Mold guiding plate for growing sapphire crystals by virtue of EFG method

A technology of sapphire crystal and guide template, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc. It can solve problems such as high temperature, difficult feeding, inconsistent crystal width, and reduced drawing speed, so as to achieve increased control and adjustment Range, solve crystal shrinkage, increase the effect of local width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be explained in more detail with reference to the following examples; however, the present invention is not limited to these examples.

[0030] It should be noted that the position description relationship (ie up, down, left, right, front, back) used in the present invention is only an example of the accompanying drawings.

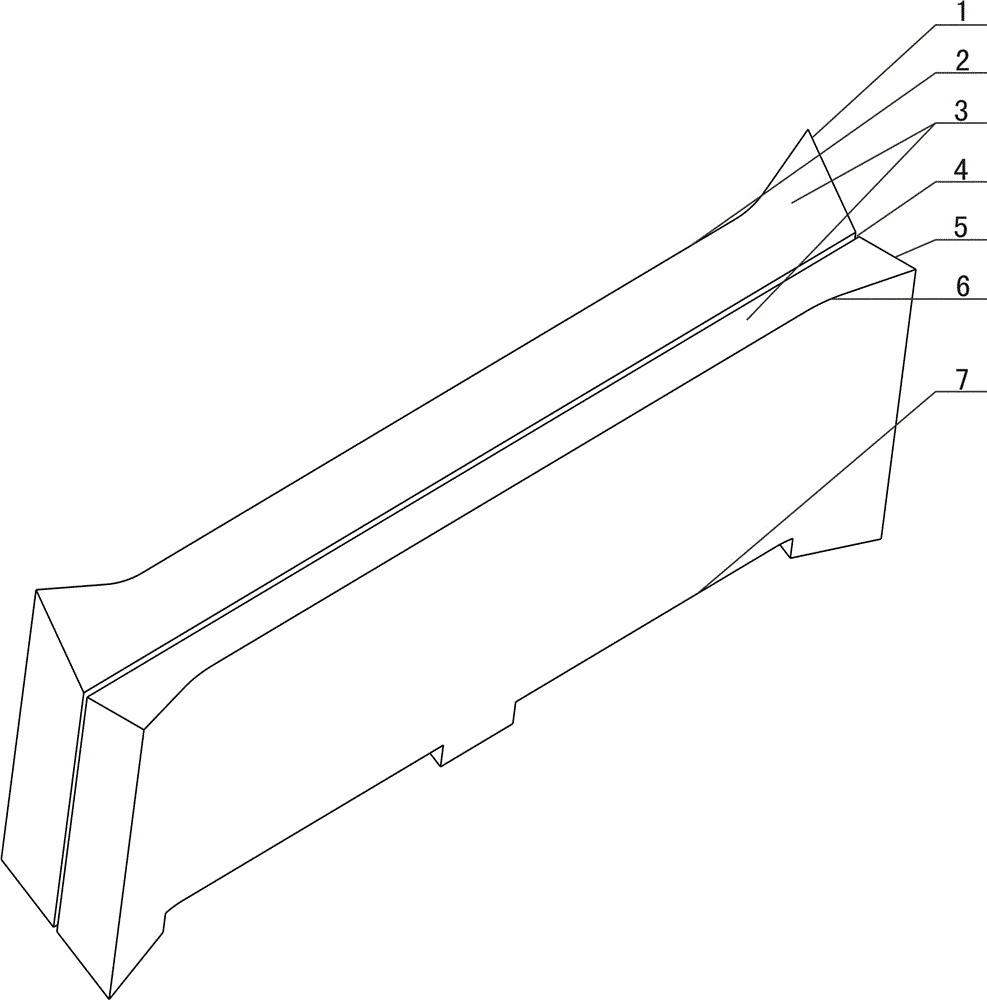

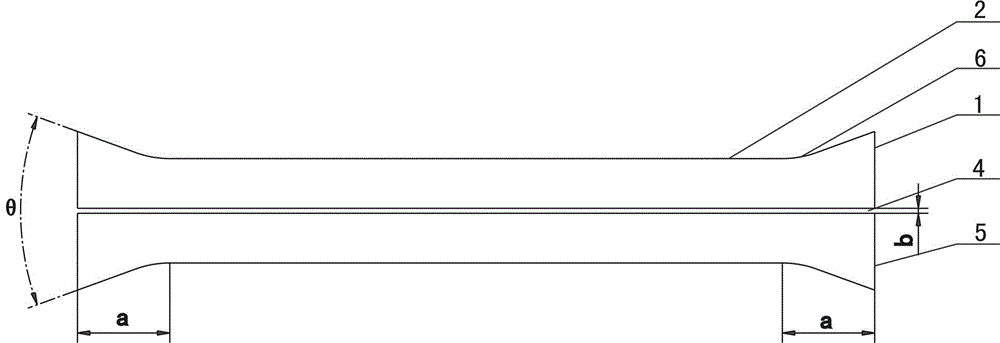

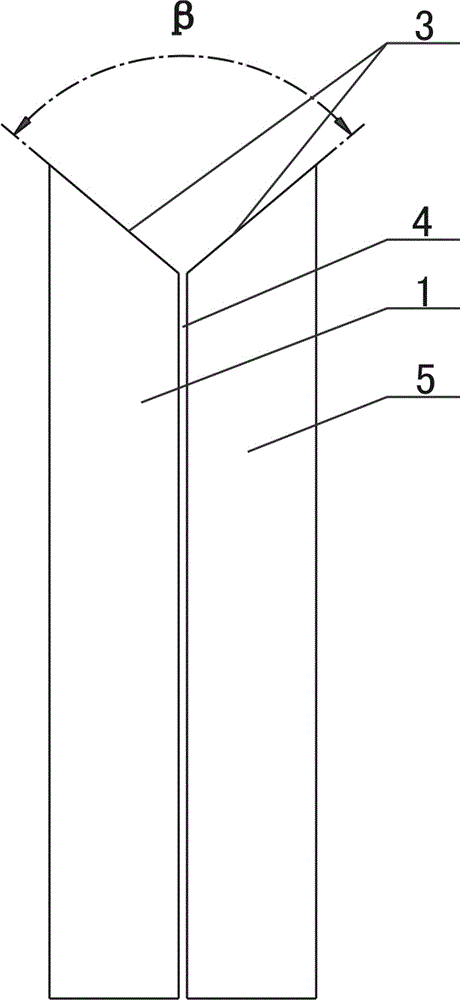

[0031] combined with Figure 1~3 The described guide plate for growing sapphire crystal by the guide mode method comprises a first side plate 1, a concave surface 2, a main feed slot 4 and a second side plate 5, and the first side plate 1 and the second side plate The shapes of the boards 5 are all rectangular structures, the length, width and thickness of the first side board 1 and the second side board 5 are set to be consistent, and the first side board 1 and the second side board 5 are arranged in parallel, correspondingly and at intervals to form a rectangle The main body of the guide plate, the gap between the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com