Silicon dioxide aerogel mortar and preparation method thereof

A silica and aerogel technology, used in the field of mortar preparation, can solve the problems of low flexural strength and bonding strength, material brittleness, non-load cracks, etc., to increase frost resistance and impermeability, The effect of improving the durability of mortar bonding and improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

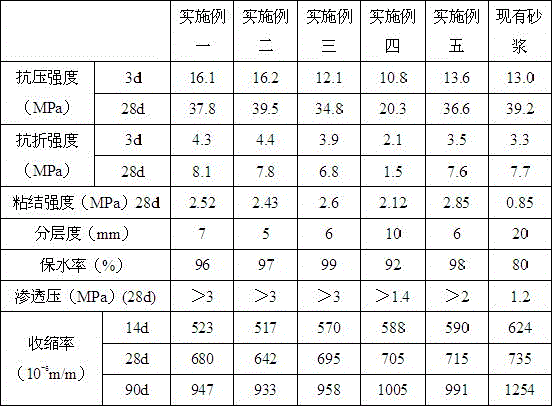

Embodiment 1

[0020] Embodiment 1: A kind of silica airgel mortar of the present embodiment includes the following components according to the weight fraction ratio: 100 parts of cement, 300 parts of sand, 0.2 part of defoamer, silica airgel microspheres 10 parts, 25 parts of ethyl acrylate emulsion, 0.02 parts of polymer powder, 5 parts of water, 15 parts of mineral micropowder, 0.2 parts of water reducer;

[0021] The polymer powder includes methyl cellulose and dispersible rubber powder, and the weight ratio of methyl cellulose and dispersible rubber powder is 2:1.

[0022] The mineral fine powder includes mineral powder, limestone powder and fly ash, and the weight ratio range of mineral powder, limestone powder and fly ash is 1:1.2:1.5;

[0023] The sand has a modulus of fineness of 2.3.

[0024] The fineness of the cement is less than or equal to 2.5% with a sieve residue of 80 μm.

[0025] A preparation method for silica airgel mortar, comprising the following steps:

[0026] Step...

Embodiment 2

[0030] Embodiment 2: A kind of silica airgel mortar of the present embodiment comprises the following components according to weight fraction ratio: 100 parts of cement, 300 parts of sand, 0.2 part of defoamer, silica airgel microspheres 15 parts, 30 parts of ethyl acrylate emulsion, 0.5 parts of polymer powder, 6 parts of water, 20 parts of mineral micropowder, 0.4 parts of water reducing agent;

[0031] The polymer powder includes methyl cellulose and dispersible rubber powder, and the weight ratio of methyl cellulose and dispersible rubber powder is 2:1.

[0032] The mineral fine powder includes mineral powder, limestone powder and fly ash, and the weight ratio range of mineral powder, limestone powder and fly ash is 1:1.2:1.5;

[0033] The sand has a modulus of fineness of 2.3.

[0034] The fineness of the cement is less than or equal to 2.5% with a sieve residue of 80 μm.

[0035] A preparation method for silica airgel mortar, comprising the following steps:

[0036] S...

Embodiment 3

[0040] Embodiment three: a kind of silica airgel mortar of the present embodiment comprises the following components according to the weight fraction ratio: 100 parts of cement, 300 parts of sand, 0.2 part of defoamer, silica airgel microspheres 20 parts, 40 parts of ethyl acrylate emulsion, 0.1 part of polymer powder, 7 parts of water, 30 parts of mineral micropowder, 0.8 part of water reducer;

[0041] The polymer powder includes methyl cellulose and dispersible rubber powder, and the weight ratio of methyl cellulose and dispersible rubber powder is 2:1.

[0042] The mineral fine powder includes mineral powder, limestone powder and fly ash, and the weight ratio range of mineral powder, limestone powder and fly ash is 1:1.2:1.5;

[0043] The fineness modulus of the sand ranges from 2.2 to 2.6.

[0044] The fineness of the cement is less than or equal to 2.5% with a sieve residue of 80 μm.

[0045] A preparation method for silica airgel mortar, comprising the following steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com