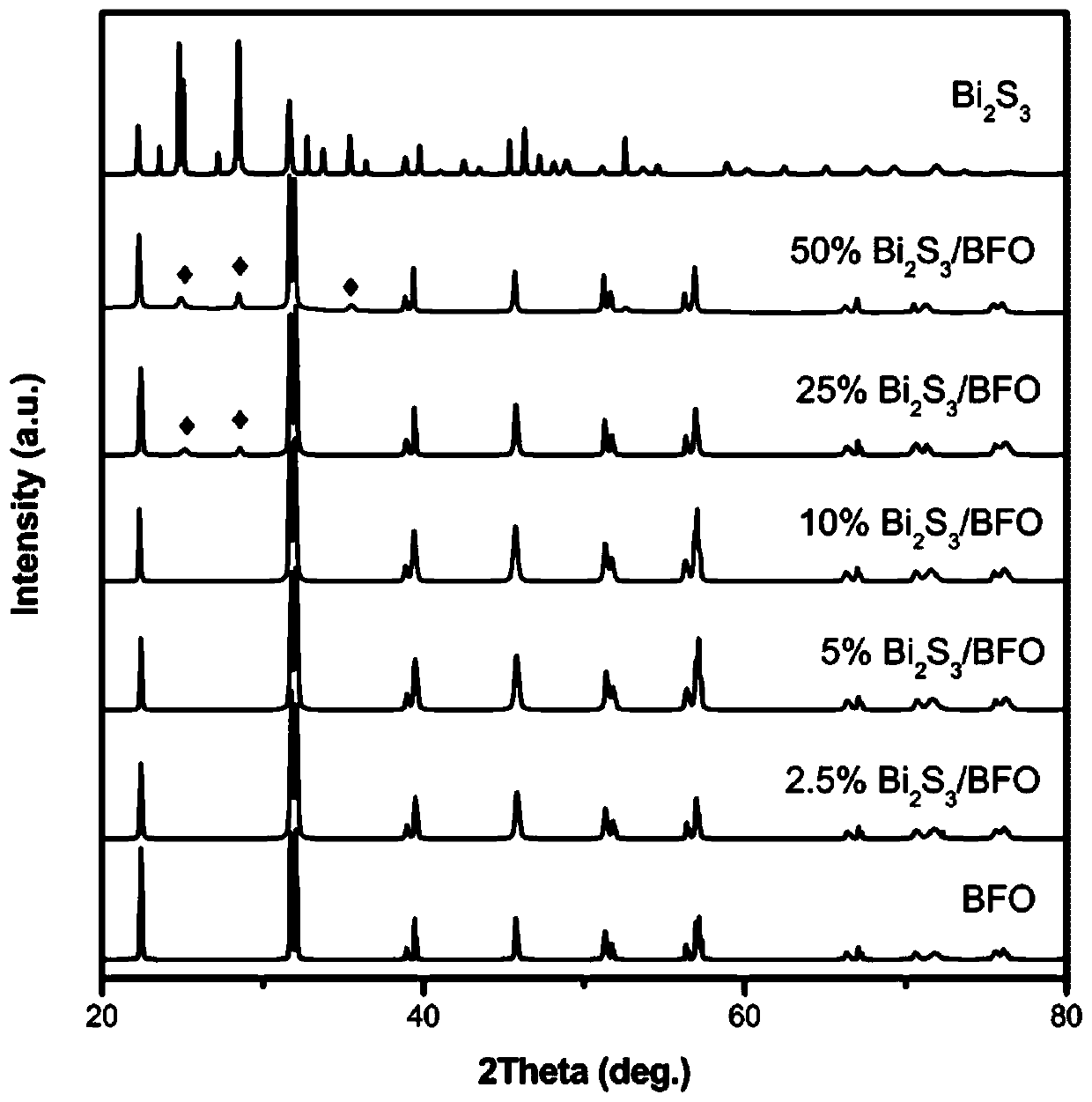

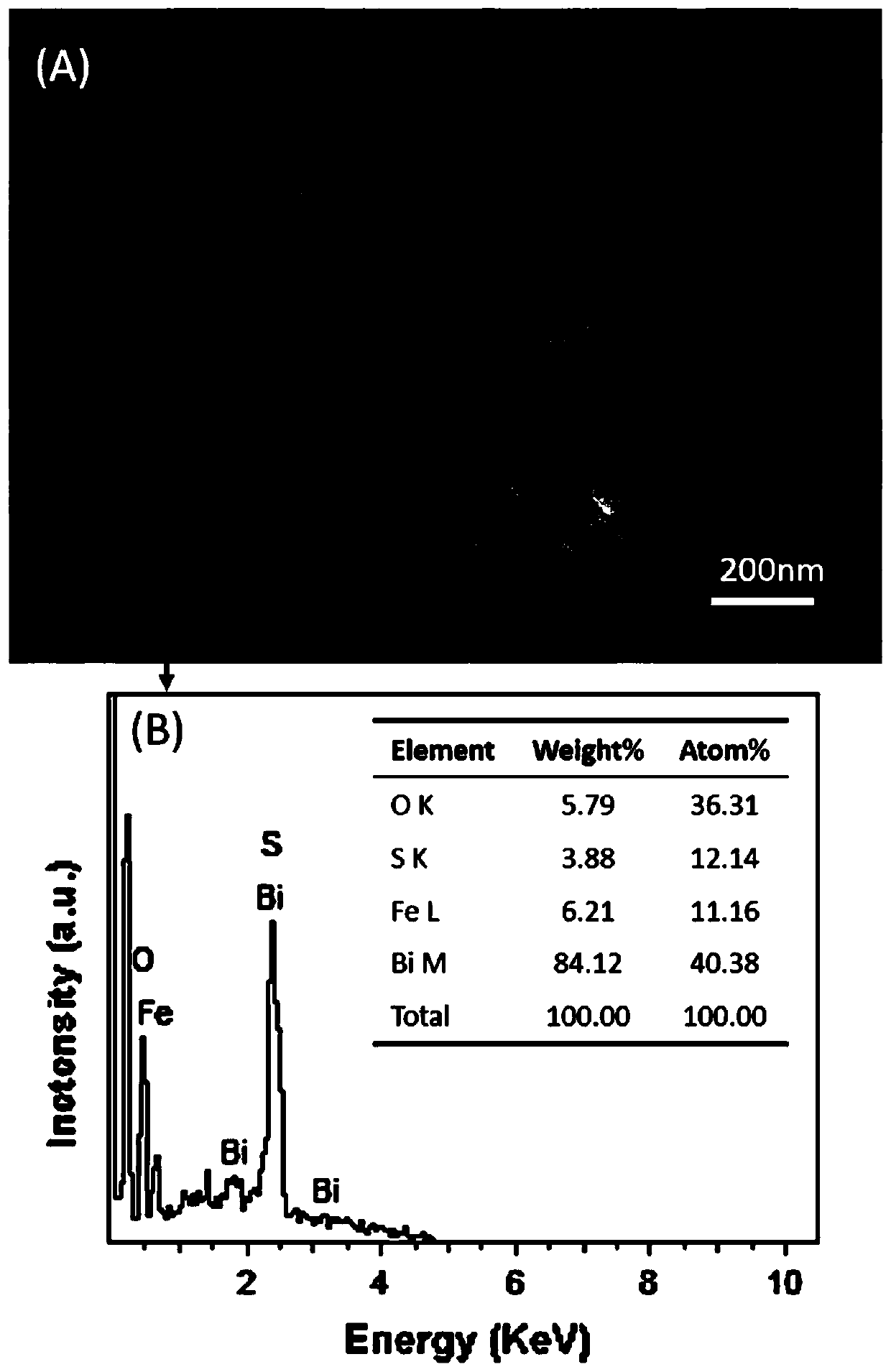

Preparation method and application of bismuth sulfide-bismuth ferrite composite visible light catalyst

A technology of bismuth ferrite and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unsatisfactory photocatalytic activity and high recombination rate of photogenerated carriers, and achieve convenient industrialization The effect of promotion, high catalytic activity and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of bismuth sulfide-bismuth ferrite composite visible light catalyst, the steps of its preparation method are as follows:

[0035] 1) Using bismuth source and iron source as raw materials, mix and dissolve them in the organic solvent ethylene glycol according to the molar ratio of bismuth and iron elements at a ratio of 1:1 to prepare a precursor liquid, and ultrasonically disperse at 60°C for 0.5 h, obtaining a sol, the molar ratio of the bismuth element in the bismuth source and the iron element in the iron source is 1:1; the bismuth source is bismuth nitrate and hydrate thereof, and the iron source is iron nitrate and hydrate thereof;

[0036]2) drying the prepared sol at 120° C. for 4-5 days to obtain xerogel powder;

[0037] 3) After grinding the obtained xerogel powder evenly, put it into a muffle furnace for pretreatment; the treatment temperature is 300°C, and the time is 2h;

[0038] 4) Calcining the pretreated xerogel powder in a muffle furnace at a tem...

Embodiment 2

[0042] A kind of bismuth sulfide-bismuth ferrite composite visible light catalyst, the steps of its preparation method are as follows:

[0043] 1) Using bismuth source and iron source as raw materials, mix and dissolve the two in proportion to the organic solvent ethylene glycol to prepare a precursor solution, and ultrasonically disperse at a temperature of 75°C for 1 hour to obtain a sol. The bismuth in the bismuth source The molar ratio of the iron element in the element and the iron source is 1:1; the bismuth source is bismuth nitrate and hydrate thereof, and the iron source is iron nitrate and hydrate thereof;

[0044] 2) drying the prepared sol at 125° C. for 4 days to obtain xerogel powder;

[0045] 3) After grinding the obtained xerogel powder evenly, put it into a muffle furnace for pretreatment; the treatment temperature is 350°C, and the time is 2h;

[0046] 4) The pretreated xerogel powder was calcined in a muffle furnace at a temperature of 550° C. for 3 hours, t...

Embodiment 3

[0050] A kind of bismuth sulfide-bismuth ferrite composite visible light catalyst, the steps of its preparation method are as follows:

[0051] 1) Using bismuth source and iron source as raw materials, mix and dissolve the two in proportion to the organic solvent ethylene glycol to prepare a precursor solution, and ultrasonically disperse at 80°C for 1 hour to obtain a sol. The bismuth in the bismuth source The molar ratio of the iron element in the element and the iron source is 1:1; the bismuth source is bismuth nitrate and hydrate thereof, and the iron source is iron nitrate and hydrate thereof;

[0052] 2) drying the prepared sol at 120° C. for 5 days to obtain xerogel powder;

[0053] 3) After grinding the obtained xerogel powder evenly, put it into a muffle furnace for pretreatment; the treatment temperature is 350°C, and the time is 3h;

[0054] 4) The pretreated xerogel powder was calcined in a muffle furnace at a temperature of 600° C. for 2 hours, then cooled to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com