of 10°C per minute under an argon atmosphere, and cool naturally to room temperature to obtain silver nanowires and trioxide tetroxide Manganese one-dimensional core-shell composite nanomaterials.

[0041] The prepared silver nanowire and tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com